A warning, Electrical controls and wiring, Table 6 — trouble analysis chart – Carrier 58DRC User Manual

Page 8: 58drc counterflow gas-fired furnaces

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOLING

58DRC

Counterflow Gas-Fired Furnaces

Cleaning Heat Exchanger — If it becomes neces

sary to clean the heat exchanger because of carbon

deposits, soot, etc., proceed as follows’

1. Turn off gas and electrical supply to furnace.

2. Remove front access doors

3. Remove vent pipe enclosure front and flue pipe.

4. Remove draft diverter. Screws are located inside

draft diverter opening.

5. Remove flue baffles from flue outlets of heat

exchanger.

6. Remove secondary air shield and burners. To remove

pilot burner, disconnect pilot supply tube at gas

valve.

7. Clean flue ways with brush and/or vacuum. Check

heat exchanger for leaks and cracks. Replace if

necessary.

8. Replace flue baffles. Be sure all screws are in place

and tight.

9 Replace draft diverter and vent connector. Be sure

screws are replaced and tight.

10. Using vacuum with soft brush attachment, clean

burners, then replace burners and secondary air

shield.

11. Turn on electricity first, then turn on gas. Check for

gas leaks.

A

WARNING

Never use a match or other open flame to check for

gas leaks. Use a soap-and-water solution.

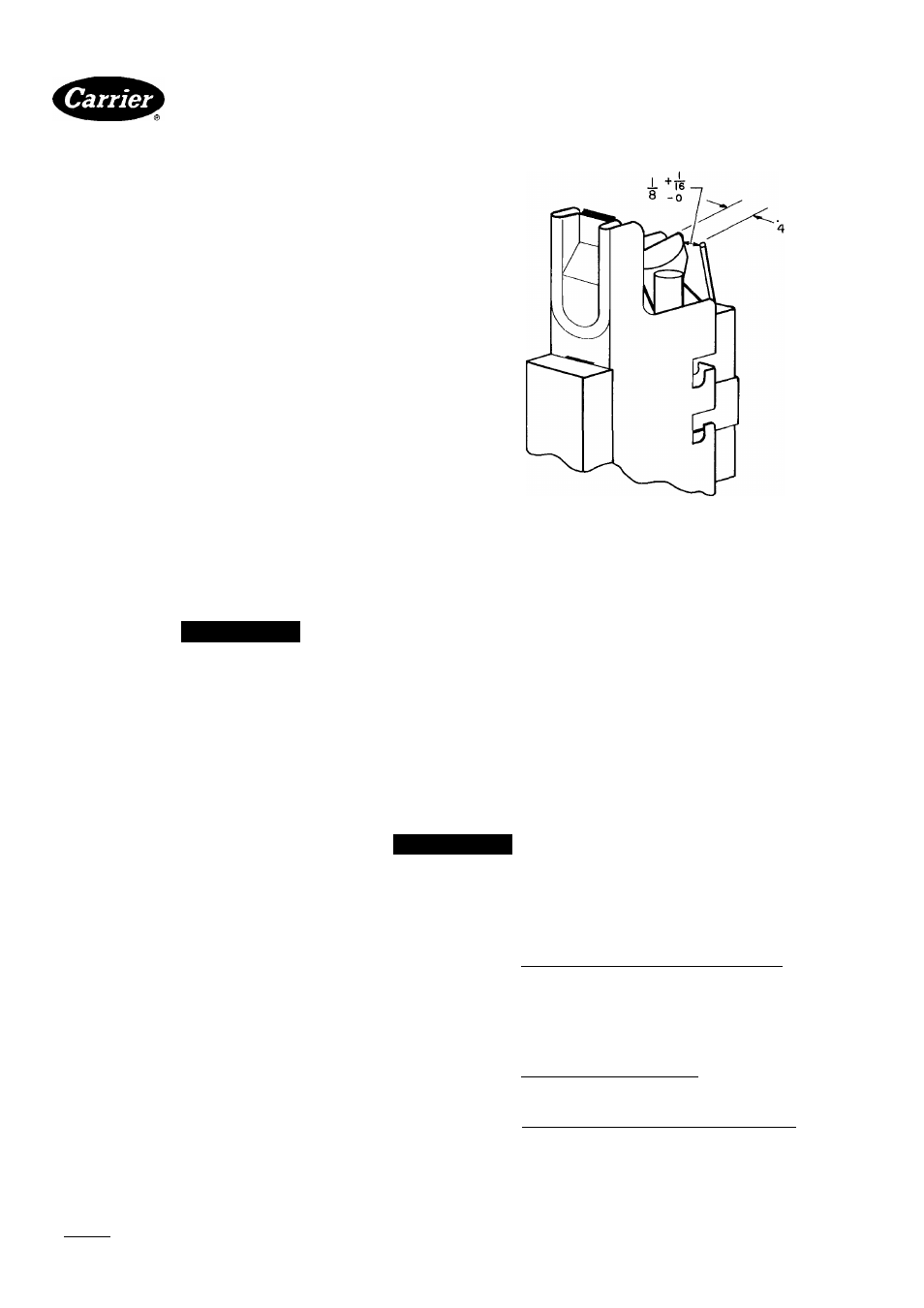

Pilot — See Fig. 15 Check the pilot and clean if neces

sary at the beginning of each heating season. The pilot

flame should be high enough to light the burners. Remove

the accumulation of soot and carbon from the sensing

probe.

I ■*'32

16

Fig. 15 — Position of Electrode to Pilot (in.)

Electrical Controls and Wiring

NOTE: There may be more than one electrical

supply to unit

With power disconnected to unit, check all electrical

connections for tightness. Tighten all screws on electrical

connections If any smoky or burned connections are

noticed, disassemble the connection, clean all parts and

stripped wire, and reassemble properly and securely.

Electrical controls are difficult to check without proper

instrumentation; therefore, reconnect electrical power

to unit and observe unit through one complete operating

cycle. If there are any discrepancies in the operating cycle,

contact your dealer and request service.

Table 6 — Trouble Analysis Chart

A

WARNING

Turn off gas and power supply to unit before servicing

(unless specific test requires gas and electric supplies)

SYMPTOM

CAUSE

REMEDY

Pilot will not light

No spark at electrode

Readjust, if necessary, so that gap between elec-

trode tip and pilot burner is as shown in Fig. 15.

Clean dirt or moisture accumulation from electrode

ceramic with cloth

Cracked

ceramic

assembly

replace pilot electrode

Check for loose or broken wiring at and between

spark generator and electrode Replace wire or

tighten connection as necessary______________________

Check fuse or circuit breaker for 115-volt supply to

furnace.

Check blower access panel for proper installation.

Check 24-volt input to spark generator. If reading is

24 volts, and above steps have been completed,

replace spark generator assembly

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookM |4

PC101

Catalog No 535-843

Printed in U S A

Form 58DRC-1 SI

Pg8

7-85

Replaces:New

For replacement items use Carrier Specified Parts

Tab I6al8a