Carrier 07E User Manual

Page 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Check low-pressure switch by slowly closing

suction shutoff valve or by completely closing

hquid line shutoff valve. A decrease of suction

pressure will follow. Compressor should shut off

within 4 psi of values shown in Table 1.

HIGH-PRESSURE

SAFETY SWITCH

LOW-PRESSURE

SAFETY SWITCH

RANGE ADJUSTMENT-TURN

CLOCKWISE TO RAISE BOTH

CUT-IN AND CUTOUT

DIFFERENTIAL ADJUSTMENT -TURN

■ № ■' CLOCKWISE TO DECREASE ONLY LOWER

SETTING WITHOUT CHANGING THE

HIGHER SETTING

*Hlgh — 38 PsI/Turn

Low — 7 Psi/Turn

Fig. 8 — Dual Pressurestat Adjustment

Time Guard Circuit

for each compressor provides

for a 5-minute delay before restarting compressor

after shutdown for any reason. On starting, the

Time Guard Timer causes a delay of 15 seconds

after thermostat closes before compressor will

start. On compressor shutdown, the timer recycles

for 4 minutes 45 seconds. During this time the

compressor cannot restart.

Compressor Motor Protection

on 06EW027,

06EW044, 07EB027 and 07ED044 consists of

three temperature sensors embedded in motor

windings and connected to a solid state module in

unit control box.

When an over-temperature condition causes

module to shut compressor off, push control

center STOP button. Investigate cause of com

pressor shutdown and correct. After compressor

cools (see Temperature Sensors below), push

ST ART-RESET button. Compressor will restart

after Time Guard delay period.

SOLID STATE MODULE is checked by applying

unit control voltage to terminals T1 and T2 (see

label diagram), then checking for continuity across

terminals Ml and M2. If no continuity between Ml

and M2, check temperature sensor and fuse resist

ance using a volt-ohmmeter (see below).

CAUTION; Do not use a fcattiary powered test

lamp

to check sensors. Excessive current can

cause damage.

TEMPERATURE SENSORS are protected by

three 1/8-amp fuses (Carrier Part no. HYIOLFOIO)

in compressor terminal box. Fuse resistance should

be between 3.2 and 4.4 ohms. Replace defective

fuses only with 1/8-amp fuses specified above. If

all sensors check below 95 ohms (180 F), fuses are

good, and there is no continuity between module

terminals Ml and M2, replace module.

If one sensor fails, it can be jumpered out of

the circuit with a 75 ohm, 2-watt resistor across

the proper sensor terminal and common terminal.

If a short to ground in sensor circuit is indicated,

replace compressor motor.

