Operation check list, Maintenance of fans – Twin City Modular Plenum Fans - MPLFN / MPLFS / MPLQN / MPLQS - IM-495 User Manual

Page 4

4

Twin City IM-495

Operation Check List

Verify that proper safety precautions have been followed:

□.Electrical.power.must.be.locked.off.

Check fan mechanism components:

□ System.connections.are.properly.made.and.tightened..□

□ Bearings.are.properly.lubricated.

□ Wheel,.drives.and.fan.surfaces.are.clean.and.free...

..of.debris.

□ Rotate.the.impeller.by.hand.to.verify.it.has.not.shifted.

..in.transit.

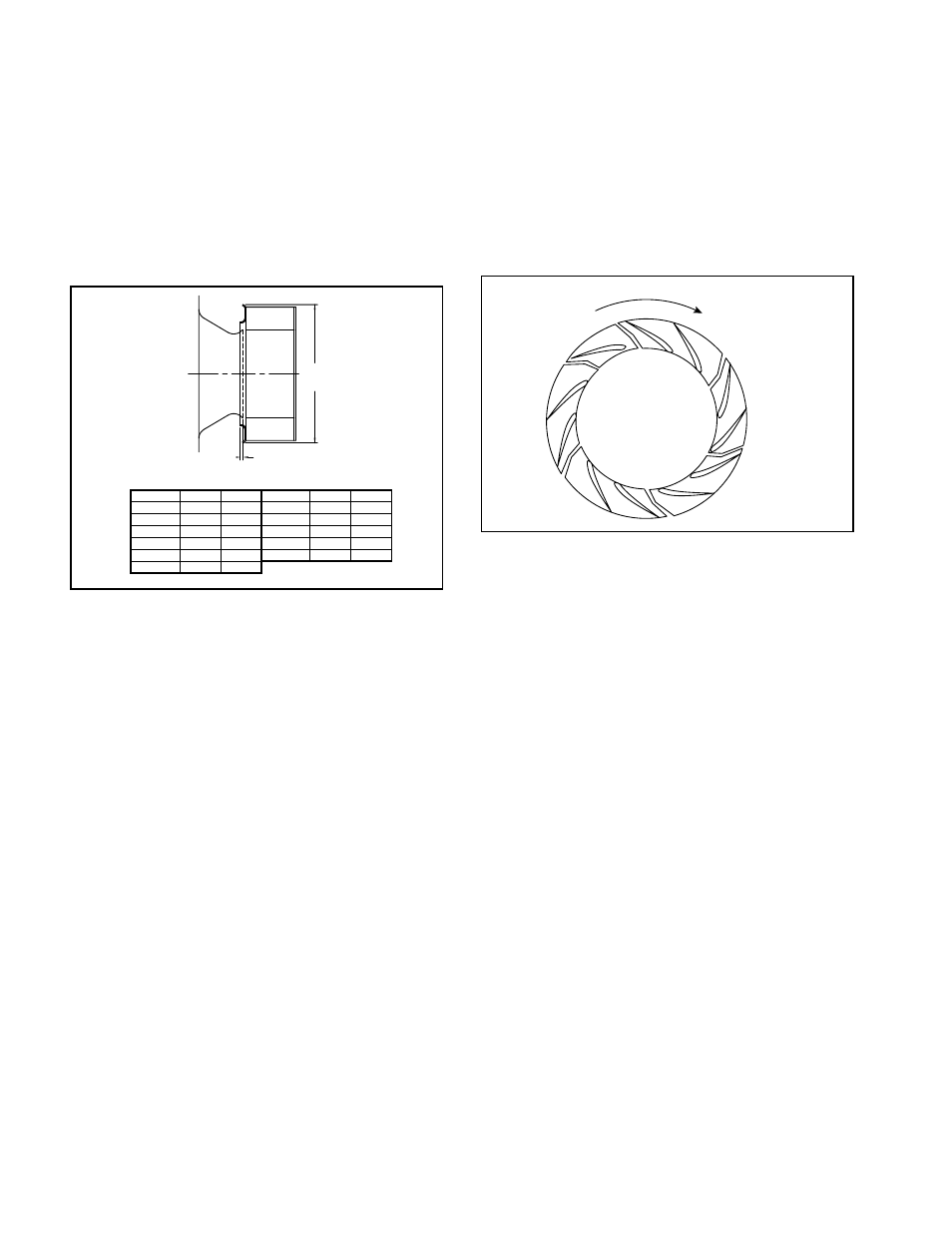

□ Check.fan/wheel.overlap..(See.Figure.4.)

