A warning, 58drc counterflow gas-fired furnaces – Carrier 58DRC User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING & COOLING

58DRC

Counterflow Gas-Fired Furnaces

When the pilot flame is established, pilot 6H switches

its contacts in approximately 40 to 60 seconds, ener

gizing the main valve portion of gas valve 5F and de

energizing pilot igniter 6F and the PICK coil portion of

the pilot solenoid in gas valve 5F.

The main valve portion of gas valve 5F is heat motor

operated; therefore, after approximately 10 seconds, this

portion of the valve opens, permitting gas flow to the

main burners where the gas is ignited by pilot 6H

BLOWER CIRCUIT — With power through the solid-

state time-delay circuit on printed-circuit board 6C1 and

heat relay 2A, blower motor 3D is energized on heating

speed approximately 75 seconds after the pilot flame has

been proven

LIMIT CONTROL — If the furnace overheats for any

reason, limit control 7H1 switches, breaking the circuit

to automatic gas valve 5F The gas valve closes imme

diately, stopping gas flow to the main burners and the

pilot In addition, blower motor 3D continues to operate

because heat relay 2A is de-energized to cool down the

furnace.

Manual reset auxiliary limit switch 7H2 is located on

the top right-hand corner of the furnace. In the event

of blower motor failure, this switch breaks the electrical

circuit to the gas valve, stopping gas flow to the main

burners The switch must be manually reset after the

blower motor has been replaced.

Fusible link IIC is provided in the transformer lA

secondary circuit as protection from overheating con

ditions in the vestibule area of the furnace. Should this

condition exist, the fuse opens and de-energizes gas valve

5F and heat relay 2 A, stopping the gas flow to the burners

and starting blower motor 3D

When the thermostat is satisfied, the circuit between

R and W is broken, de-energizing automatic gas valve

5F, pilot 6H, and the solid-state time-delay circuit on

printed-circuit board 6C1. The gas flow stops imme

diately to the pilot and main burners with the BDP646

gas valve. After approximately 105 seconds, heat relay 2A

is energized and blower motor 3D stops.

MODEL 58GS/SE VENT DAMPER (when used) —

With gas and electrical power supplied to the furnace, the

vent damper is in the closed position. On a call for heat

by the thermostat, the vent damper motor is energized

and the damper opens. When the damper reaches full

open position, the transformer energizes the gas valve.

When the thermostat is satisfied, it de-energizes the

gas valve and stops the gas flow. The vent damper motor

energizes and closes the damper. The damper remains

closed until the next thermostat cycle.

COOLING (cooling models only) — When the thermo

stat calls for cooling, power from transformer lA ener

gizes the condensing unit contactor, cooling relay coil 2F,

closing its contacts and energizing blower motor 3 D on its

cooling speed. It continues to operate until the thermostat

is satisfied.

When the thermostat is satisfied, the circuit to ter

minal Gc is broken, de-energizing cooling relay coil 2F

which, in turn, opens its contacts, stopping blower motor

3D.

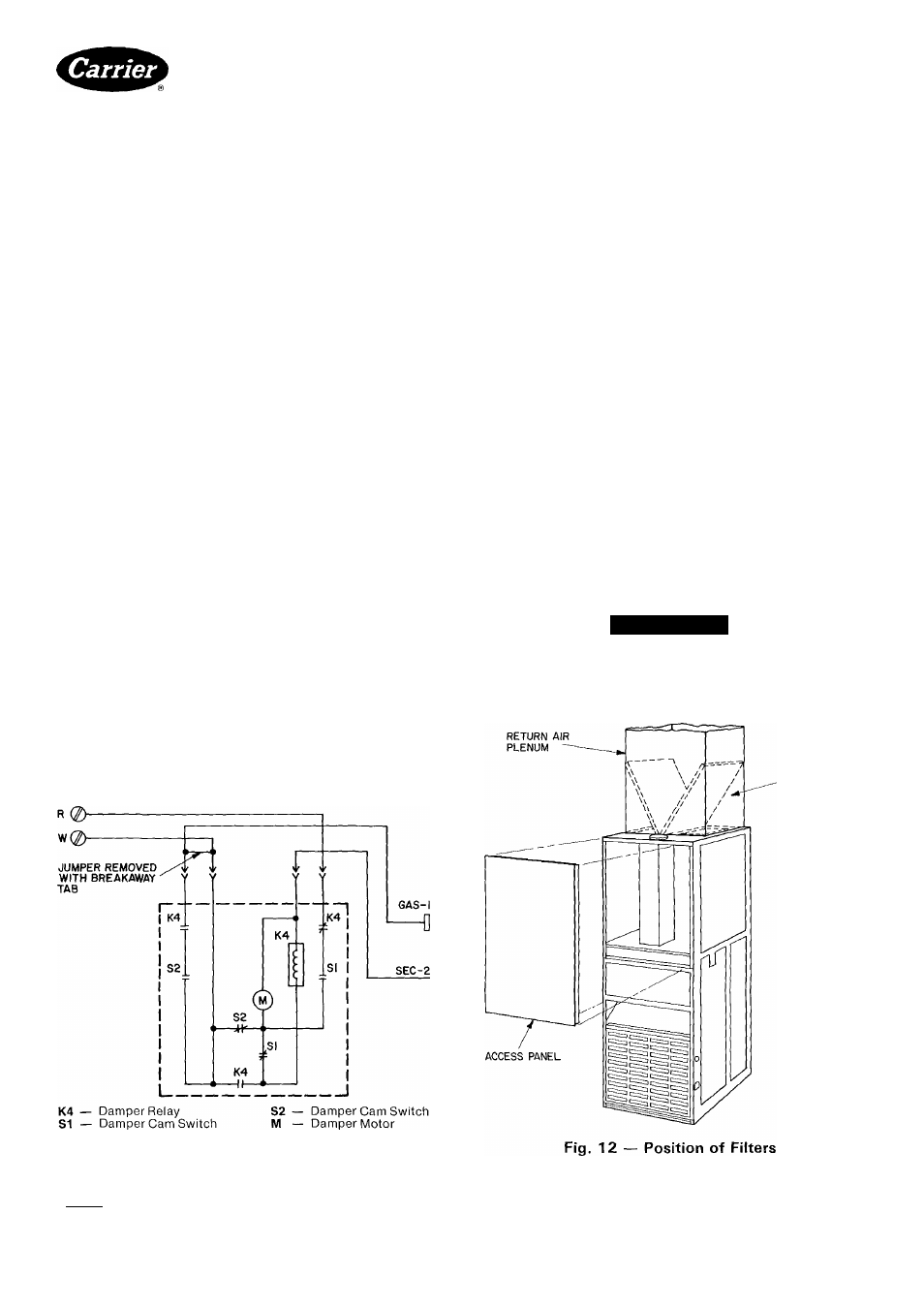

Filter Arrangement — The 2 factory-supplied filters

are shipped in the blower compartment. After the return-

air duct has been connected to the furnace, install the

filters in a V-formation inside the return-air plenum. See

Fig. 12.

A WARNING

Never operate unit without a filter or with filter

access door removed.

Fig. 11 — Circuit for 58GS/SE Vent Damper

INSTALLATION

POSITION

OF FILTERS

Manufacturer reserves the right to discontinue, or change at any time, specilications or designs without notice and without incurring obligations.

Book[1 [4

PC101

Catalog No 535-843

PrintedinUSA

Form58DRC-1SI

Pg5

7-85

Replaces: New

----------------- iromc iiQA Carrier Soecifled Parts