Notice – VACUUBRAND MD 1C VARIO-SP User Manual

Page 51

page 51 of 87

➨

Air and pumped media might react inside the pump or

at the outlet of the pump and form hazardous or explo-

sive mixtures, when you use air rather than inert gas

for the gas ballast. This constitutes a risk of significant

damage to equipment and/or facilities, a risk of per-

sonal injury or even loss of life.

+

Make sure that air/gas intake through the gas ballast

valve can never lead to hazardous, explosive or other-

wise dangerous mixtures. If in doubt, use inert gas.

To reduce condensation in the pump, do not pump vapor

before the pump has reached its operating temperature.

Open the gas ballast valve when pumping condensable

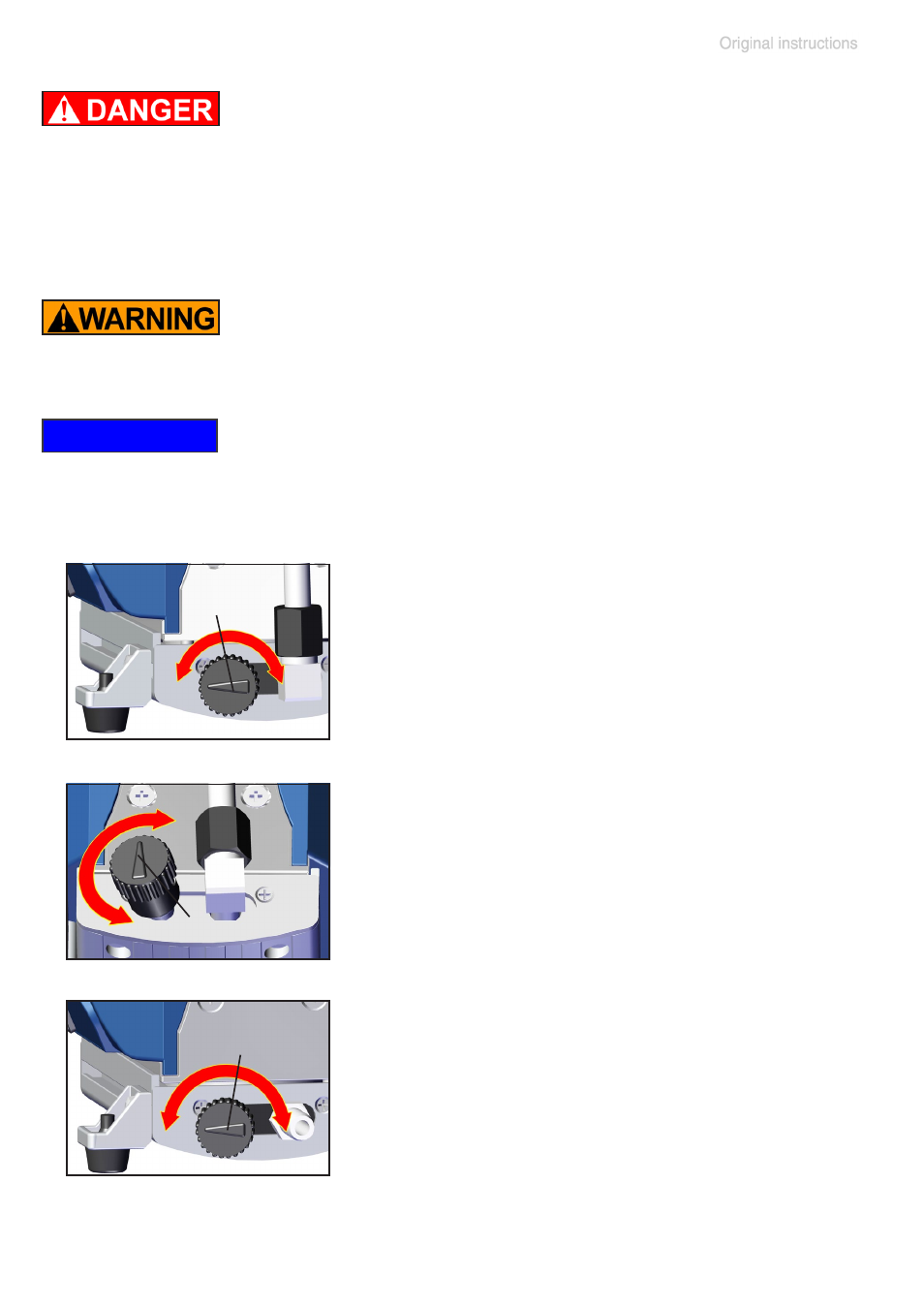

vapors. Turn gas ballast cap to open valve.

NOTICE

gas ballast

(open)

For

condensable vapors (water vapor, sol-

vents, etc.):

- The gas ballast valve is open if the arrow

on the gas ballast cap is pointing away from

the pump (

MD 1C / MD 1C VARIO-SP), re-

spectively towards the pump (

MD 1C + AK

+ EK) or away from the inlet (MZ 1C) (see

figures).

- With gas ballast valve open, the ultimate

vacuum will be reduced.

- Use inert gas for gas ballast to avoid the

formation of explosive mixtures.

Attention:

maximum supply pressure of inert gas: 17.5

psi (1.2 bar) absolute.

- Close the gas ballast valve by turning the

cap 180°.

In case of low boiling solvents (when the for-

mation of condensate is unlikely), the use of

gas ballast might be unnecessary. Operating

the pump without gas ballast increases the

solvent recovery rate at the exhaust waste va-

por condenser (EK).

gas ballast (open)

MD 1C + AK + EK

MD 1C / MD 1C VARIO-SP

gas ballast

(open)

MZ 1C