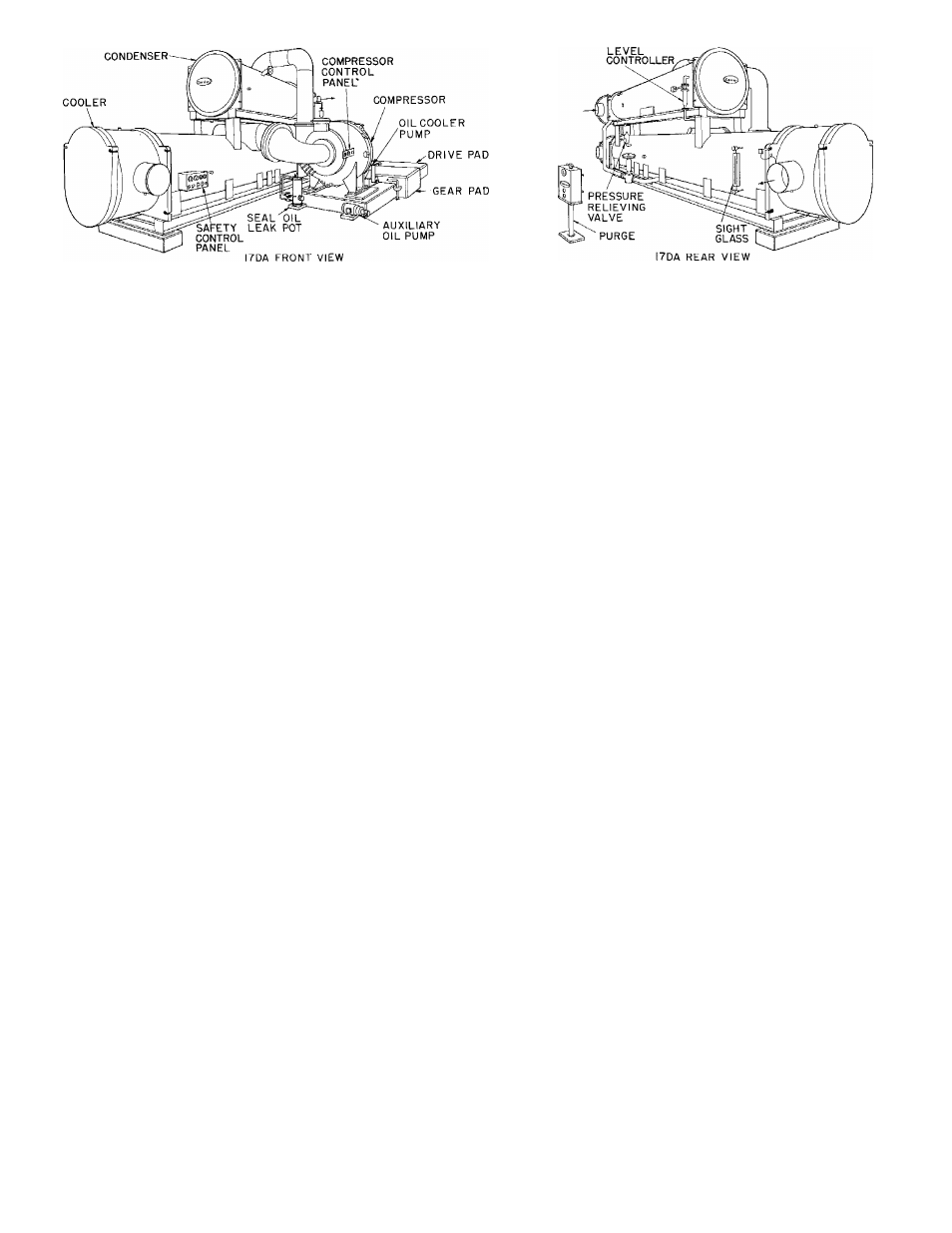

Carrier 17DA User Manual

Page 2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CONTENTS

PAGE

General

2

Factory Test

2

Job Data

2

Essential Tools

3

Machine Room

3

Drive Arrangement

3

Piping

3

Wiring

3

Auxiliary Equipment Wiring

3

Turbine Drive Wiring

3

Gas Engine Drive Wiring

3

Safety Controls

3

Motor Drive

4

Turbine or Gas Engine Drive

4

Pumpout System

4

FINAL PREOPERATION ALIGNMENT

CHECK

5

CHECK AIR SUPPLY, PNEUMATIC

MACHINES

5

START-UP

5

Preoperation Settings

5

Drive Operation

5

Compressor Operation

5

HOT ALIGNMENT CHECK AND

DOWELING

7

INTRODUCTION

General

— All persons concerned with the start-up

and operation of the centrifugal refrigeration

machine should be familiar with the equipment

involved. This instruction book is intended to

cover general rules for start-up procedures.

Because of machine variations it is not possible

to prepare an instruction book covering all minor

details. This instruction book will fulfill normal

requirements. Additional information may be ob

tained by application to Carrier Machinery and

Systems Division Service Supervisor in the nearest

district office.

Special attention should be given to precaution

ary instructions emphasized in this book to avoid

start-up difficulties. These precautions are, in

general, applicable to all sizes of 17DA centrifugal

refrigeration machines.

Instructions for the prime mover if not in

cluded with Carrier Air Conditioning instructions

should be obtained from the manufacturer.

Factory Test

— Prior to shipment, the compressor

is completely assembled and tested. Performance as

to lubrication, speed balance and general mechani

cal

operation

has

been

determined

to

be

satisfactory.

Job Data

— consists of:

1. 17DA Start-Up Instructions

2. Blueprints showing:

a. Machine assembly

b. Machine wiring

c. Machine piping

d. Special controls, if any, and related wiring

3. 17DA Installation Instructions

4. 17DA Operation and Maintenance Instructions

%

5 . Manufacturer’s Installation and Start-Up In

structions for:

a. Drive

b. Gear (if applicable)