Charge machine with oil, Final preoperation alignment check, Operate drive – Carrier 17DA User Manual

Page 5: Set purge valves and switches, Check water supply, Check air supply, pneumatic machines, Start-up

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

or gear to check for alignment drift while charging

with water and refrigerant. The weight of these

materials will always cause a shift in the position of

the machine components. Before and after indi

cator readings will give a good clue to the direction

final alignment should take.

CHARGE MACHINE WITH OIL

The 17DA machine has an integral lubrication

system mounted on the common base with the

compressor. A parallel auxiliary oil pump system

may also be furnished. Charge the oil system with

35 gal. of oil per Carrier Specification PP16-0

(Table 4). If oil other than this is used, the

replacement oil must be nearly equivalent.

Ensure that there is adequate lubrication prior

to the operation of all equipment. Check the gear

and drive manufacturer’s instructions for proper

initial

lubrication

procedure.

If

the

drive

machinery is to be operated before operating the

compressor, disconnect the shaft coupling and'

secure the shroud to prevent damage to the drive

shaft or the coupling.

Oil pressure from the main oil pump is set at a

pressure 35 psi greater than the back-of-seal oil

pressure. If, for any reason, the oil pressure falls to

23 psi above the back-of-seal oil pressure, the

auxiliary oil pump starts and maintains oil pressure

at a safe level.

