Notes on connecting and operating the controller – VACUUBRAND CVC 3000 E User Manual

Page 27

Notes on connecting and operating the controller

Valves and/or vacuum pumps are necessary to operate the control-

ler.

Without those components the controller can be used only as vacuum

measurement device.

When used as measurement device, the controller can switch a possibly

connected coolant valve.

The CVC 3000 E is equipped with an internal capacitive pressure trans-

ducer with ceramic diaphragm. It measures the actual pressure indepen-

dently of the gas type, and with reference to the vacuum, i.e., absolute.

➨

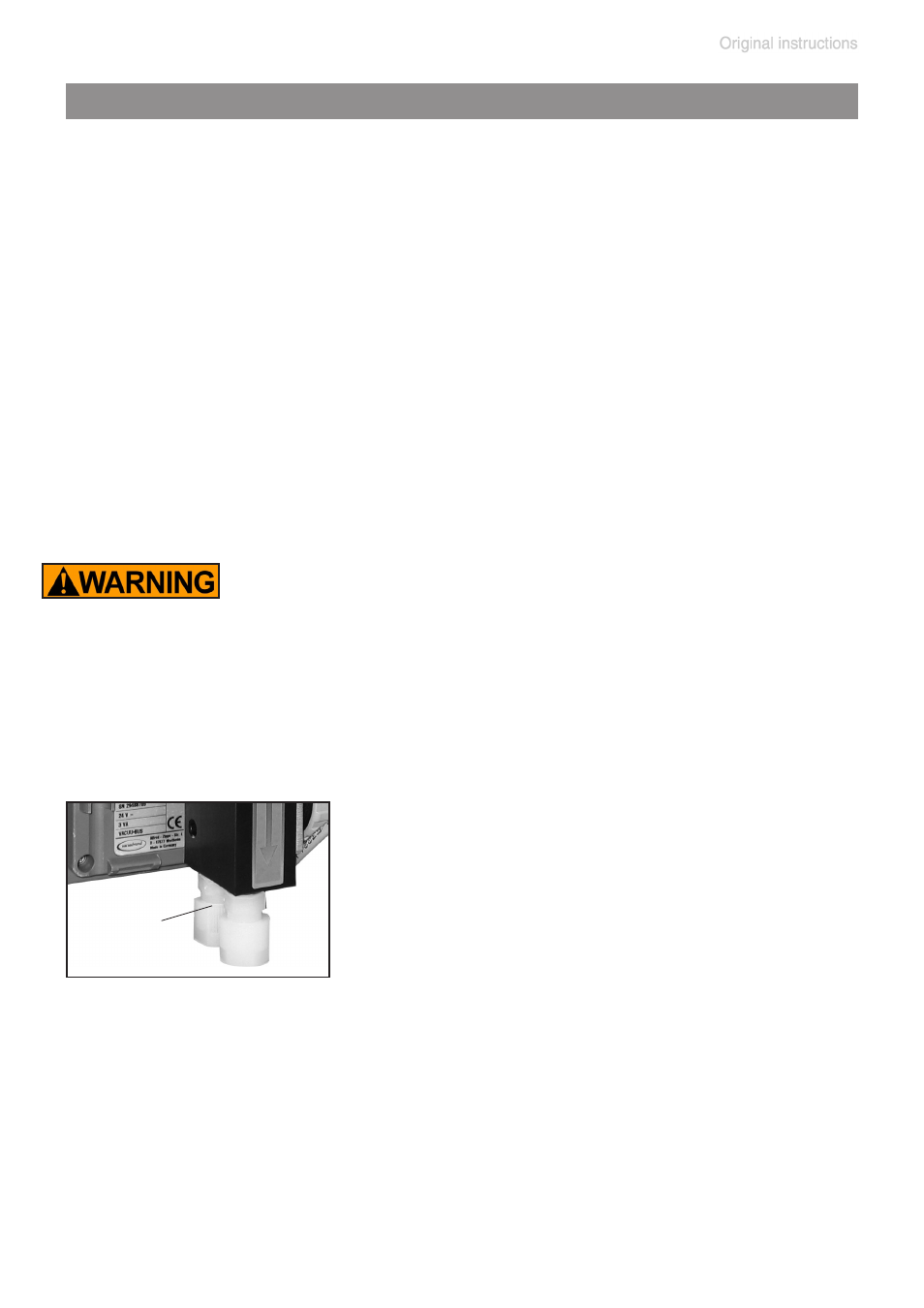

Connect the vacuum connection of the controller via PTFE tubing to

the vacuum application and to the vacuum pump.

+

Maximum permissible pressure: 21.8 psi (1.5 bar) ab-

solute.

Attention: At pressures above approximately 795 Torr

(1060 mbar) the pressure reading becomes incorrect

due to saturation of the pressure transducer. The dis-

play flashes. Release pressure immediately!

Risk of

bursting!

- Position the CVC 3000 E controller and its

vacuum line in such a way that condensate

cannot flow towards the pressure transduc-

er. Condensate and deposits will affect the

measurement results. Clean the pressure

transducer, if necessary. See section “Clean-

ing the pressure transducer”, pg. 55.

- Inside a vacuum system where evaporation occurs, e.g., a rotary

evaporator, the vacuum is not uniform. For example, a condenser can

act as a pump, or the vacuum in the connecting tubing can be higher

or lower than in the application itself. This affects the measurement

results as well as the control levels. Therefore, carefully choose the

position where to connect the pressure transducer.

- If residues occur or when working with aggressive or condensable

substances, install a gas washing bottle in front of the pressure trans-

ducer.

vacuum

connection

to application