Basic setup continuous pumping – VACUUBRAND MV 10C VARIO User Manual

Page 28

page 28 of 51

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. manual-no.: 999073 / 15/12/2009

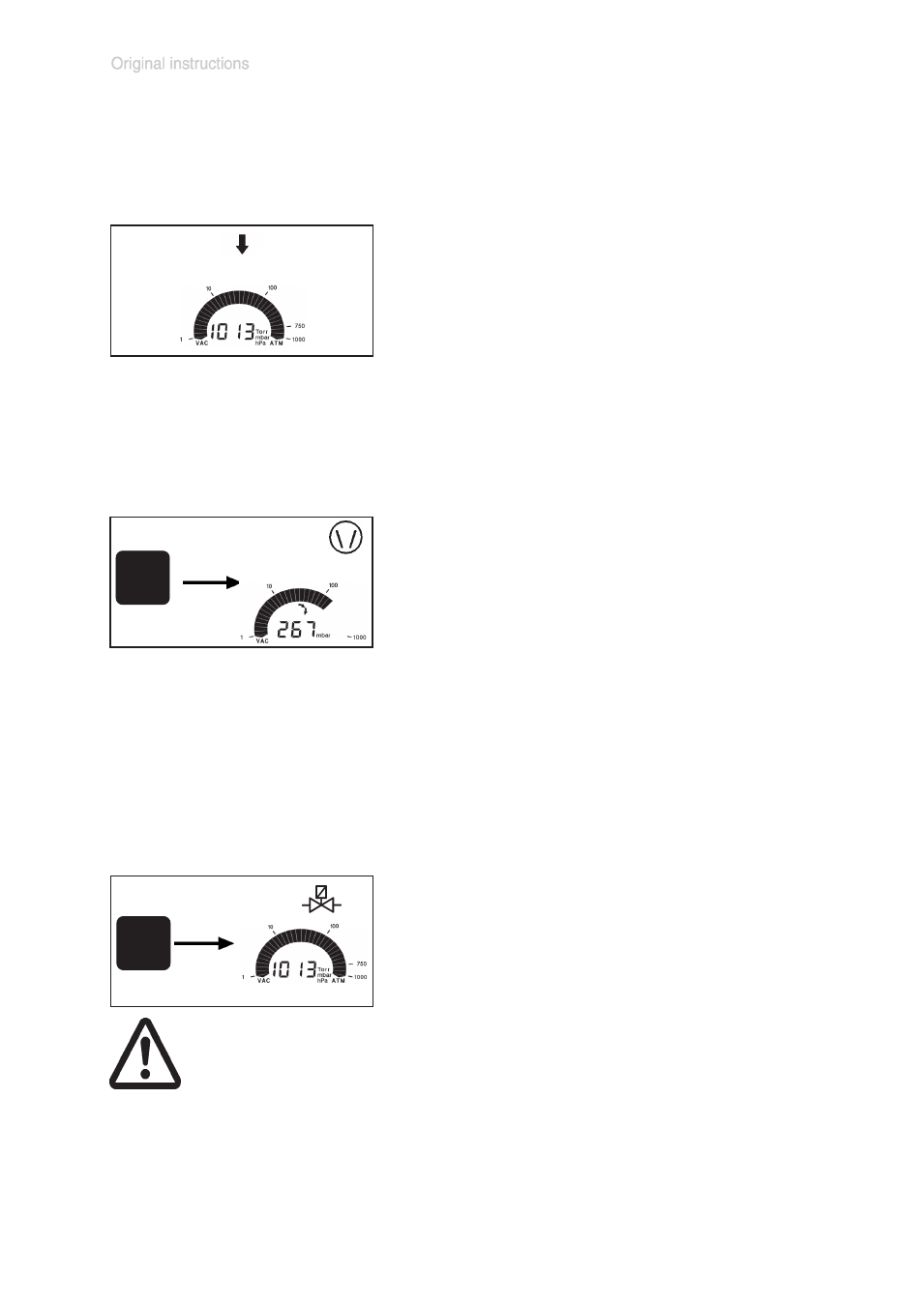

Basic setup continuous pumping

START

STOP

The process control is not active, i. e. the controller is ready for

vacuum control, but control operation has not been started.

☞ The mode as from last operation is reactivated (after first

switching on ”vacuum control” (factory-set) is displayed).

☞ The actual pressure is displayed.

☞ Values as from last operation are reactivated.

☞ Press key START/STOP to start process control.

☞ If a coolant valve should be operated, the coolant valve has

to be preselected, see section ”Changing the basic setup”.

After switching on

Starting and stopping the process control

➨ Starting process control: Press key START/STOP.

☞ If a coolant valve is preselected: Coolant valve opens im-

mediately, the symbol is displayed.

➨ Stopping process control: Press key START/STOP.

☞ The pump is switched off.

☞ Attention: Adopt suitable measures if there is a possible

pressure increase after switching off the pump, e. g. due to

low boiling solvents.

☞ If a coolant valve is preselected: The coolant valve continu-

ous to run for another 5 minutes to allow condensation of

vapours which remain in the system. Symbol ”cooling water”

is flashing.

Venting

(only possible if an external venting valve is connected and configurated)

VENT

Attention: If pressurized

inert gas is used install an

overpressure relief valve.

Max. permitted pressure

at controller: 2 bar

absolute. Ensure that high

pressure is compatible

with the mechanical

stability of the system!

Short venting, e.g. in case of boiling retardation or if sudden

foaming occurs:

➨ Press key VENT shortly (< 2 sec.).

☞ Process control is stopped as if START/STOP was pressed.

Venting the system:

➨ Press key VENT continuously (> 2 sec.) until symbol ”vent-

ing valve” is flashing.

☞ Process control is stopped as if START/STOP was pressed.

☞ Ventilation until pressure does not change any more, i. e.

until atmospheric pressure is attained.

☞ Key START/STOP interrupts venting at any time.