Start-up evacuate and dehydrate, Leak test, Before starting unit – Carrier 38AE User Manual

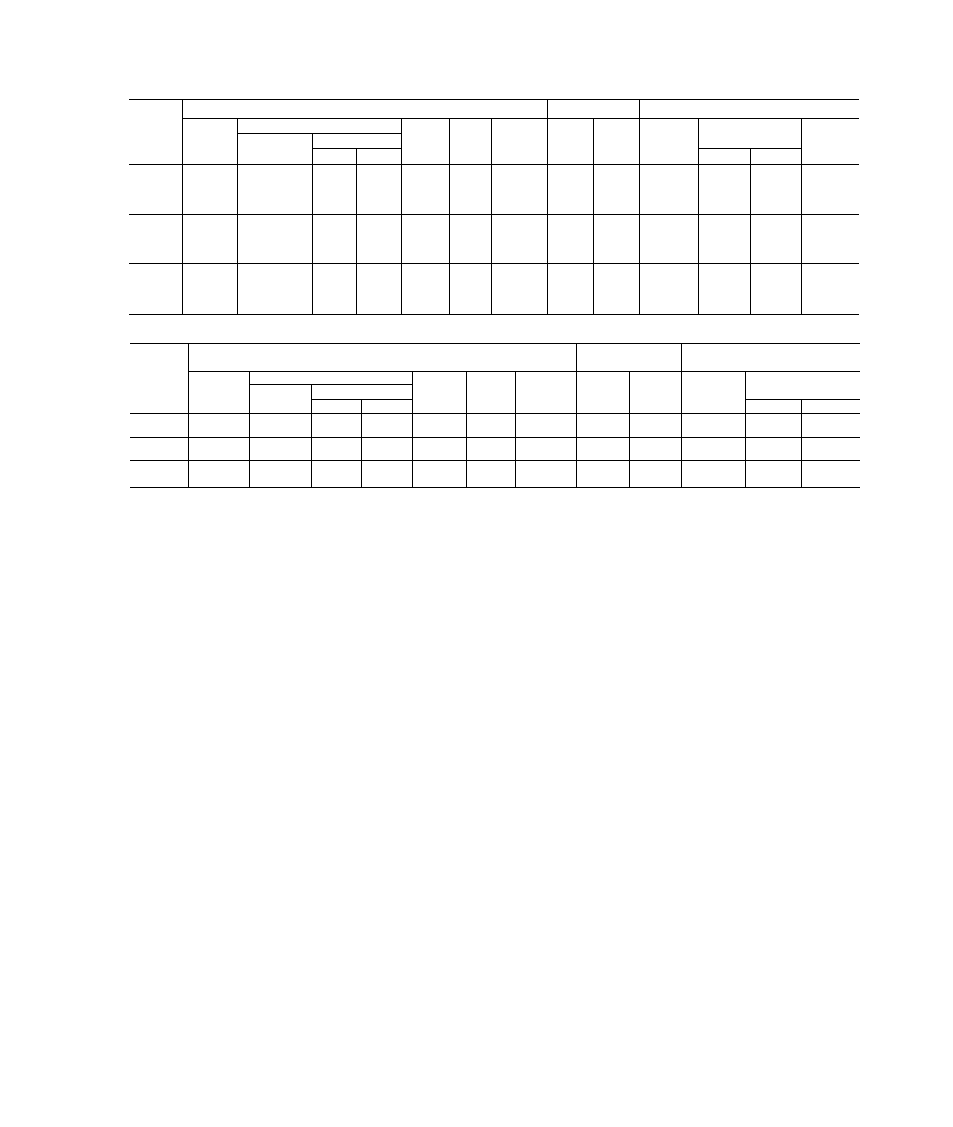

Page 5: Table 4 - electrical data

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

(3 Ph/60 Hz)

Table 4 - Electrical Data

UNIT

38AE

UNIT

COMPR

FAN MOTORS (Single Phase)

Model

Volts

MCA

ICF

MOCP

(Fuse)

RLA

LRA

Total

Fans

FLA (ea)

Fan No.

kW

Nameplate

Supplied*

Min

Max

1

2

501

208-230

187

253

62.5

178

100

43 6

170

4.3

37

012

201

380

342

418

35.0

101

50

24 0

93

4.3

37

601

460

414

528

29 1

81

40

20.0

77

23

1 9

101

575

518

660

22.8

67

35

157

62

1.8

1.8

501

208-230

187

253

69.3

199

100

49 3

191

43

37

201

380

342

418

38 0

112

60

26 5

104

43

37

601

460

414

528

31 7

84

50

22 1

80

23

1 9

101

575

518

660

25.6

73

40

17.9

69

1.8

1.8

501

208-230

187

253

87 5

274

125

63 6

266

43

37

201

380

342

418

49 3

153

80

36.0

145

43

37

601

460

414

528

40 7

124

60

29 3

120

2.3

1 9

101

575

518

660

33 0

100

50

23 8

96

1.8

1 8

(3 Ph/50 Hz)

UNIT

38AE

UNIT

COMPR

FAN MOTORS

230 V (Single Phase)

Model

Volts

MCA

ICF

MOCP

(Fuse)

RLA

LRA

Total

Fans

FLA (ea)

Fan No.

Name-

plate

Supplied*

Min

Max

1

2

803

230

198

264

47 5

134

75

32 9

128

29

35

903

400

342

457

31 4

80

50

20.0

74

2.9

3.5

803

230

198

264

51 0

149

75

35 7

143

29

3.5

903

400

342

457

34 0

89

50

22 1

83

29

3.5

803

230

198

264

66 9

206

100

47 9

200

2.9

35

903

400

342

457

43 0

121

60

29 3

115

29

35

FLA —

Full Load Amps (Fan Motors)

ICF —

Maximum Instantaneous Current Flow during start-up (LRA of compressor plus total FLA of fan motors)

kW —

Total Fan Motor Input (kilowatts)

LRA —

Looked Rotor Amps

MCA —

Minimum Circuit Amps per NEC (U S.A ), Section 430-24

MOCP —

Maximum Overcurrent Protection (amps)

RLA —

Rated Load Amps (Compressor)

•Units are suitable for use on electrical systems where voltage supplied to the unit terminals is not below or above

the listed limits

START-UP

Evacuate and Dehydrate

the entire refrigerant sys

tem by either of the methods described in Carrier Standard

Service Techniques Manual, Chapter 1, Section 1-7.

Leak Test

the entire refrigerant system by the pressure

method described in Carrier Standard Service Techniques

Manual, Chapter 1, Section 1-6. Use R-22 at approxi

mately 25 psig (172.4 kPa) backed up with an inert gas to

a total pressme not to exceed 245 psig (1689 kPa).

Before starting the unit, the crankcase heaters must be

on for 24 hours to be sure all the refrigerant is out of the

oil.

To energize the crankcase heaters, proceed as follows.

1. Set the space thermostat above ambient so there will be

no demand for cooling.

2. Close the field disconnect.

3. Turn the fan circuit breaker on. Leave the compressor

circuit breakers off. The crankcase heaters are now

energized.

Before Starting Unit

check the following:

1. Compressor oil level must be at least within sight in the

compressor sight glass. Add oil if necessary (see Table

1 and Oil Charge section).

2. Compressor holddown bolts must be snug, but not tight.

Refer to Compressor Mounting section and tag on com

pressor foot.

3. All internal wiring connections must be tight; all barri

ers and covers must be in place.

4. Electrical power source must agree with unit nameplate

rating.

5. All service valves must be open.

6. Crankcase heater must be firmly locked into the com

pressor crankcase.