How to determine the best distillation conditions – VACUUBRAND PC 620 User Manual

Page 37

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. Manual-no.: 999029 / 01/10/2009

page 37 of 48

How to determine the best distillation conditions

Determine the temperature of the available coolant.

☞ In most cases the coolant temperature is given (e. g. tap water, in house cooling water circuit). For

maximum solvent recovery, carefully choose the boiling point of the product (by choosing the vacuum

level) and the bath temperature accordingly.

☞ Determine the lowest boiling point of the product (solvent).

☞ The temperature difference between boiling point of the product and the coolant should be more than

20°C, otherwise low vacuum level will lead to significant loss of solvent.

☞ Select a water bath temperature of 20-30°C above the boiling point of the product to provide sufficient

heat transfer.

Determine the bath temperature

☞ If there is no limitation from the product side, a water bath temperature of 60-70°C is usually recom-

mended (efficient heating with minimum generation of water vapour from the bath).

Example:

☞ Cooling temperature assumed to be 15-20°C.

☞ Water bath temperature between 60-70°C. Wait until temperature is reached.

☞ Determine the vacuum level for a boiling point (use published data of solvents). Reduce pressure until

a sufficient level of evaporation is attained.

☞ If hysteresis is set manually, avoid frequent operation of the in-line valve (approx. not more than two

operations per minute).

