Carrier 07E User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REFRIGERANT CHARGING

Evacuate, ' Dehydrate and Leak Test

the entire

refrigerant system by methods described in Carrier

Standard Service Techniques Manual, Chapter 1,

Sections 1-6 and 1-7. Use sight glass method to

charge system. See section 1-8 of Service Tech

niques Manual for details.

CHARGE THE SYSTEM to a clear sight glass while

holding saturated condensing pressure constant at

125 F (air-cooled systems) or 105 F (water-cooled

systems). Add additional refrigerant to fill con

denser subcooler coils.

07E Condensing Units

obtained.

After clear sight glass is

until liquid refrigerant

add charge

reaches condenser liquid level test cock.

06E Compressor Units — See condenser data for

additional charge required to fill subcooler.

INITIAL START-UP

Crankcase heater should be energized a mini

mum of 24 hours before starting unit.

Check to see that oil level is 1/3 to 2/3 up on

compressor sight glass.

Open water supply valve and allow water to

reach condenser. (Turn condenser fan on when the

compressor

unit

is

applied

with

air-cooled

condenser.)

Backseat the compressor suction and discharge

shutoff valves; open liquid line valve at receiver.

Start evaporator fan or chilled water pump.

To Start Compressor,

place control center start-

stop switch in “Start” position, and push motor

protector relay start-reset button. (Time Guard

circuit will cause a short delay before compressor

starts.) If compressor does not start in a 5-minute

period, reset oil pressure safety switch and over

load relays.

Recheck oil level and check oil pressure which

should be 12-18 psig above suction pressure.

NOTE: If compressor is shut off by motor

protection relay, current overloads, oil safety

switch or if control circuit power is opened, reset

button(s) must be pushed before compressor will

restart. Do not reset safety controls more than

once before determining cause of shutdown.

CHECKING OPERATIONS

Refer to Carrier Standard Service Techniques

Manual, Chapter 2 for complete instructions on

checking electrical components.

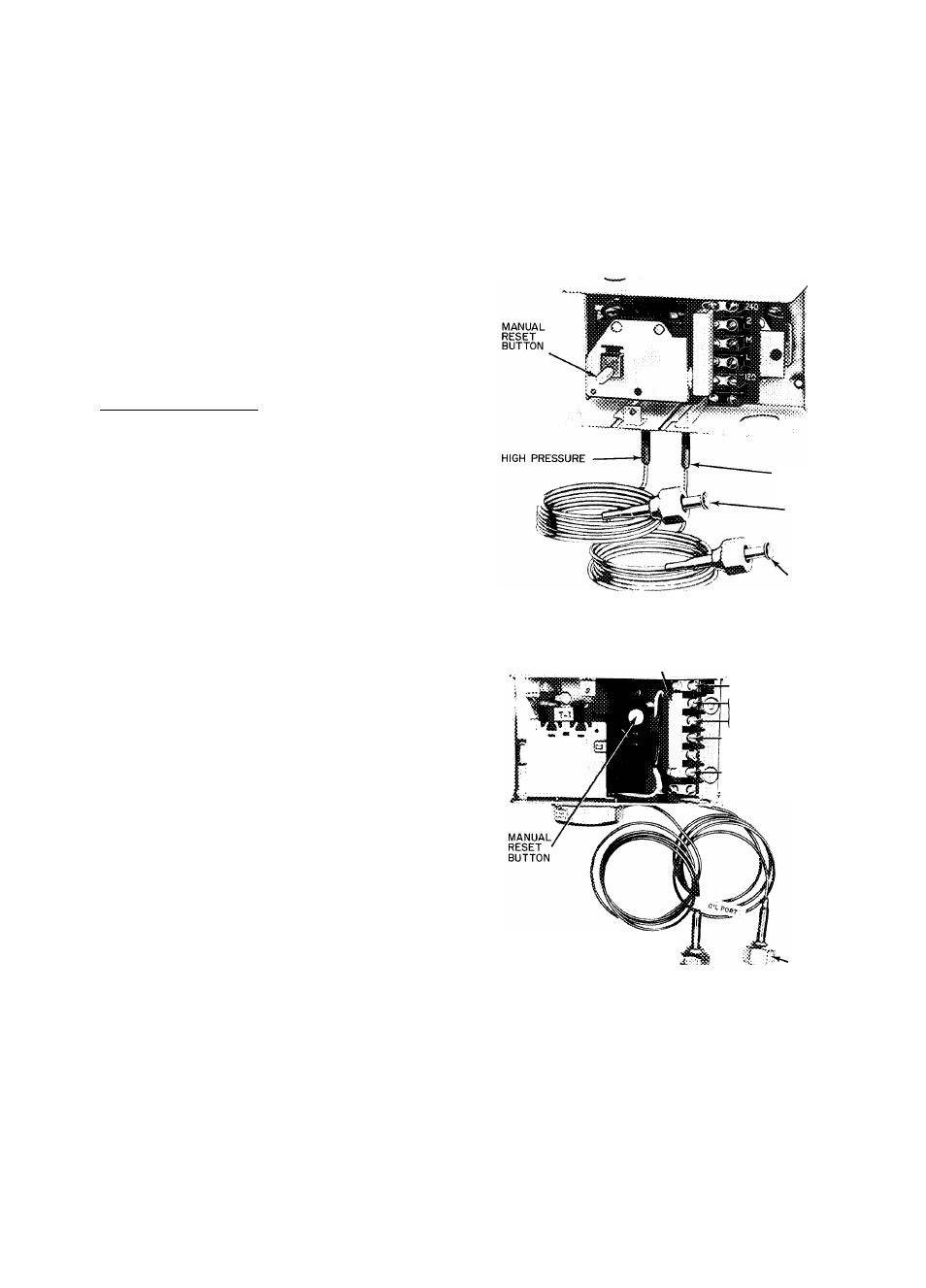

Oil Pressure Safety Switch (Fig. 6 and 7)

may be

checked by moving arm on left side of switch

forward. Compressor should stop in approximately

45 seconds. (If compressor continues to run, check

wiring to safety switch. If wiring is correct, the

switch is faulty and should be replaced.)

After completing test, press reset button on

front of safety switch and restart compressor.

(Allow 3 minutes before attempting to reset

switch.)

NOTE Check oil level in compressor sight glass

after 15-20 minutes of operation. If oil level is low,

add oil according to methods described in Carrier

Standard Service Techniques Manual, Chapter 1

(Section 1-11).

LOW PRESSURE

CONNECT TO

OIL PUMP

DISCHARGE

CONNECT TO

CRANKCASE

(Switch shown is Penn Controls )

Fig. 6 — Oil Pressure Safety Switch Used on;

06EV022, 06EW033, 07EB022, 07EB033

RESISTANCE

■f

CONNECT IN

240

SERIES WITH

VAC

CONTROL CIRCUIT I

120

V^C

(REFER TO UNIT LABEL

WIRING DIAGRAM)

HIGH-PRESSURE

CONNECTION TO

0|LPUMP

'" LOW-PRESSURE

DISCHARGE

CONNECTION

TO CRANKCASE

Fig. 7 — Oil Pressure Safety Switch Used on:

06EW027, 06EW044, 07EB027, 07ED044

Dual Pressurestat (Fig. 8)

— High-pressure safety

switch is checked by throttling condenser water or

blocking air flow on air-cooled units, allowing head

pressure to rise gradually. Check discharge pressure

constantly

throughout

procedure.

Compressor

should shut off within 10 psi of values shown in

Table 1.