Storage, Fan troubleshooting chart – Twin City BCRFS Belt Driven Centrifugal Filtered Supply Fans - IM-4310 User Manual

Page 6

6

Twin City IM-4310

Storage

If fans are stored for any length of time, they should be stored in a clean, dry location to prevent rust and corrosion.

Outdoor storage is not recommended. When outdoor storage is necessary, fans should be protected from the elements as

completely as possible. Cover the fan inlet and outlet and keep motors dry and clean.

For extended storage (more than 3 months) motor shafts and bearings should be rotated monthly. If stored longer than 6

months, bearing grease in motor and fan should be purged and replaced with compatible grease. Belts should be rechecked

for proper tension. Storage records should be kept to assure proper maintenance. The factory can advise warranty centers

to provide motor and bearing service if needed.

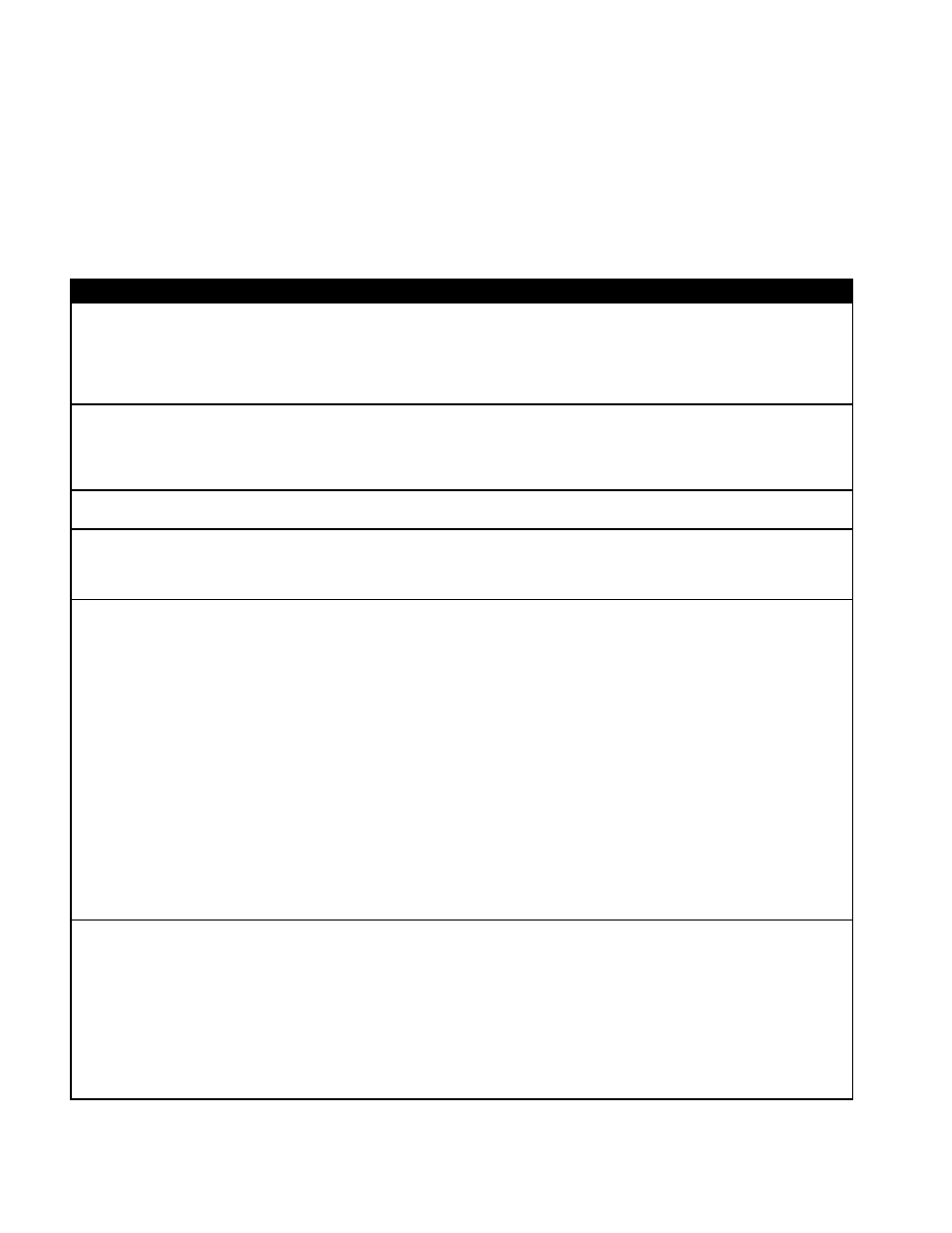

PROBLEM

POSSIBLE CAUSES

FAN DOES NOT OPERATE

1. Wrong voltage.

2. Electricity turned off or not wired properly.

3. Tripped overload protector.

4. Blown fuses.

5. Loose pulleys.

6. Broken belts.

TOO LITTLE AIR

1. Wheel rotating in wrong direction.

2. Fan speed lower than design.

3. System is more restrictive (more static pressure) than expected.

4. Restricted fan inlet or outlet.

5. Filters are dirty or clogged.

TOO MUCH AIR

1. Fan speed higher than design.

2. System is less restrictive (less static pressure) than expected.

EXCESSIVE HORSEPOWER

1. Wheel rotating in wrong direction.

2. Wheel rubbing on inlet venturi.

3. Fan speed higher than design.

4. Worn fan bearings.

EXCESSIVE NOISE

1. Wheel or sheaves loose.

2. Bearing or drive misalignment.

3. Accumulation of material on wheel.

4. Worn or corroded wheel.

5. Wheel out of balance.

6. Wheel hitting housing.

7. Bent shaft.

8. Bearings need lubrication.

9. Loose bearing bolts.

10. Loose or worn bearings.

11. Mismatched belts.

12. Belts too loose or too tight.

13. Belts oily or dirty.

14. Belts worn.

15. Loose fan mounting bolts.

16. Rattle of components in high velocity airstream.

17. Electrical noise.

18. Noise from high velocity air system.

19. Vibrating parts not isolated from building.

20. Vibrating ductwork.

EXCESSIVE VIBRATION

1. Wheel or sheaves loose on shaft.

2. Wheel out of balance.

3. Excessive buildup of dirt/dust on wheel.

4. Belts too loose or too tight.

5. Mismatched belts.

6. Bent shaft.

7. Bearing or drive misalignment.

8. Loose or worn bearings.

9. Fan mounting bolts loose.

10. Weak mounting base for fan.

11. Curb not flat and level.

It is recommended that the users and installers of this shipment familiarize themselves with AMCA Publication #201,

“Fans and Systems” and publication #202, “Troubleshooting” which are published by the Air Movement and Control

Association (AMCA), 30 West University Drive, Arlington Heights, Illinois 60004. www.amca.org

Fan Troubleshooting Chart