Performance data (cont), Application data electrical data (60-hz), Performance data – Carrier WEATHERMASTER 38HQ User Manual

Page 6: Application data electrical data, Cont)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Performance data

(cont)

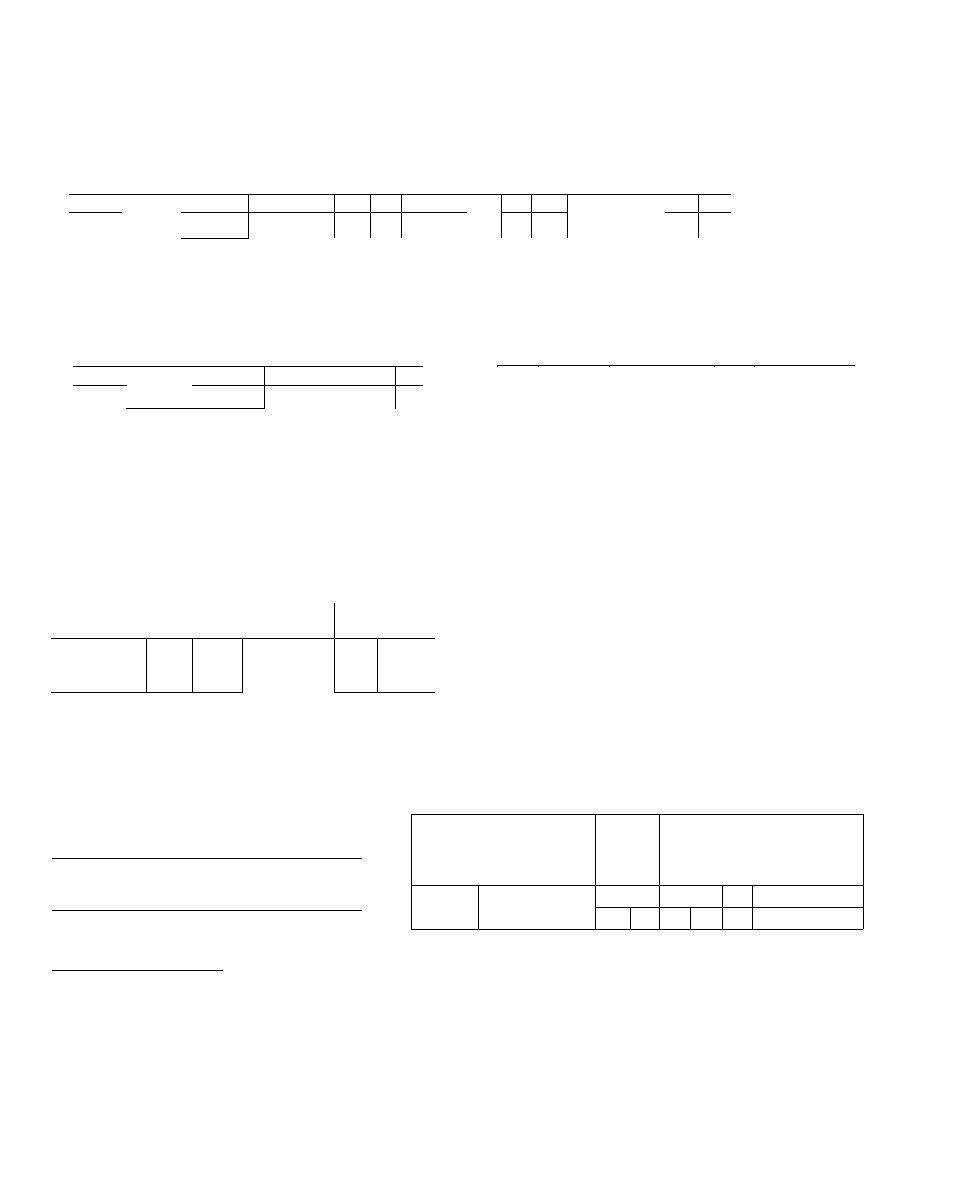

INTEGRATED HEATING CAPACITIES* (At Second Stage — both compressors operating)

INDOOR Í OUTDOOR]

COMPR

Í

COIL

I

SECTION; SgCTiON- l

зёно" 1"

INDOOR

UNIT

Fan

Coil

-13

Cap."] Kw

TEMPERATURE OF AIR ENTERING OUTDOOR COIL (Edb F)

17

Cap. ; Kw ■ Cap. ; Kw

27

Cap. : Kw ! Cap. ; Kw

32

37

42

Cap. i Kw I Cap. i Kw ; Cap. I Kw:

