Step 5 — make electrical connections – Carrier 38AQ034 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

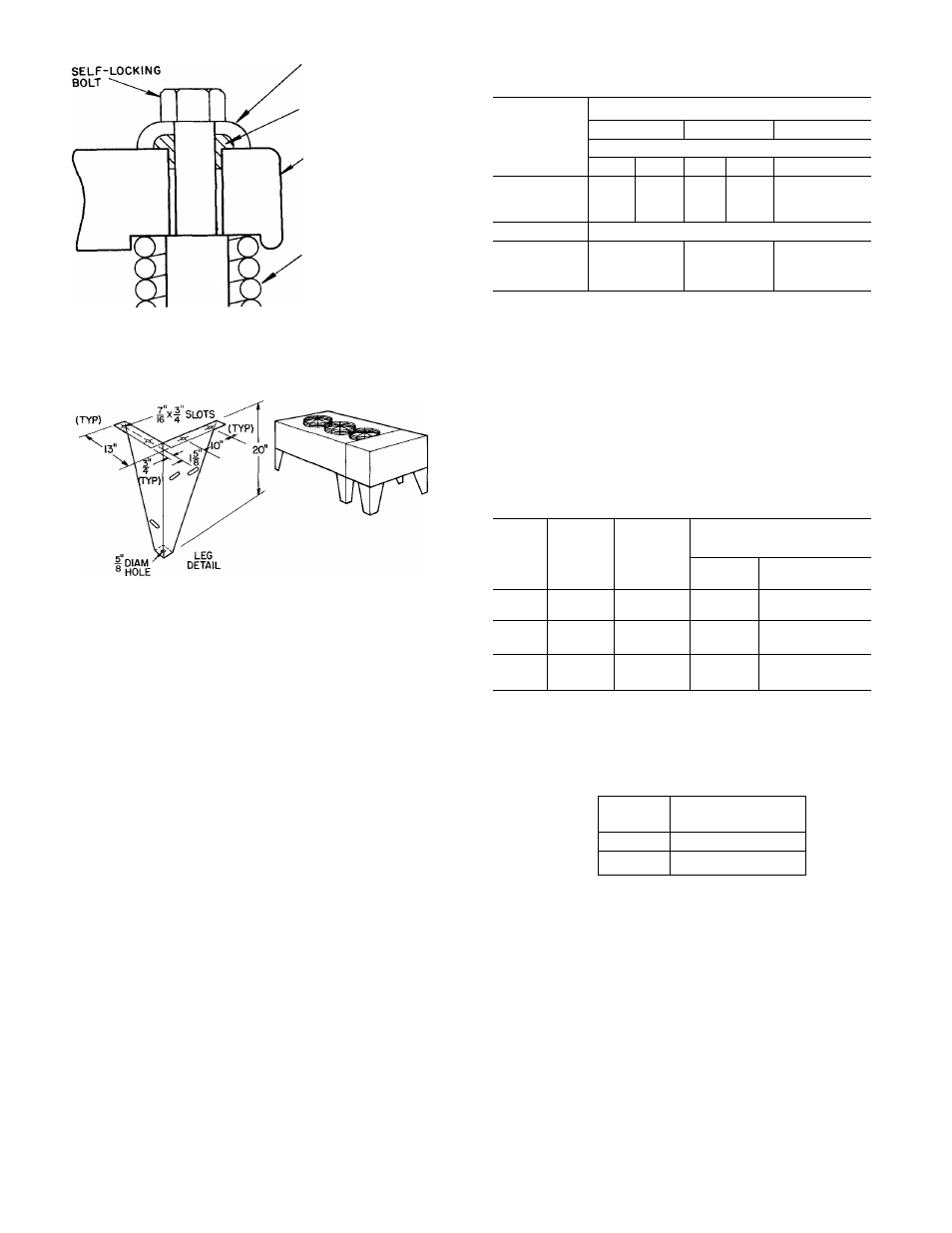

SNUBBER

FLANGED

WASHER

.

neoprene

SNUBBER

Table 3 — Refrigerant (R-22) Charge and

Piping Selection Data

ISOLATION SPRING

Fig. 4 ~ Compressor Mounting

NOTES

1 For mounting dimensions, see Fig 1.

2 Parts package contains all fasteners required for assem

bling 20-in. legs to unit

Fig. 5 — Mounting Legs for 38AQ Units

Step 5 — Make Electrical Connections

POWER

SUPPLY

—

Electrical

characteristics

of

avail

able

power

supply

must

agree

with

nameplate

rating.