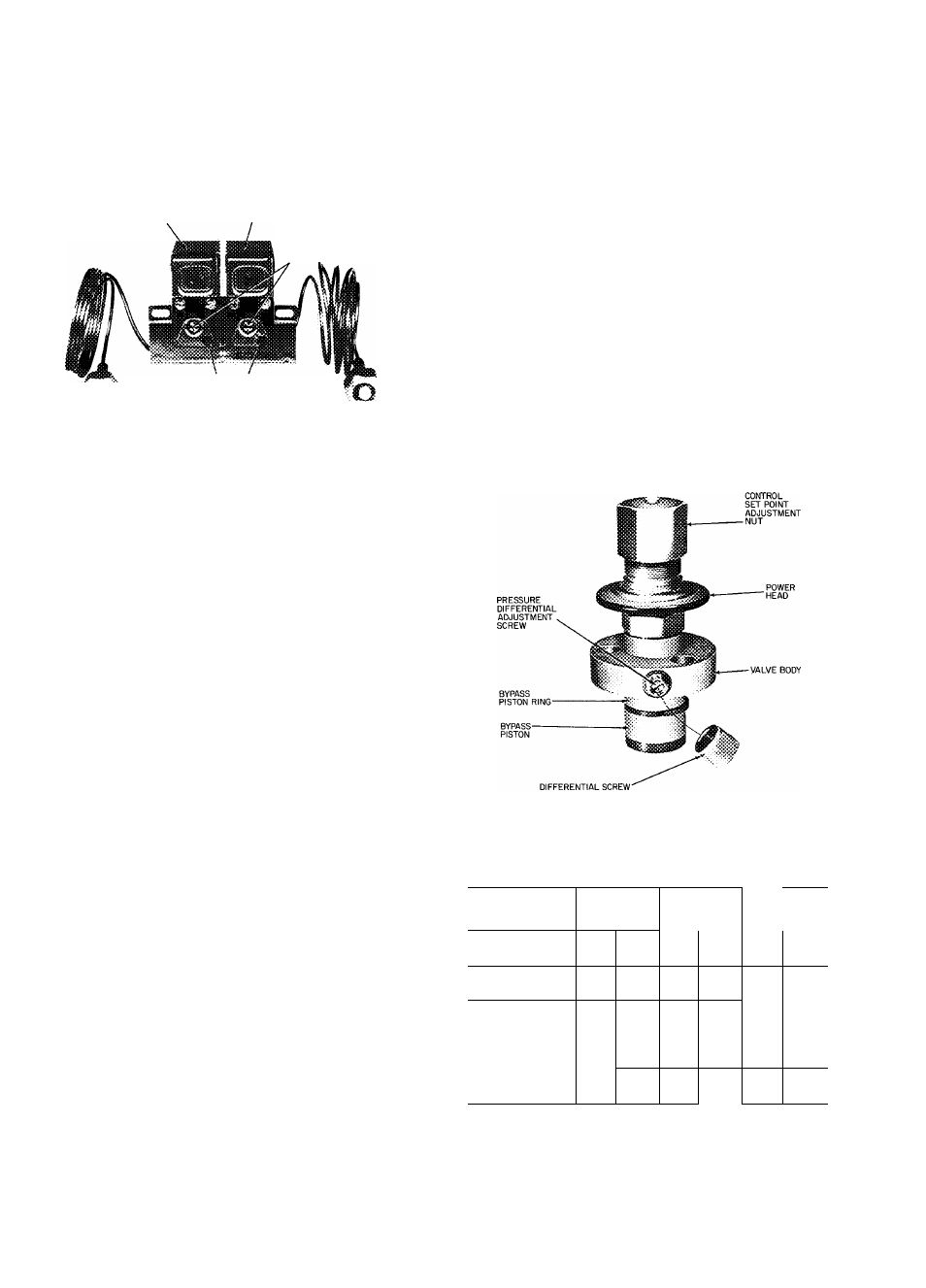

CAPACITY CONTROL ADJUSTMENT

Control Set Point

(cylinder load point) is adjust

able from 0 psig to 85 psig. Pressure differential

between cylinder load-up point and cylinder un

load point is adjustable from 6 psig to 22 psig.

To Regulate Control Set Point

— Refer to Fig. 9.

Turn adjustment nut clockwise to its bottom stop

(with nut in this position set point is 85 psig).

Control set point is then regulated to desired

pressure by turning adjustment nut counterclock

wise; every full turn decreasing set point by 7.5 psig.

(Approximately 11-1/2 turns in counterclockwise

direction will decrease control set point to 0 psig.)

Table 3 shows the steps of control for the

compressor and condensing unit.

SEALING CAP

(CAP MUST BE REPLACED

TO PREVENT REFRIGERANT LEAKAGE)

Fig. 9 — Capacity Control Valve

Table 3 — Steps of Control

COMPRESSOR*

—

1

STEPS

2

--------------- -

3

CONDENSING

UNIT*

No.

Cyl

%

Cap.

No.

Cyl

%

Cap.

No.

Cyl

%

Cap.

06EV022

07EB022

4

100

2

50

-

-

06EW027

07EB027

6

100

4

67

2

33

06EW033

07EB033

6

100

4

67

2

33

06EW044

07ED044

6

100

4

67

2

33

^Capacity control valve (Fig 6) factory settings for 4-cylinder

units are: 69 psig control set point (cylinder load point), 10 psig

differential

(59

psig

cylinder

unload

point)

Settings

for

6-cylinder units are; leit cylinder bank control set point is

70 psig, differential is 10 psig; right cylinder bank control set

point is 68 psig, differential is 10 psig