Leak test and dehydration, Charge machine with water – Carrier 17DA User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 2 — Control Settings

CONTROL

LOCATION

SETTING

British Values

Metric Values

Low Chilled Water Temperature

Cutout

Cooler Water Box

38 F or 5 F lower than brine

temperature

1.7 C

High Discharge Gas Temperature Cutout

Compressor End Wall

240 F

115 C

High Thrust Bearing Temperature

Compressor Bearing Chamber 180 F

82.5 C

High Condenser Pressure Cutout

Control Panel

165 psig

11.6 kg/sq cm

Low Cooler Pressure Cutout

Control Panel

Vendor set at 35 psig. Reset 2 psi

below normal suction pressure.

2.45 kg/sq cm

. 14 kg/sq cm

Low Seal Oil Pressure Cutout

Control Pane!

Open 11 psid

Close 16 psid

.76 kg/sq cm

1.16 kg/sq cm

Low Bearing Oil Pressure Cutout

Control Panel

Open 8 psig

Close 13 psig

.56 kg/sq cm

.90 kg/sq cm

Auxiliary Oil Pump

Differential Pressure

Control Switch

Control Panel

Open 27 psid

Close 23 psid

1.90 kg/sq cm

1.60 kg/sq cm

4.

5.

6

.

Oil low-pressure switches

Condenser high-pressure cutout

Check the following optional safety devices:

a. Brine flow switch

Condenser water flow switch

Condenser refrigerant level switch

Drive protection devices

Pump interlocks

Special interlocks, timers, etc.

b.

c.

d.

e.

f.

