General installation, Check, test & start procedure, Electrical connection – Twin City DBS / DBT Forward Curved Inline Duct Blowers - IM-4220 User Manual

Page 2: Warning

2

Twin City IM-4220

General Installation

CAUTION: Sheet metal parts, screws, clips and similar

items inherently have sharp edges, and it is necessary

that the installer and service personnel exercise cau-

tion.

The installation of this equipment shall be in accordance

with the regulations of authorities having jurisdiction and

with all applicable codes.

This equipment is to be installed by an experienced

installation company and fully trained personnel.

The mechanical installation of the inline centrifugal fan

consists of making final connections between the unit,

building services, and duct connections.

Check, Test & Start Procedure

WARNING

Electric shock hazard. Could cause severe injury or

death. Failure to bond the frame of this equipment

to the building electrical ground by use of the

grounding terminal provided or other acceptable

means may result in electrical shock. Disconnect

electric power before servicing equipment. Service

to be performed only by qualified personnel.

BEFORE START-UP: Disconnect power to this unit

before servicing the unit.

1. Check to verify that the wheel is free to rotate.

2. Verify that supply voltage on the line side of discon-

nect agrees with voltage on fan data plate and is

within the 10% utilization voltage.

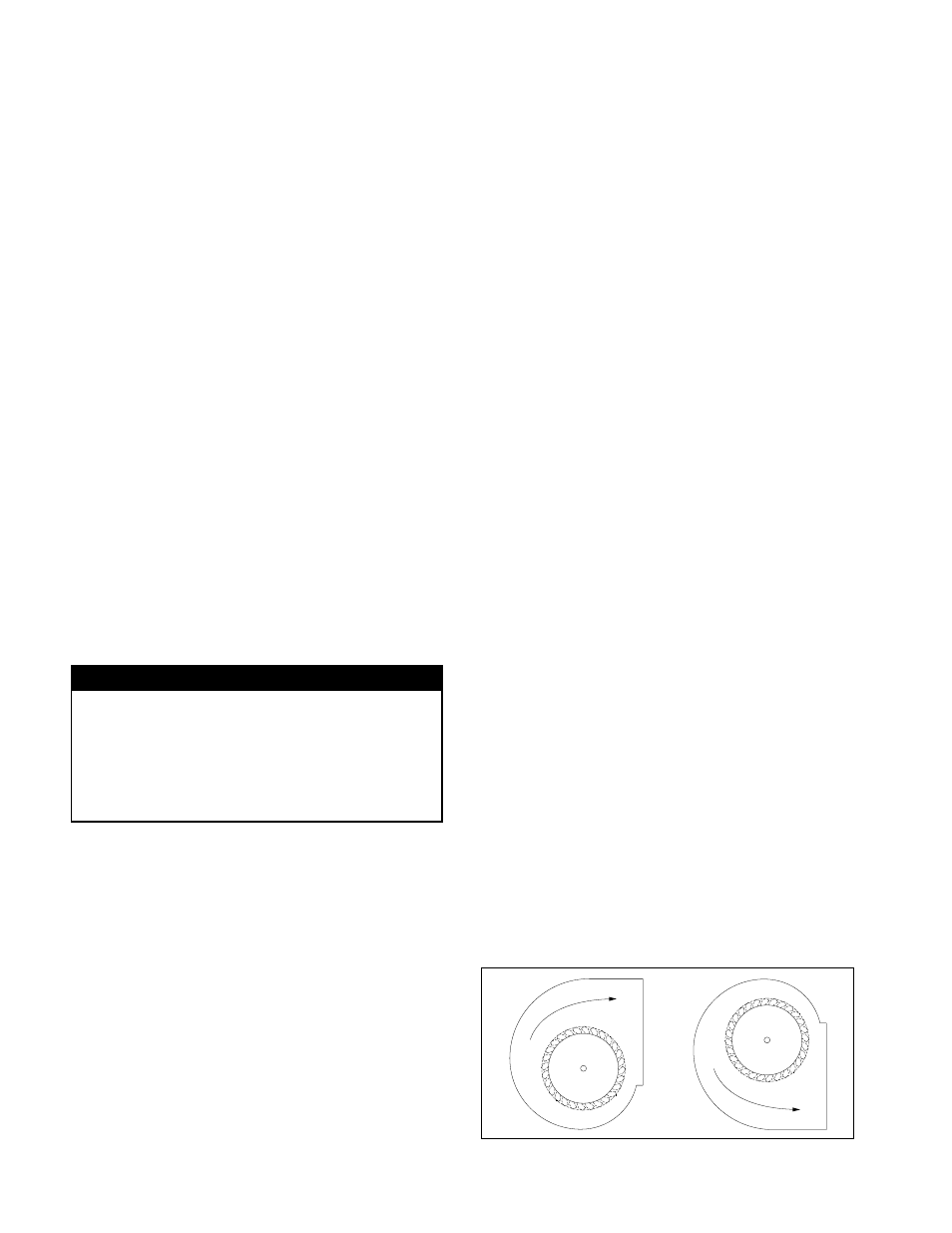

3. Apply power to unit and check rotation of wheel with

the directional arrow on the unit. See Figure 1.

WARNING: Rotation is critical. If allowed to operate

in the wrong direction, the motor will overload and

burn out.

WARNING: Check units for rotation. For three-phase,

rotation can be changed by interchanging any two of

the three line leads. If unit is checked on temporary

Figure 1. Fan Wheel Rotation

Electrical Connection

1. Connect supply wiring to the disconnect switch

(non-fused standard). Check the wiring diagrams on

the motor for connections.

2. The motor is factory set at the voltage marked on

the fan nameplate. Check the line voltage with the

nameplate voltage and wiring diagrams.

3. The main power wiring should be sized for the

ampacity shown on the dataplate. Size wires in

accordance with the ampacity tables in Article 310

of the National Electrical Code. If long wires are

required, it may be necessary to increase wire size

to prevent excessive voltage drop. Wires should be

sized for a maximum of 3% voltage drop.

CAUTION: Use copper conductors only.

CAUTION: Protect wiring from sharp edges. Leave

some slack in the line to prevent damage.

4. Disconnect switches are not fused. The power leads

must be protected at the point of distribution in

accordance with the fan dataplate.

5. On fans without a thermal protector integral to the

motor (refer to unit or motor dataplate to determine

if protector is present) a separate overload device

is required. Refer to Sections 430-32 of the N.E.C.

for sizing.

6. All units must be electrically grounded in accordance

with local codes or, in the absence of local codes,

with the latest edition of the National Electrical

Code (ANSI/NFPA 70). A ground lug is provided as

standard in the unit terminal box. Size grounding

conductor in accordance with Table 250-95 of the

National Electrical Code.

DO NOT use the ground

lug for connecting a neutral conductor.

7. Supply voltage to the inline fan should not vary by

more than 10% of the value indicated on the unit

dataplate. Phase unbalance must not exceed 2%.

WARNING: Failure of motor due to operation on

improper line voltage or with excessive phase unbal-

ance constitutes product abuse and may cause

severe damage to the unit’s electrical components.

wiring, it should be rechecked when permanently

installed. Motor burn-out or tripped overload protec-

tion devices are usually the result of wrong rotation.

4.

Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take into account the service factor range

if motor is nameplated above a 1.0 service factor.

5. Fan RPM should be checked and verified with a

tachometer.

NOTE: The fan was balanced at the factory to be

within stringent vibration levels before shipment.

However, there are several things that may cause

vibration, such as rough handling in shipment and

installation, weak foundations and alignments.

Rotation

Rotation