Accessories, Venting, Minimising cooling water consumption – VACUUBRAND MV 10C VARIO User Manual

Page 38: Vacuum distribution

page 38 of 51

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999073 / 15/12/2009

Accessories

Base plate with exhaust waste vapour

condenser and collecting flask ........................... 69 99 49

Venting

Venting valve VB M2 24 V= ..................................... 66 68 17

Minimising cooling water consumption

Coolant valve 24 V= ................................................. 67 60 13

-

compact design, designed for a high number of operations

at short intervals

-

splash-proof solenoid systems

-

flow rate optimised for applications with rotary evaporator

and exhaust waste vapour condenser

Set of casters ......................................................... 69 99 81

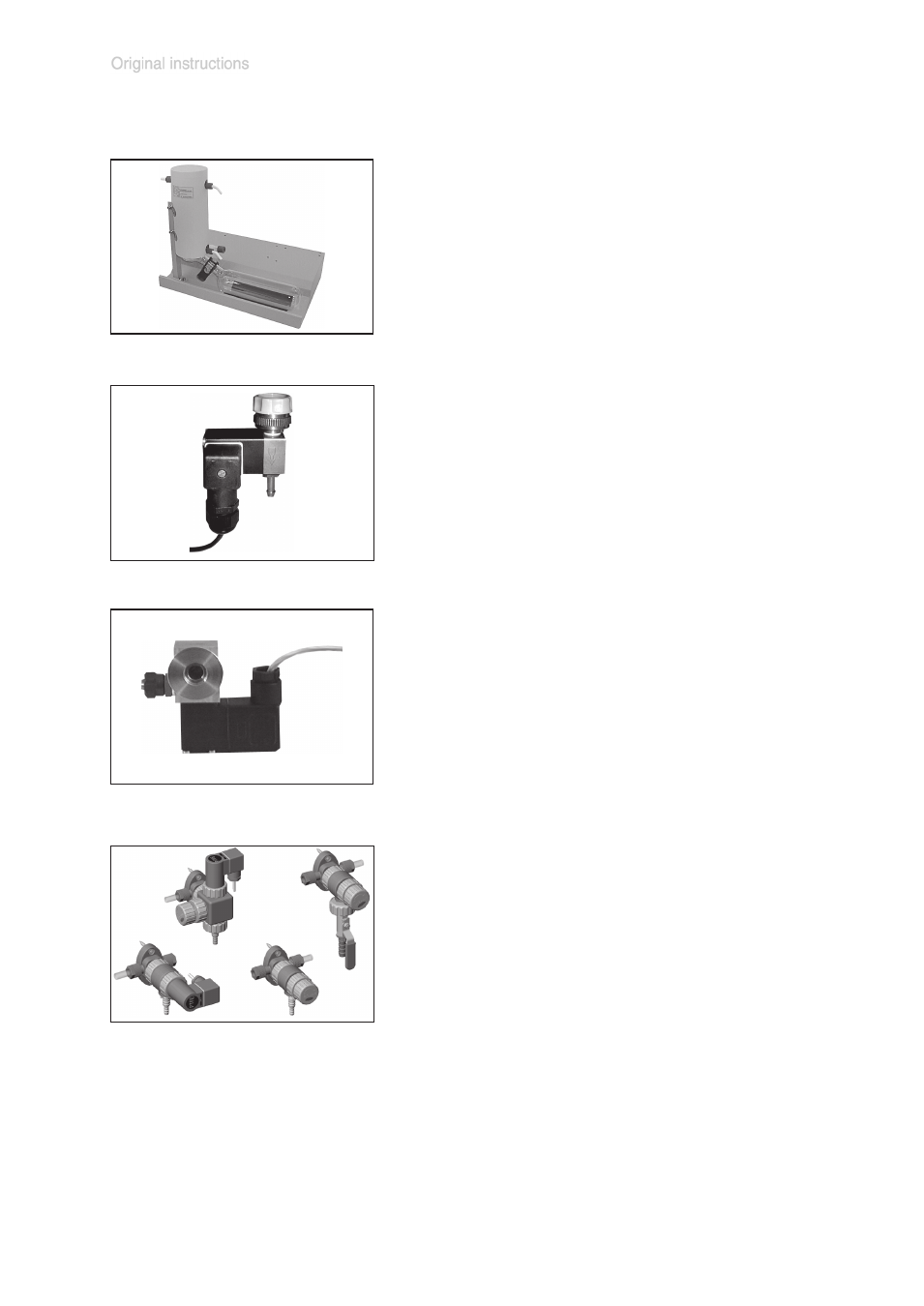

Vacuum distribution

VACUU•LAN

®

manual flow control

module VCL 01 ...................................................... 67 71 06

VACUU•LAN

®

shut off-/ manual flow control

module VCL 02 ...................................................... 67 71 07

VACUU•LAN

®

automatic control module

VCL 10 .................................................................... 67 71 08

VACUU•LAN

®

manual flow control/automatic

control module VCL 11 ......................................... 67 71 09

The VACUU•LAN

®

modules allow process orientated, flexible

and cost effective connections according to the requirements:

One vacuum pump for multiple work stations.

On this page we offer only a small selection of VACUU•LAN

®

options. Please refer for further information.

VCL 01

VCL 10

VCL 02

VCL 11