Check fan electrical components:

□ Motor.is.wired.for.proper.supply.voltage.

□ Motor.was.properly.sized.for.power.and.rotational..

..inertia.of.rotating.assembly.

□ Motor.is.properly.grounded.

□ All.leads.are.properly.insulated.

Trial “bump”:

□ Turn.on.power.just.long.enough.to.start.assembly..

..rotating.

□ Check.rotation.for.agreement.with.rotation.arrow..

. Does. the. assembly. make. any. unusual. noise?..

..(See.Figure.5.)

□ Correct.any.problems.which.may.have.been.found..

..(Follow.safety.guidelines.-.shut.power.off.).Perform...

..checklist.again.until.unit.is.operating.properly.

□ Run.unit.up.to.speed.

Verify fastener tightness. These may have loosened dur-

ing shipment or installation.

□ Setscrews.attaching.wheel.hub.to.shaft.

□ Nuts.on.inlet.funnel.

□ Nuts.and.bolts.holding.motor.

□ Nuts.holding.housing.frame.to.base.and.base.to.

..ground.

□ Bolts.in.taper-lock.bushings.

□ Grease.line.connections.

After.one.week.of.operation,.check.all.nuts,.bolts.and.

setscrews.and.tighten.if.necessary.

Maintenance of Fans

This. section. contains. general. maintenance. instructions.

for.your.Twin.City.Fan.&.Blower.unit..For.specific.infor-

mation. about. maintenance. of. components,. particularly.

for.special.application.fans,.see.the.attached.documents.

General Motor Maintenance

The.three.basic.rules.of.motor.maintenance.are.keep.the.

motor.clean,.dry.and.properly.lubricated.

.

Keeping.motors.and.windings.clean.is.important.because.

dirt.and.dust.serve.as.thermal.insulators..Heat.normally.

dissipated. by. the. motor. is. trapped. causing. overheating.

and/or.premature.failure..Blow.dust.and.dirt.out.of.wind-

ings.and.off.the.motor.periodically..Use.low.pressure.(50.

psig).airstream.so.that.winding.damage.does.not.occur..

Keep.the.area.surrounding.the.motor.open.so.the.air.can.

circulate. through. the. motor. cooling. fan.. Follow. normal.

maintenance.schedule.given.to.the.right.

Motors.should.be.kept.dry.to.avoid.electrical.short.cir-

cuits.. Motors. kept. in. storage. for. long. periods. of. time.

can.have.moisture.condense.on.the.windings..Be.certain.

the.motor.is.dry.before.using.

Some.smaller.motors.are.lubricated.for.life..Motor.bear-

ing.lubrication,.if.required,.must.follow.a.rigorous.sched-

ule..Motors.less.than.10.hp.running.about.eight.hours.

a.day.in.a.clean.environment.should.be.lubricated.once.

every. five. years;. motors. 15. to. 50. hp,. every. 3. years;.

and.motors.50.to.150.hp,.yearly..For.motors.in.a.dusty.

or.dirty.environment.or.running.24.hours.a.day,.divide.

the.service.interval.by.2..If.the.environment.is.very.dirty.

or.high.temperatures.exist,.divide.the.service.interval.by.

4..Lubrication.requirements.are.normally.attached.to.the.

motor..Do.not.overlubricate.

.

A

DIA

B

Figure 4. Wheel-Funnel Overlap

Size

A

B

Size

A

B

122

12.75

0.130

245/245C

25.51

0.50

150

15.62

0.172

270/270C

28.11

0.55

165

17.18

0.203

300/300C

31.23

0.61

182/182C

19.00

0.38

330/330C

34.36

0.67

200/200C

20.82

0.41

365/365C

38.00

0.75

222/222C

23.16

0.45

MPLFN/MPLFS/MPLQN/MPLQS

MPLFN, MPLFS,

MPLQN, & MPLQS

Wheels

Rotation

Figure 5. Proper Wheel Rotation