Supply

voltage

must

be

within

tolerances

shown

in

Tableó.

See

Fig.

6

for

System

Label

Diagram.

Phase

unbalance

must

not

exceed

2%.

Operation

of

unit

on

improper

supply

voltage

or

with

excessive

phase

un

balance constitutes abuse and is not covered by Carrier

Warranty.

POWER

WIRING

—

All

power

wiring

must

comply

with

applicable

local

requirements

and

National

Elec

trical Codes. Install a field-supplied branch circuit dis

connect switch of a type that can be locked OFF or

OPEN. Run power wires from disconnect switch through

unit power opening (D on Fig 1 ) and connect to terminal

block

just

inside

opening.

See

Table

5

for

maximum

allowable wire size.

Power terminal block is in the control box. Remove

outer panel and #10 screw on the door. Swing door open,

remove screws on barrier panel and remove barrier panel.

Replace barrier panel when power wiring is completed.

Condenser

fans

must

rotate

clockwise

when

viewed

from above. If necessary, correct direction of fan rotation

by reversing any 2 power input wires at disconnect switch.

Affix crankcase heater decal to unit disconnect switch.

CONTROL

CIRCUIT

WIRING

—

Internal

control

voltage on 38 AQ units is both 115-volts and 24-volts. All

control circuit wiring must comply with applicable local

LENGTH OF PIPING (ft)*

OUTDOOR

0-25

26-60

61-100t

UNIT

38AQ

Line Size (in. O.D.)

L

V

L

V

L V

024

%

1%

%

1%

% 1 %

028

%

1%

%

1%

V

b

2 Va

034

%

U/s

%

2'/8

%

2'/8

Approximate System Charge (lb)t

024

55

58

75

028

61

65

83

034

71

79

93

L

— Liquid Line

V

— Vapor Line

'Approximately 4 elbows assumed in determining pipe sizes

fMaximum length of interconnecting piping is 100 feet.

^Approximate system charge is for estimating only It includes

charge requirements for one outdoor unit, matching indoor coil,

and interconnecting piping System should be charged in

accordance with installation instructions

NOTE Maximum liquid line size is %-in OD Maximum R-22

system charge is 85 lb (024), 95 lb (028), 105 lb (034)

Table 4 — Minimum Outdoor Air Operating

Temperature

MINIMUM OUTDOOR

UNIT

COMPR

CONO

TEMPERATURE (F)*

38AQ

CAP. (%)

TEMP (F)

Std Unit

32LT

Motormaster®

024

100

90

28

-20

50

80

41

-20

028

100

90

34

-20

67

80

37

-20

034

100

90

30

-20

67

80

33

-20

'Applies to cooling mode of operation only

Table 5 — Maximum Allowable Field Wire Sizes

UNIT

38Aa

024,028,034

VOLTS

(60-Hz)

WIRE SIZE

208/230

6 AWG to 350 MCM

460, 575

14 AWG to 2/0

CONN.

TB

TB

Terminal Block (with integral compression terminal)

and national codes. Route remote control wiring to unit

control box through control opening (C on Fig. 1) and

connect to control terminal block inside the control box.

All external control wiring is 24-volt, NEC Class 2.

SAIL

SWITCH

—

It

is

highly

recommended

that

an

indoor

airflow

switch

(field

installed)

be

installed

and

interlocked with the outdoor unit, to prevent the outdoor

unit from operating in the event of indoor airflow failure

(example: broken fan belt). Operation of compressor with

no

indoor

airflow

causes

compressor

to

operate

in

a

vacuum

which

can

damage

bearing

surfaces.

Therefore,

install a field-supplied sail switch in the supply air duct

work of the mating indoor fan coil unit, and wire to

outdoor unit. See Fig 7.

.4^