Carrier 58DE User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

n

#

the wires pass from the thermostat should, be adequately

sealed with suitable material to prevent drafts" from affect

ing the thermostat.

VI. SEQUENCE OF OPERATION

A. Heating (See Figure 8)

When the thermostat calls for heat, power from the trans

former simultaneously energizes the pilot gas valve (inside

of main gas valve), spark igniter, and heat-assist coil in the

fan switch.

When the pilot flame is established, the flame sensing probe

acts to energize the main gas valve, permitting gas flow to

the burners. The electrode will continue to spark for approx

imately 5 to 10 seconds after pilot flame is established. The

blower motor will be energized through the fan switch by

means of the heat assist and temperature rise in the heat ex

changer.

When the thermostat is satisfied, the circuit between R and

W is broken, deenergizing the pilot gas valve, and stopping

gas flow to both pilot and main burners. The main gas valve

also closes. When the fan switch opens its contacts, the

blower motor stops.

If the furnace overheats for any reason, the limit switch

opens, breaking the circuit to the pilot valve coil, closing the

pilot valve, and stopping gas flow to pilot and main burners.

The pilot and main burners continue to cycle until the fault

is corrected.

If there is a motor failure, clogged filters, blocked outlets,

etc, heat will build up in the blower compartment. The aux

iliary limit senses heat in the blower compartment and its

contacts open, breaking the circuit to the low-voltage con

trols. The auxiliary limit is a manual reset and will require

resetting before power can be restored to the low-voltage

controls.

B. Automatic Gas Control Valve

When the thermostat “calls for heat,” the pilot valve opens,

permitting gas flow to the pilot. When a pilot flame is estab

lished, the sensing probe permits energizing of the automat

ic main gas valve. Gas then flows to the main burners where

it is ignited by the pilot flanje. . ,

^

Tb shut off the gas manually: Turn knob from ON to OFF

position. When in OFF position, the main burners and the

pilot flame are extinguished.

C. Spark Ignition Pilot

Each furnace is equipped with a fully automatic spark-

ignited pilot. When the thermostat “calls for heat,” the

igniter is energized, sending a high-voltage charge to the

electrode located at the pilot. After a pilot flame is estab

lished, sparking will continue for 5 to 10 seconds, and the

flame sensing probe permits the main gas valve to open.

D. Fan/Limit Control Operation

At the moment the main gas valve opens, the time-delay

mechanism of the control is energized. If, due to pilot out

age, the control bimetal element does not sense a tempera

ture change, the control will turn on the blower strictly by

means of the time-delay feature. If for any reason the time

delay is not energized, the control bimetal element will

bring on the blower when it senses a temperature rise of 70

degrees Fahrenheit (standard differential) above the turnoff

setting. During the blow-down period and after the ther

mostat is satisfied, the control will turn the blower off at the

indicated setting sensed by the control bimetal element.

E. Cooling

When the thermostat “calls for cooling,” power from the

transformer energizes the blower relay coil, closing its con

tacts, and energizing the blower motor on its cooling speed.

It continues to operate until the thermostat is satisfied.

When the thermostat is satisfied, the circuit to terminal (G)

is broken, deenergizing the blower relay coil which, in turn,

opens its contacts, stopping the blower motor.