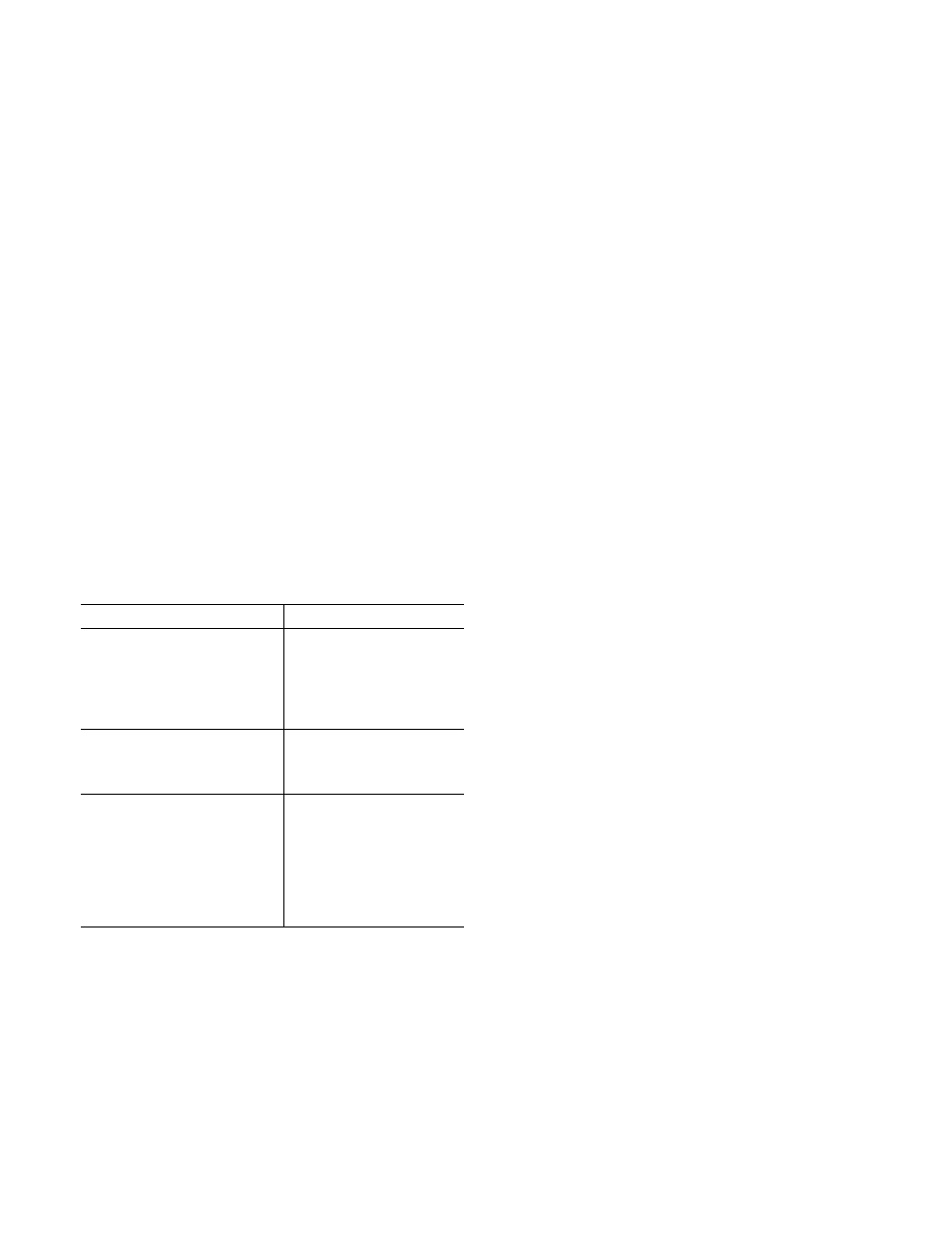

Table 4 — Oil Specification (Carrier PP16-0)

CHARACTERISTIC

VALUE

Viscosity at 100 F

150 - 160 SSU

Viscosity at 210 F

40 - 45 SSU

Viscosity Index, minimum

90

Pour Point, maximum

0 F

Flash Point, minimum

400 F

Neut. No., maximum

.1 mg. KOFl/gm.

Rust Inhibiting Characteristics

Thematerial shall passthe

ASTM Rust Test D665-54.

Procedure A will be used

with a test period of24hr.

Oxidation Resistance

Thematerial shall passthe

ASTM Oxidation Test

D943-54 for a minimum of

1500 hr. The acid number

at the end of the test

period shall not exceed

2.0 mg. of KOH per gram

of oil.

SSU

— Saybolt Seconds Universal

FINAL PREOPERATION ALIGNMENT CHECK

Prior to operating the compressor and speed

increasing gear (if used), coupling alignment and

separation must be checked.

1.

Ensure that coupling alignment is within

coupling manufacturer’s specified tolerances.

2.

The hub separation tolerances are normally

stamped on coupling and vary depending on

coupling size.

3. When checking hub separation, electric motor

shaft must be in center position of shaft float.

If realignment is required, follow instructions

supplied by coupling manufacturer. Carrier Standard

Service Techniques, Form SM-15, Rev A, also de

tails realignment techniques.

OPERATE DRIVE

It is good practice to operate the drive sep

arately before operating compressor. Refer to drive

manufacturer’s instructions for drive protection

devices and settings. Check turbine overspeed at

this time. Reassemble couplings after operating

drive separately.

SET PURGE VALVES AND SWITCHES

Open all the purge service valves behind purge

console. Place purge operating valves in NORMAL-

AUTOMATIC position (shown on chart inside

console door). Place purge switch in AUTO,

position.

CHECK WATER SUPPLY

Be certain that chilled water, condensing water

and oil cooler water supplies are available and that

pumps will run before operating compressor.

CHECK AIR SUPPLY, PNEUMATIC MACHINES

Make sure that control air is 35 psig.

START-UP

Preoperation Settings

— Complete these settings

before starting compressor for first time.

Drive Operation

— Refer to drive manufacturer’s

start-up

instructions.

Complete

drive

starting

requirements before operating compressor.

If drive is wired for automatic starting, it will

start when compressor START button is pushed.

Starting procedure of manually started drives may

be initiated after START button is pushed.

Compressor Operation

1. Place control switch in ON position. Con

denser pressure, bearing temperature and

refrigerant temperature indicating lights on

control console should come on.

2. Place capacity control switch in MANUAL

position.

3. Open oil cooler water plug cock. Check fqr

water flow at open sight drain.

4. Open bleed valve on inboard side of the

compressor.

5. Open all valves and energize heater on seal oil

drain pot.

6. Open all valves in chilled water and condenser

water circuits.