Inspect and adjust – Carrier 17DA User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

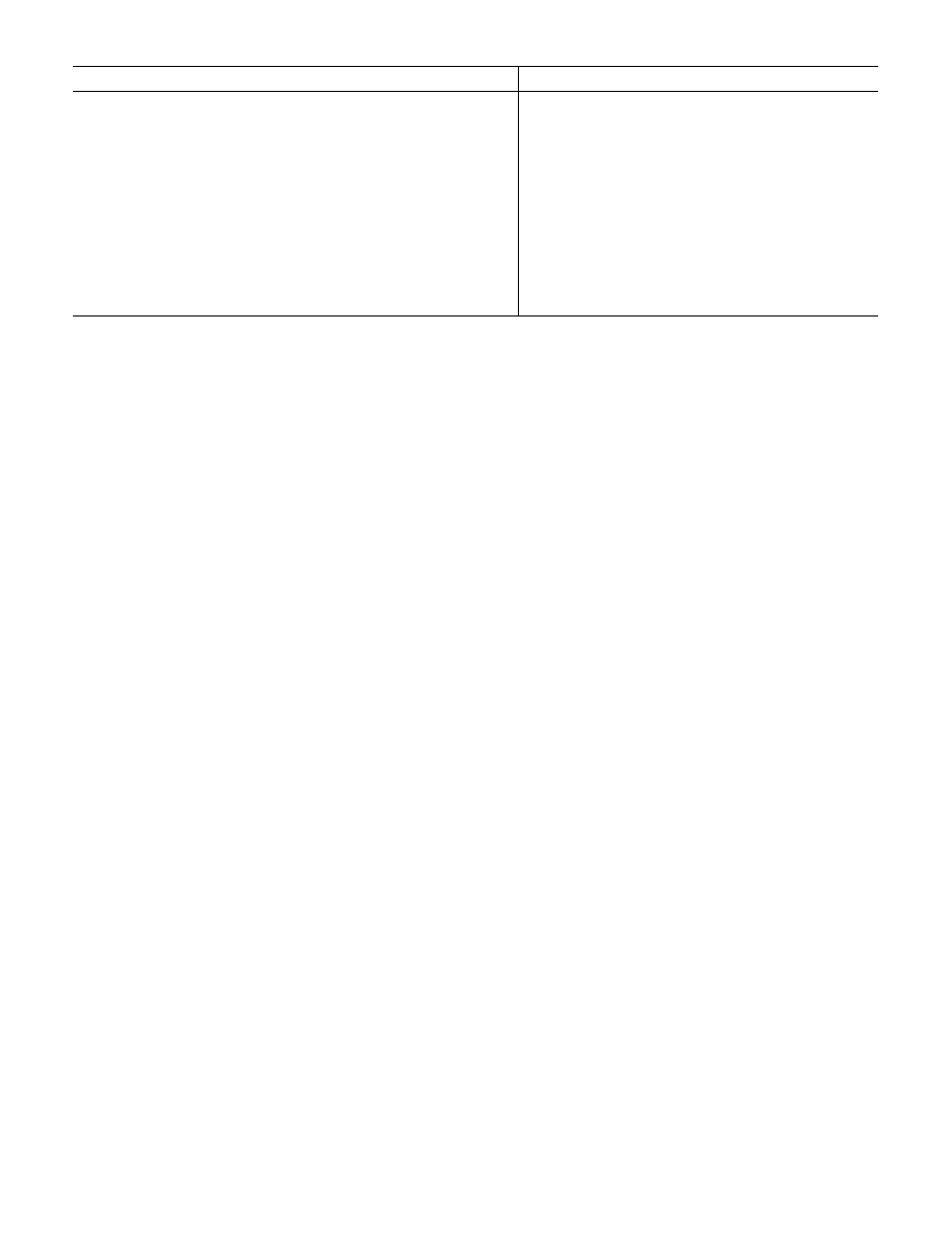

Table 1 — Essential Tools

ITEM

USE

1. Mechanic's tools

1. Machine piping connections, control calibration

2. Día! indicators

2. Check alignment

3. Volt-ohmmeter

3. Calibrate controls

4. Drum charging valve

4, Refrigerant charging connection

5. 5/8-inch SAE X 3/4-inch MPT adopter

5. Cooler charging valve

6. 5 to 10 ft length of 5/8-lnch soft copper tubing with 5/8-inch

6. Charging line

flare nut on each end

7. Halide leak detector or electronic leak detector'

7. Leak testing machine

8. Low-pressure indicator such as:

8. Check machine dehydration

a. Absolute pressure manometer or

b. Vacuum indicator

9. Portable dehydration vacuum pump — 5 or 7.5 cfm capacity

9. Dehydrating machine

10. 1/2-inch flare plug

10. Block purge suction line during leak testing

Essential Tools

— See Table 1 for tools and

materials required to perform initial start-up.

INSPECT AND ADJUST

Machine Room

— All installation work as outlined

in 17DA Installation Instructions book should be

completed, and all construction debris must be

removed

from

the

immediate

area

of

the

machinery prior to initial start-up of the machine.

Drive Arrangement

— Inspect drive mounting,

location, couphng, speed rating, etc., for agreement

with job blueprints and specifications. Gear assem

bly (if used) must agree with installation recom

mendations

outlined

in

gear

manufacturer’s

instructions.

Piping

— Check the following installations:

1. Refrigerant pumpout system

2. External or auxiliary oil system

3. All bypass lines and valves

4. Turbine drive piping, i.e.

a.

Blowdown valves for each turbine stage

installed per manufacturer’s instructions.

b.

Oil lubrication piping for speed control

installed in agreement with blueprints.

c. Steam supply Une condensate traps properly

installed to keep condensate out of turbine.

d. Proper supports on steam supply and ex

