Notice – VACUUBRAND MV 10 NT VARIO User Manual

Page 92

page 92 of 126

+

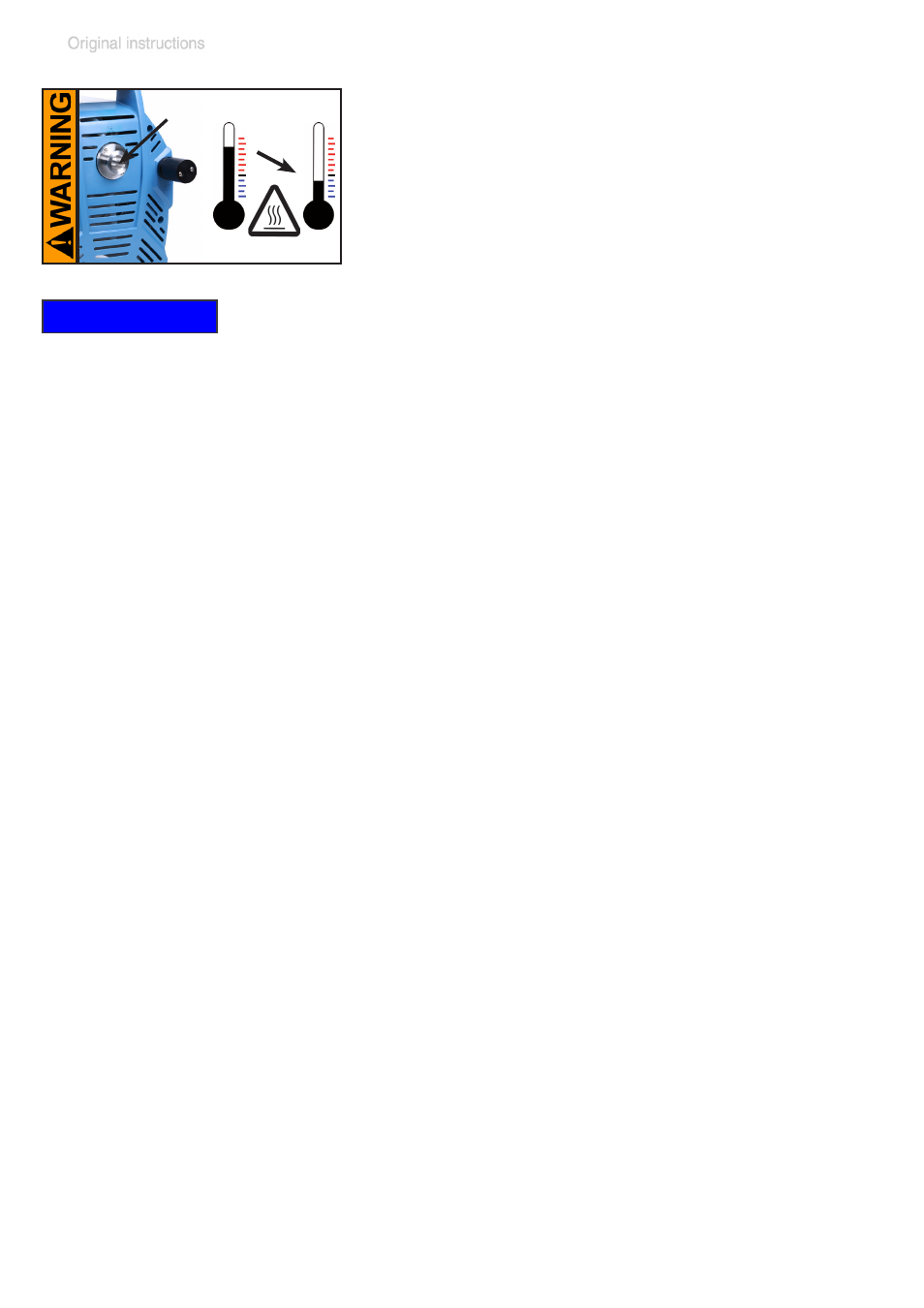

Allow sufficient cooling of the pump before

starting maintenance.

+

Vent the pump and isolate it from the

vacuum system before you start mainte-

nance. Drain condensate, if applicable.

Ensure that maintenance is done only by suitably

trained and supervised technicians.

The valves and diaphragms are wear parts. If the rated

ultimate vacuum is no longer achieved or in case of in-

creased noise level, the pump interior, the diaphragms

and the valves must be cleaned and the diaphragms and

valves must be checked for cracks or other damage.

All bearings are encapsulated and are filled with long-life

lubricant. Under normal operating conditions, the drive

system is maintenance free.

In demanding circumstances, it may be efficient to check

and clean the pump heads on a regular basis. In normal

use, the lifetime of the diaphragms and valves is typically

15,000 operating hours.

- Prevent internal condensation, transfer of liquids or

dust. The diaphragms and valves will be damaged if

liquid is pumped in significant amount.

- Carry out maintenance frequently if the pump is ex-

posed to corrosive media or in case of deposits.

- Regular maintenance will improve the lifetime of the

pump and also protect both users and the environment.

NOTICE

+

Service only one side of the pump at a time to avoid the mixing of

parts.

+

In case, support the pump appropriately.

Set of seals for ME 16 NT VARIO ................................................................696819

(diaphragms and valves)

Set of seals for MD 12 NT VARIO, MV 10 NT VARIO .................................696827

(diaphragms, valves and O-rings)

Diaphragm key (w/f 66) ...............................................................................636554

atm

°C / °F