Fig. 12 — typical heat pump operation – Carrier 38AQ034 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

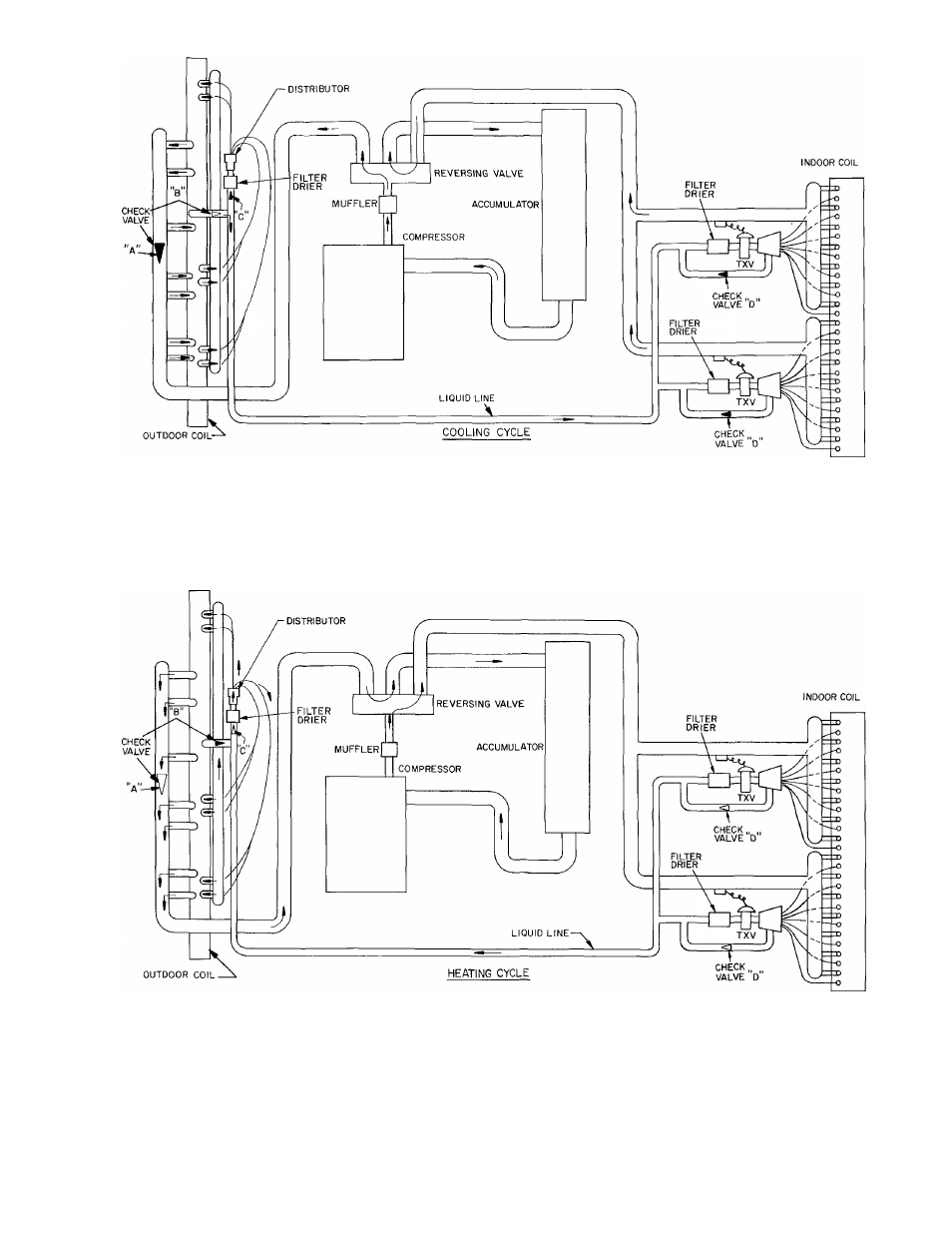

Hot gas from compressor flows through the 4-way valve and is

directed to the outdoor coil header At the header it is con

densed and subcooled through converging circuits Refrig

erant leaves the outdoor coil by way of the check valve to the

liquid line

The refrigerant then fiows through the filter drier and feeds the

indoor coil by way of capillary tubes on each circuit

3 Each circuit evaporates the refrigerant and the circuits are

combined in the indoor coil header

4 The refrigerant then flows through the 4-way valve, accu

mulator and back to the compressor.

Hot gas from compressor flows through the 4-way valve and is

directed to the indoor coii header At the header it is con

densed and directed through subcooling circuits and out the

indoor coil check valve to the liquid iine. (The TXV’s stop

the refrigerant fiow during the heating cycle )

The refrigerant then feeds the outdoor coil by way of a strainer

and then through capiliary tubes on each circuit

Each circuit evaporates the refrigerant and the circuits are

combined in the outdoor header with some of the circuits

flowing through the check valve

The refrigerant then flows through the 4-way valve, accu

mulator and back to the compressor

NOTES:

1 Check valves are designated “A” through “D ”

2. Illustrations are typicai and do not portray exact coil circuiting

3 Check valve positions:

A

open,

A

closed.

4 Only one outdoor coil is shown above The 38AQ024,028 and

034 have 2 coils plus 2 of each check valve shown above

Fig. 12 — Typical Heat Pump Operation

11