haust line to prevent stress or strain on the

turbine at operating temperatures.

5. Gas engine drive piping — Check the following

piping for agreement with job blueprints:

a. Gas pressure reducing valves with shutoff

valves.

Engine coolant piping with coolant thermo

static valve installed so that water flows in

direction marked on valve.

Oil cooler package piping

Exhaust piping

WARNING: Exhaust piping is critical.

Refer to drive manufacturer’srecominen-

dations for installation of exhaust piping.

b.

c.

d.

Wiring

— Refer to job wiring blueprints. All wiring

must agree with these prints.

AUXILIARY EQUIPMENT WIRING - Check the

following:

1. Brine pump

2. Condenser water pump

3. CooHng tower fan motor

4. Auxiliary oil pump

5. Oil heater

6. Overload selections in all motor starters. Over

load values must agree with motor nameplate

data.

TURBINE

DRIVE

WIRING

-

Check

the

following:

1. Turbine solenoid trip mechanism.

Auxiliary oil pump if used. Check pump starter

for proper voltage, amperage, and overload

setting. Operate pump to determine direction

of rotation. Do not operate dry of oil.

Check job drawings for other electrical devices

used with the turbine. Ensure that their wiring

agrees with the job wiring blueprints.

GAS ENGINE DRIVE WIRING - All wiring must

agree with job wiring blueprints. Refer to engine

manufacturer’s instructions for starting techniques.

Safety Controls

— It is good machinery practice to

preset safety controls using standard temperature

sources; i.e., ice baths, warm circulating oil baths

with standard calibrated thermometers. All con

trols must be rechecked during machine operation

and given final calibration as required. See Table 2

Control Settings and Fig. 1 17DA Safety Instru

ment Panel.

Check the following safety controls as shown

on job blueprints:

1. Main drive de-energizing devices, i.e.

a. Starter holding coil

b. Turbine solenoid trip, etc.

2. Brine low-temperature cutout

3. Refrigerant low-pressure cutout

2

.

3.