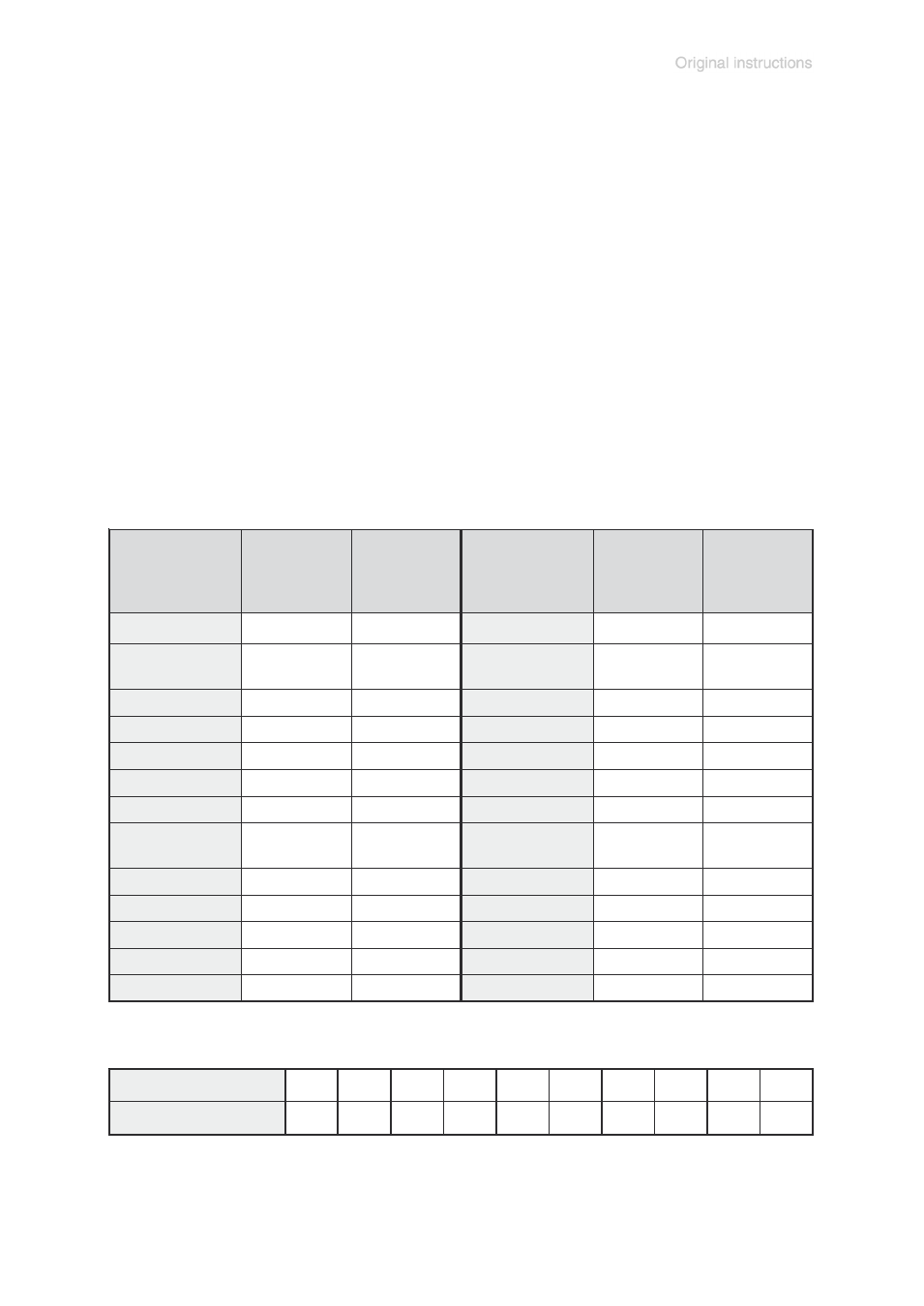

List of solvents

Appropriate selection of

ΔΔΔΔΔp

-

Choose

Δp in a range from 5 mbar (high boiling solvents, e. g. water, toluene) to 150 mbar (low boiling

solvents, e. g. methanol, dichloromethane).

r

a

b

m

p

5

0

1

0

5

0

8

0

0

1

0

0

2

0

0

5

0

0

7

0

0

9

0

0

0

1

ΔΔΔΔΔ

r

a

b

m

p

2

3

5

0

1

5

1

5

3

0

7

0

9

0

2

1

0

5

1

t

n

e

v

l

o

S

t

n

i

o

p

g

n

i

l

i

o

B

3

1

0

1

t

a

)

C

°

(

r

a

b

m

r

o

f

m

u

u

c

a

V

t

n

i

o

p

g

n

i

l

i

o

b

)

.

s

b

a

(

)

r

a

b

m

(

T

t

a

s

C

°

0

4

=

t

n

e

v

l

o

S

t

n

i

o

p

g

n

i

l

i

o

B

3

1

0

1

t

a

)

C

°

(

r

a

b

m

r

o

f

m

u

u

c

a

V

t

n

i

o

p

g

n

i

l

i

o

b

)

.

s

b

a

(

)

r

a

b

m

(

T

t

a

s

C

°

0

4

=

e

n

o

t

e

c

A

6

5

6

5

5

e

t

a

t

e

c

a

l

y

h

t

E

7

7

0

4

2

e

l

i

r

t

i

n

o

t

e

c

A

2

8

0

3

2

-

e

n

e

l

y

h

t

E

e

d

i

r

o

l

h

c

i

d

3

8

0

1

2

e

n

e

z

n

e

B

0

8

6

3

2

e

n

a

x

e

H

9

6

5

3

3

l

o

n

a

t

u

B

-

t

2

8

0

3

1

l

o

n

a

h

t

e

M

4

6

7

3

3

l

o

n

a

t

u

B

-

1

8

1

1

5

2

e

n

a

t

n

e

P

6

3

0

0

0

1

>

m

r

o

f

o

r

o

l

h

C

2

6

4

7

4

l

o

n

a

p

o

r

p

o

s

I

2

8

7

3

1

e

n

a

x

e

h

o

l

c

y

C

1

8

5

3

2

e

n

i

d

i

r

y

P

5

1

1

0

6

e

n

a

h

t

e

m

o

r

o

l

h

c

i

D

0

4

0

0

0

1

-

o

r

o

l

h

c

a

r

t

e

T

e

n

a

h

t

e

m

7

7

1

7

2

r

e

h

t

e

l

y

h

t

e

i

D

5

3

0

0

0

1

>

e

n

a

r

u

f

o

r

d

y

h

a

r

t

e

T

6

6

7

5

3

r

e

h

t

e

l

y

p

o

r

p

o

s

ii

D

8

6

5

7

3

e

n

e

u

l

o

T

1

1

1

7

7

e

d

i

m

a

m

r

o

fl

y

h

t

e

m

i

D

3

5

1

1

1

e

n

e

l

y

h

t

e

o

r

o

l

h

c

i

r

T

7

8

3

8

1

e

n

a

x

o

i

D

-

4

,

1

1

0

1

7

0

1

e

n

e

l

y

X

8

3

1

5

2

l

o

n

a

h

t

E

8

7

5

7

1

r

e

t

a

W

0

0

1

2

7

Note: Changing set point p while process control is stopped leads at the same time to automatic preselection

of

Δp. During process control hysteresis is adapted only in case of great set point changes. Hysteresis Δp

can be changed manually at any time.