227

940

|40FS160

28HQ/VQ036

15 5

3 5

20 0|

3 9

24 5

4 3

29 0

4 5

34 5

5 1 1 37 0

5 3 1

234

960

140FS200

28HQ/VQ042

15 5

4 6

21 5

4 8

27 5

5 0

33 0

5 4

39 5

5 9| 42 5

6 2 I

5 7

6 9

INTEGRATED HEATING CAPACITIES* (At Eirst Stage — one compressor operating)

INDOOR I OUTDOOR]

COMPR i COIL

SECTION i SECTION*

~38Н'а

INDOOR

UNIT

Fan

Coil

TEMPERATURE OF AIR ENTERING OUTDOOR COIL (Edb F)

”27 i.............. ”32

]

37 i 42 М

М7

i 57

Cap. ' Kw : Cap. i Kw ; Cap

Kw ; Cap. : Kw ; Cap. j Kw ; Cap. ; Kw

227 1

940

1 40FS160

28HQ/VQ036 1

21 2

2 7

234 1

. J

960

1 40FS200

28HQ/VQ042 j

24 0

3 6

Cap

Kw

23 6

27 Q

Capacity (1 000 Btuh), includes fan motor heat and deduction

for thermal line losses of 1 5 ft of piping exposed to outdoor

conditions

Power input includes compressor motor power input, indoor

and outdoor fan motor input

Integrated Heating Capacities — Values shown reflect a capacity

reduction at those outdoor air temperatures at which frost forms on

outdoor coil

26 о

2 9

29 5

3 1

33 0 j

3 2

40 5

3 4

50 0 1 3 6

30 5

3 9

34 0

40

38 5

1

4 1

47 5

4 4

58 Ô 1 4 7

2 8

3 7

NOTE

Heating ratings shown in table are without accessory electric heater

and are based on 70 F db air entering indoor coil, 85% rh air entering

outdoor coil, and ARhrated cfm See Heating Capacity Correction

Factors table to calculate heating capacity and power input at other

cfm's and indoor coil entering air temperature

HEATING CAPACITY CORRECTION EACTORS

CFM/TON* ; CORRECTION ;

дщ j CORRECTION

ENT INDOOR

COIL

FACTORS

Cap, ; Power

ENT INDOOR

COIL (F)

FACTORS

Cap. i Power

400

98

99

65

1 02

99

450

1 0

1 0

70

1 0

1 0

500

1 02

1 01

75

98

1 01

‘Determine cfm/ton from Combination Rating tables

Application data Electrical data

(

60

-Hz)

INSULATION TO VAPOR LINE EXPOSED

TO OUTDOOR CONDITIONS

LENGTH OF EXPOSED

1

INSULATION

VAPOR LINE*

1

THICKNESSt

m

1 (m.)

To

1 3/8

25

1 1/2

35

! 3/4

50

1 3/4

‘Recommended vapor line insulation for piping exposed

to outdoor conditions to prevent loss of heating during

heating cycle When vapor line goes thru interior

spaces, insulation should be selected to prevent con

densation on cooling cycle Heating capacity should be

reduced 1000 Btuh if over 35 ft of vapor line with

3/4-in insulation is exposed to outdoor conditions

(Closed cell foam plastic insulation with a thermal con

ductivity of 28 Btuh/sq ft/F/inch

NOTE Vapor lines of accessory precharged tubing pack

ages (available for use with 38HQ units) are insulated

with closed cell foam plastic insulation with a thermal

conductivity of 28 Btuh/sq ft/F/inch

iNOoo? j

outdoor

]

COMPFT ] COIL 1

SECTION] SECTION {

~~~~~

38HCL

OPER

VOLT*

Max 1 M»r

' 1 ! ;

COMPR ; COMPR М

, О

- tOFM;

^ 1

2 Í i MWA

lra

I

rla

Í

lraírla

I Fui1

227

234

940

; 230/1

960

9Я4 907

72 I 17

88

17 8| 1 5 i 40 8

88

20

94

21 2 : 2 3 i 48 8

FLA — Full Load Amps

LRA — Locked Rotor Amps

MWA — Min imum Wire Amps

OFM — Outdoor Fan Motor

RLA — Rated Load Amps

‘Permissible limits of the voltage range at which the units will operate satisfactorily

NOTES

1 All units have 24-v control circuit which requires external power source

2

Use copper or copper-clad aluminum wire only for compressor section; copper

wire only for outdoor coil section See Installation, Start-Up and Service

Instructions

3

Units require field-supplied grounding wire See Installation, Start-Up and

Service Instructions for wire sizes