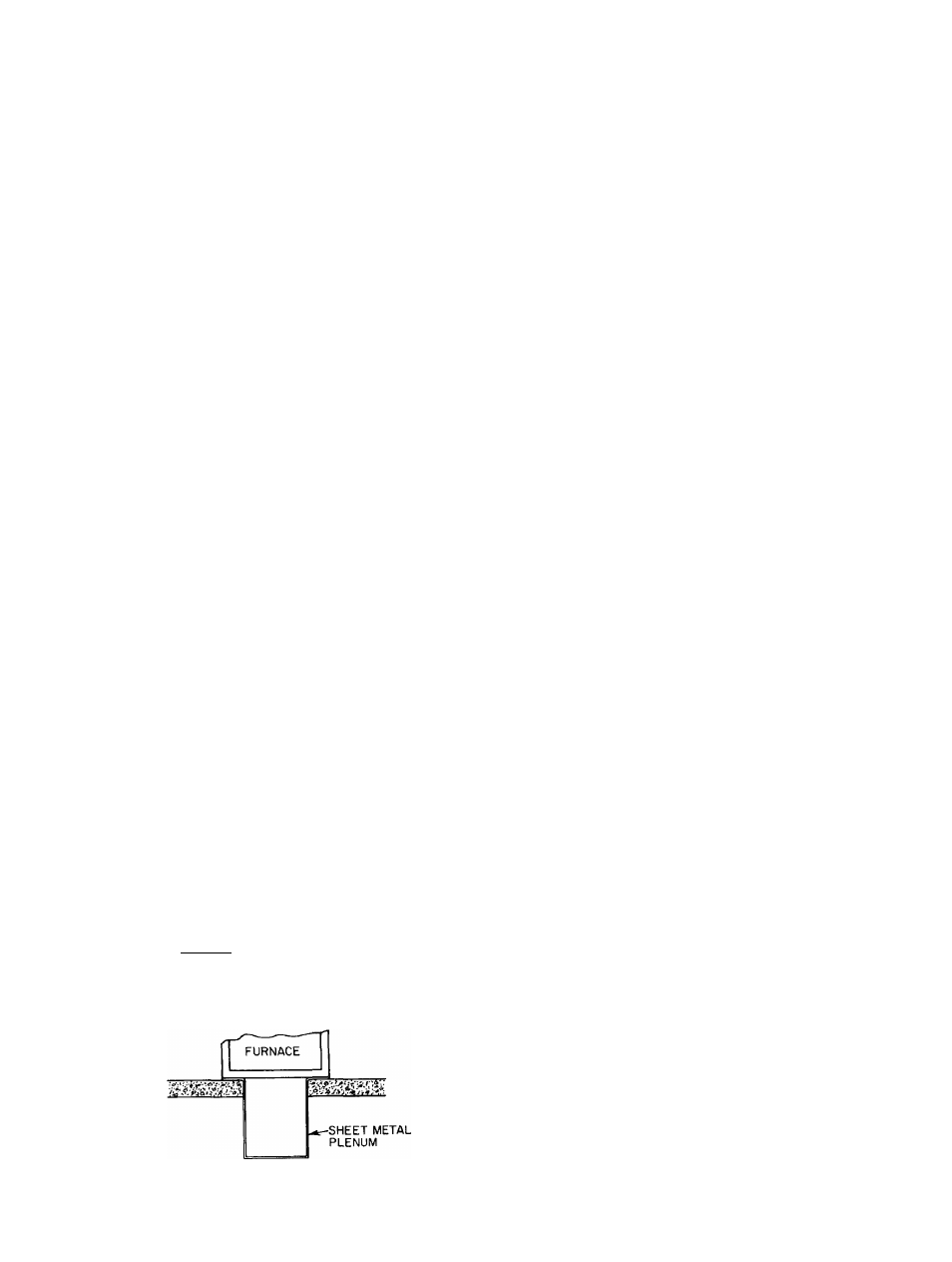

VII. FILTER ARRANGEMENT

The two factory-supplied filters are shipped in the blower

compartment. After the return air duct has been connected

to the furnace, install the filters in a V-formation inside the

return air plenum. See Figure 9.

Figure 5—Floor Opening

TABLE lll-FLOOR OPENING DIMENSIONS

MODEL 58DE SIZE

050...................

080,100

125

150

13

16V2

20

23 y.

m

Figure 6—Furnace on a Concrete Slab

VIII. STARTUP AND ADJUSTMENT

In addition to the following information, refer to “Proce

dures for Gas Furnace Installation” packaged with the unit.

Check heat exchanger tube mounting screws. Be sure all are

in place and tight.

A. Adjustment of Blower Speed

NOTE:

Some units have a shipping bracket supporting the

shaft end of the motor. This bracket should be removed and

discarded.

Heating Models—

lb change speed, unplug black wire ter

minal connector and reinsert at desired speed.

Air Conditioning Models—

Tb change cooling speed, unplug

black wire terminal connector and reinsert for desired speed.

For heating speed, unplug red terminal connector and rein

sert for desired speed.

B. Automatic Gas Control Valve

The automatic gas valve controls the flow of gas to both pilot

and main burners. The manual valve is built into the auto

matic gas valve body. The manual valve has only two posi

tions: OFF and ON. It does not have an intermediate posi

tion for pilot gas flow only.

If not already checked when lighting the main burner, check

the proper operation of this valve by moving the room ther

mostat pointer above and below room temperature and

observing that the main burners light on “call for heat” and

go off when the pointer is moved below the room tempera

ture setting.