F e f – Carrier 07E User Manual

Page 10

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

f E f

o-^

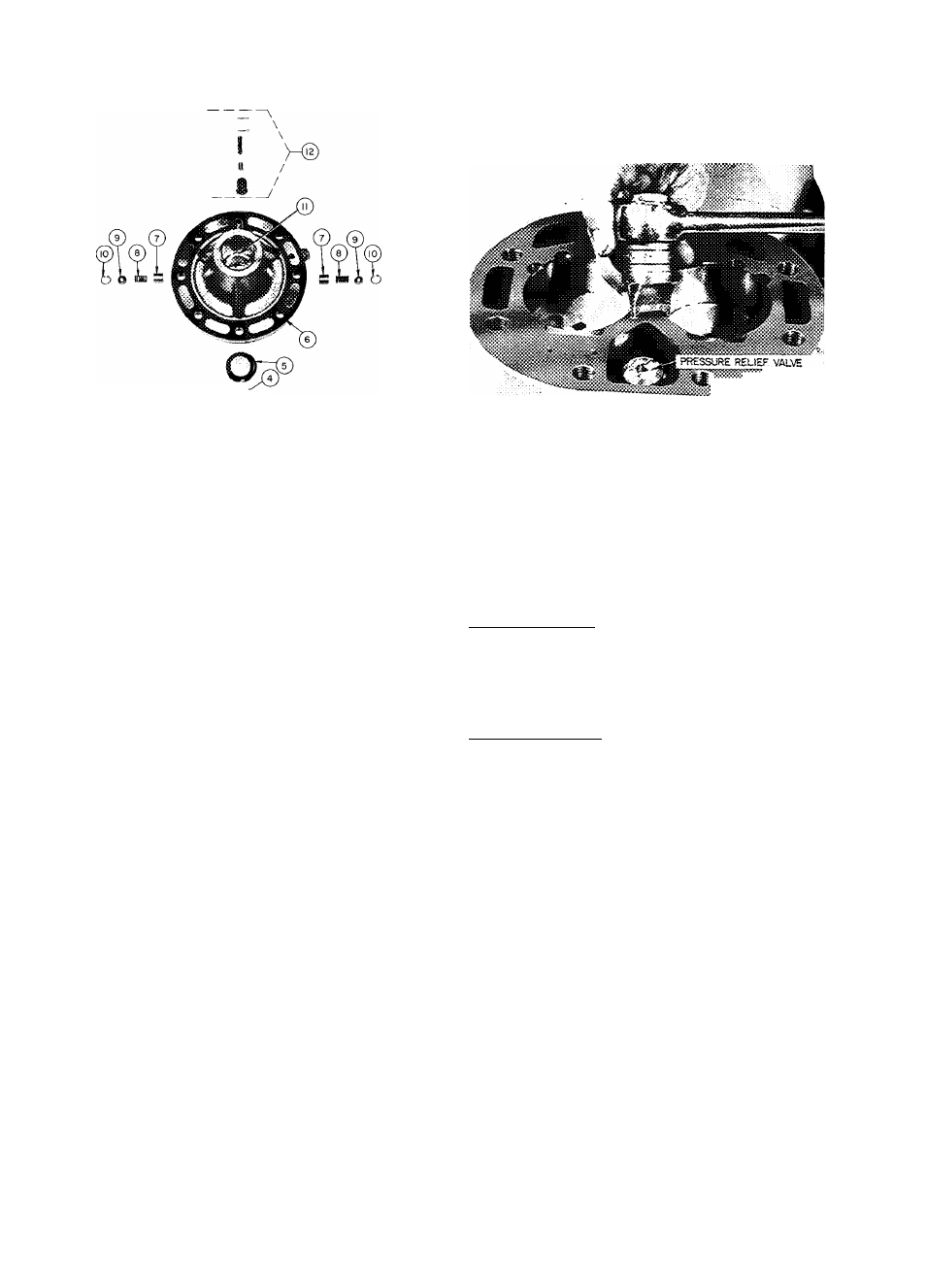

LEGEND

© Pump Vane

® Pump Vane Spring

Pump Vane Spring Guide

(i^ Retaining Spring

© Pump End Main Bearing

(12) Oil Relief Piston

o Cover Plate

Oil Feed Guide Vane Spring

® Oil Feed Guide Vane

® Drive Segment

® Pump Rotor

® Pump End Bearing Plead

Fig. 14 — Pump End Bearing Head Package

CYLINDER HEADS (Fig. 12)

Disassemble cylinder heads by removing cap

screws, and prying up on side lifting tabs to break

heads loose from valve plates. Do not hit cylinder

heads to break loose.

Check heads for warping, cracks and damage to

gasket surfaces. When replacing cylinder head,

torque cap screws 100 to 120 ft-lb (prevents high

to low side leak in center portion of cylinder head

gasket).

Pressure Relief Valve

— This safety device is

located

in

center

cyhnder

bank

(6-cylinder

compressors, Fig. 15) or under discharge service

valve (4-cylinder compressors). The valve relieves

refrigerant pressure from high to low side at

400 psi pressure differential. Check valve for

evidence of leaking. Change if defective or if valve

has ever opened due to excessive pressure. Use a

standard socket-type screwdriver to remove and

replace valve.

Capacity Control Valve(s)

are of the snap-action

type. They are controlled by suction pressure and

actuated by discharge pressure. Each valve controls

Fig. 15 — Pressure Relief Valve Removal

2 cylinders. On start-up, controlled cylinders do

not load up until differential between suction and

discharge pressure is 10 psi (see Fig. 16).

Do not use automatic pumpdown control on

06E, 07E units equipped with unloader valves. Use

single pumpout or solenoid drop (minimum

protection) control.

CAPACITY CONTROL VALVE OPERATION

Loaded Operation — When suction pressure is

above control point, the poppet valve will close.

Discharge gas bleeds into valve chamber, the

pressure closes bypass piston and cylinder bank

loads up. Discharge gas pressure forces check valve

open, permitting gas to enter discharge manifold.

Unloaded Operation — When suction pressure

* *

drops below valve control point, the poppet valve

will open. Discharge gas bleeds from behind bypass

piston to suction manifold. Bypass piston opens,

discharge gas is recirculated back to suction mani

fold and cylinder bank is unloaded. Reduction in

discharge pressure causes check valve to close,

isolating cylinder bank from discharge manifold.

SERVICE REPLACEMENT COMPRESSORS are

* not equipped with capacity control valves. Side

bank cylinder head(s) is plugged with spring loaded

plug piston assembly(ies). Compressor will run

fully loaded with piston plug(s) in place.

Transfer original capaeity control valve(s) to

replacement compressor (ensures proper valves are

used with correct setting). Install plug piston

assembly(ies) into original compressor for sealing

purposes.

Three alien head cap screws hold capacity

control valve in place (Fig. 17). Remove screws

using a “cut down” 3/16-in. alien wrench, and pull

valve from cylinder head.

Remove same number of piston plugs from

replacement compressor as number of unloaders

supplied with original compressor. Three alien head

10