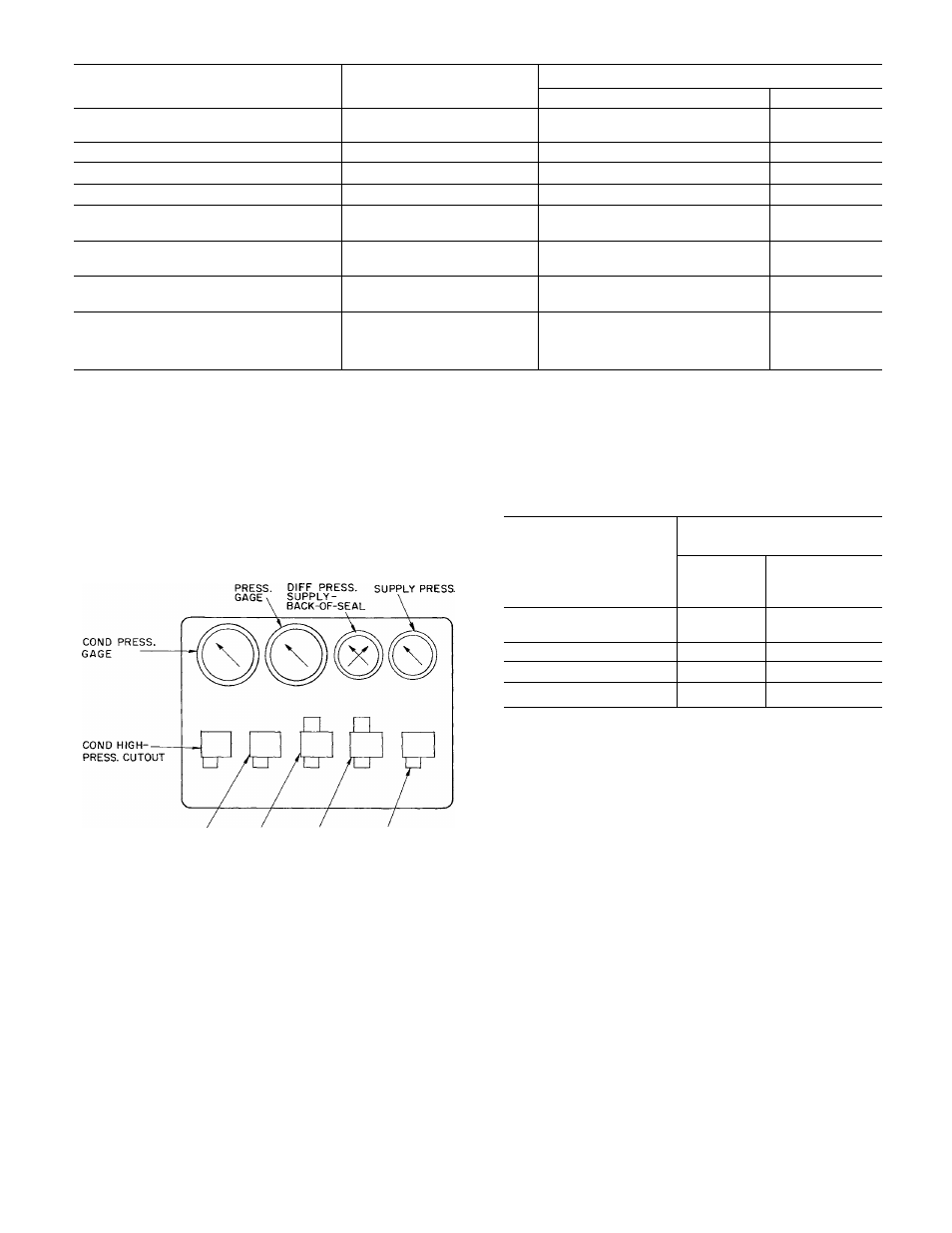

COOLER SEAL OIL

BEARING OIL

COOLER AUXOIL LOW SEAL LOW BEARING

LOW-PRESS. PUMP OIL PRESS. OIL PRESS.

CUTOUT CONTROL CUTOUT CUTOUT

Fig. 1 — 17DA Safety Instrument Panel

MOTOR DRIVE — Disconnect the main motor

leads at the starter to check out the safety controls

without operating the motor. Disconnecting the

leads to the starter holding coil will accomplish the

same purpose. Place a volt-ohmmeter across the

open leads. The volt-ohmmeter will indicate when

the safety control circuit is de-energized as each

safety control is tripped.

TURBINE OR GAS ENGINE DRIVE - These

drives are shut down by interruption of power to

their respective control valves or other devices.

Apply a volt-ohmmeter across these open leads and

check out all safety controls as just described.

PUMPOUT SYSTEM — The low-pressure cutout

should be set at the saturated pressure of

Refrigerant-12 at 34 F. A manual bypass switch is

required to allow complete evacuation of the

cooler. See Table 3.

Table 3 — Pumpout System Settings

PUMPOUT

SATURATED CONDITIONS

REFRIGERANT 12

SYSTEM

SETTING

Pressure

(psig)

Maximum

T emperature

(F)

Normal Condensing

Pressure

136.4

no

Low-Pressure Cutout

31.5

34

High-Pressure Cutout

157.7

120

Relief Valve

181.0

130

LEAK TEST AND DEHYDRATION

Check the absolute pressure on the refrigerant

side of the machine. The final operation of the

17DA Installation Instruction is to leak test the

machine and dehydrate it to the point where it

maintains a pressure of 0.21 psia (equivalent to

29.48 in. mercury vacuum referenced to a 30 in.

barometer). Refer to Carrier Standard Service Tech

niques, Form SM-1.

If the machine absolute pressure is higher than

the above values, repeat the Evacuation and De

hydration pumpdown operations until the machine

proves to have a leak rate or vacuum loss at a rate

less than 0.1 in. mercury column in 24 hr.

CHARGE MACHINE WITH WATER

When the machine has been proved leak tight

and dry, it may be filled with water, brine or other

process fluid as the case may be. Vent aU lines and

check for leaks.

It is advisable to install indicators on the

coupling halves between the compressor and drive