Sequence of operation, 58drc counterflow gas-fired furnaces – Carrier 58DRC User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

HEATING A COOUHG

58DRC

Counterflow Gas-Fired Furnaces

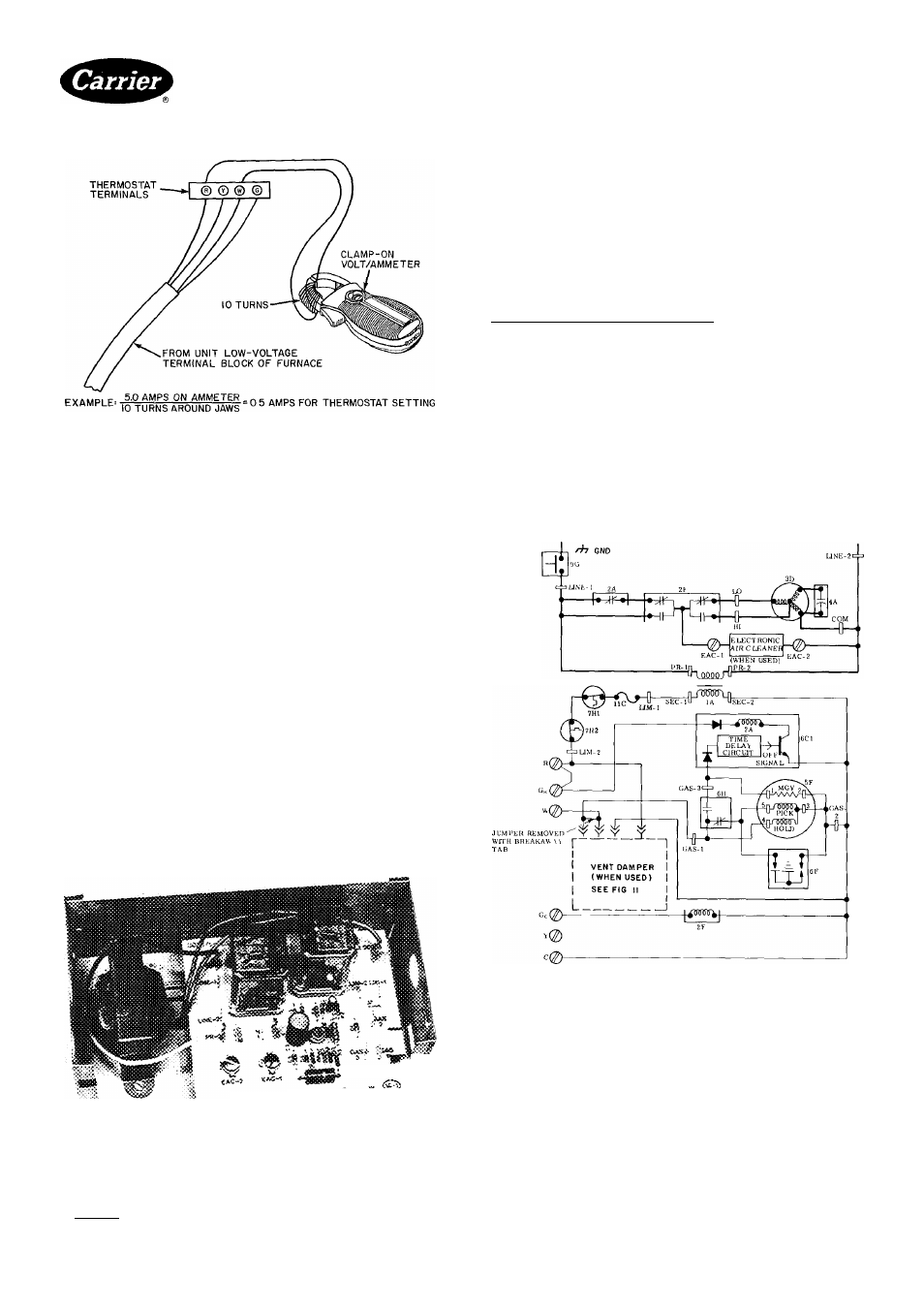

Fig. 8 — Amp Draw Check with Ammeter

The room thermostat should be located where it will

be in the natural circulation path of room air. Avoid loca

tions where the thermostat would be exposed to cold-air

infiltration, drafts from windows, doors, or other open

ings leading to the outside, or exposure to air currents

from warm- or cold-air registers; or to exposure where

the natural circulation of the air iS- cut off — such as

behind doors, above or below mantels, shelves, etc

The thermostat should not be exposed to heat from

nearby fireplaces, radios, televisions, lamps, or rays from

the sun. Nor should the thermostat be mounted on a wall

containing pipes or warm-air ducts, or a flue or vent that

could affect its operation and prevent it from properly

controlling the room temperature. Any hole in the plaster

or panel through which the wires pass from the thermo

stat should be adequately sealed with suitable material to

prevent drafts from affecting the thermostat

PRlNTED-ClRCUlT CONTROL CENTER — Each

furnace features a printed-circuit control center. This will

aid the installer and service technician when installing and

servicing the unit. See Fig. 9. A low-voltage terminal

board is marked for easy connection of field wiring.

4 и

^ Н

Fig. 9 — Printed-Circuit Control Center

Sequence of Operation

NOTE; The wiring diagram shown in Fig. 10 is for

heating/cooling units.

HEATING — Gas and electrical supplies must be turned

on at the furnace.

NOTE; When power is applied to heat relay coil 2 A in the

control circuit, the normally closed contacts in the blower

circuit will open.

BDP 646 Gas Valve (HD Models) — When the thermo

stat calls for heat, the control circuit is closed between

terminals R and W. Power from transformer 1A through

fusible link 11C and limit switches 7H1 / 7H2 energizes the

pilot valve portion of automatic gas valve 5F and pilot

igniter 6F. The pilot valve opens, permitting gas flow to

the pilot burner where it is ignited.

The pilot valve portion of automatic gas valve 5F is a

solenoid consisting of a PICK and a HOLD coil. Both

the PICK and the HOLD coils must be energized to open

the valve, but only the HOLD coil must be energized to

keep it open

1A

2A

2F

3D

4A

5F

6C1

6F

6H

Transformer 115/24

Relay-Heat (SPST-

N C )

Relay-Cool (DPDT)

Blower Motor

Run Capacitor

Gas Valve (2-Circuit)

Printed-Circuit Board

Piiot Igniter

Safety Pilot (Flame

Sensing)

7H1

— Limit Switch (SPST-

N C )

7H2

— Auxiliary Limit Switch

(SPST-N C ) Manual

Reset

Summer/Winter

Switch (if equipped)

Blower Door Switch

(SPST-N O )

Fusible Link

9A

9G —

11C

Fig. 10 — Line-to-Line Wiring Diagram for

Sizes 045-095 IID Natural Gas

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Book|1 14

PC101

Catalog No 535-843

Printed in U S A

Form 58DRC-1 SI

Pg4

7-85

Replaces:New

ronlanorvionf Home iica

Cna^iticw4 Dat-fc