Fan installation – factory assembled units, Assembly of fans, Electrical wiring of fans – Twin City Modular Plenum Fans - MPLFN / MPLFS / MPLQN / MPLQS - IM-495 User Manual

Page 3: Fan operation - safety

Twin City IM-495

3

Fan Installation – Factory Assembled Units

Follow.proper.handling.instructions.given.earlier.

1..Move.the.fan.to.the.final.mounting.position.

2..Remove.skid,.crates,.and.packing.materials.carefully.

3..If.supplied,.place.vibration.pads.or.isolation.base.on.

mounting.bolts..Line.up.holes.in.fan.base.with.bolts.

4..Place.fan.on.mounting.structure..Carefully.level.unit.

using. shims. as. required. at. all. mounting. hole. loca-

tions..Bolt.down.the.unit.

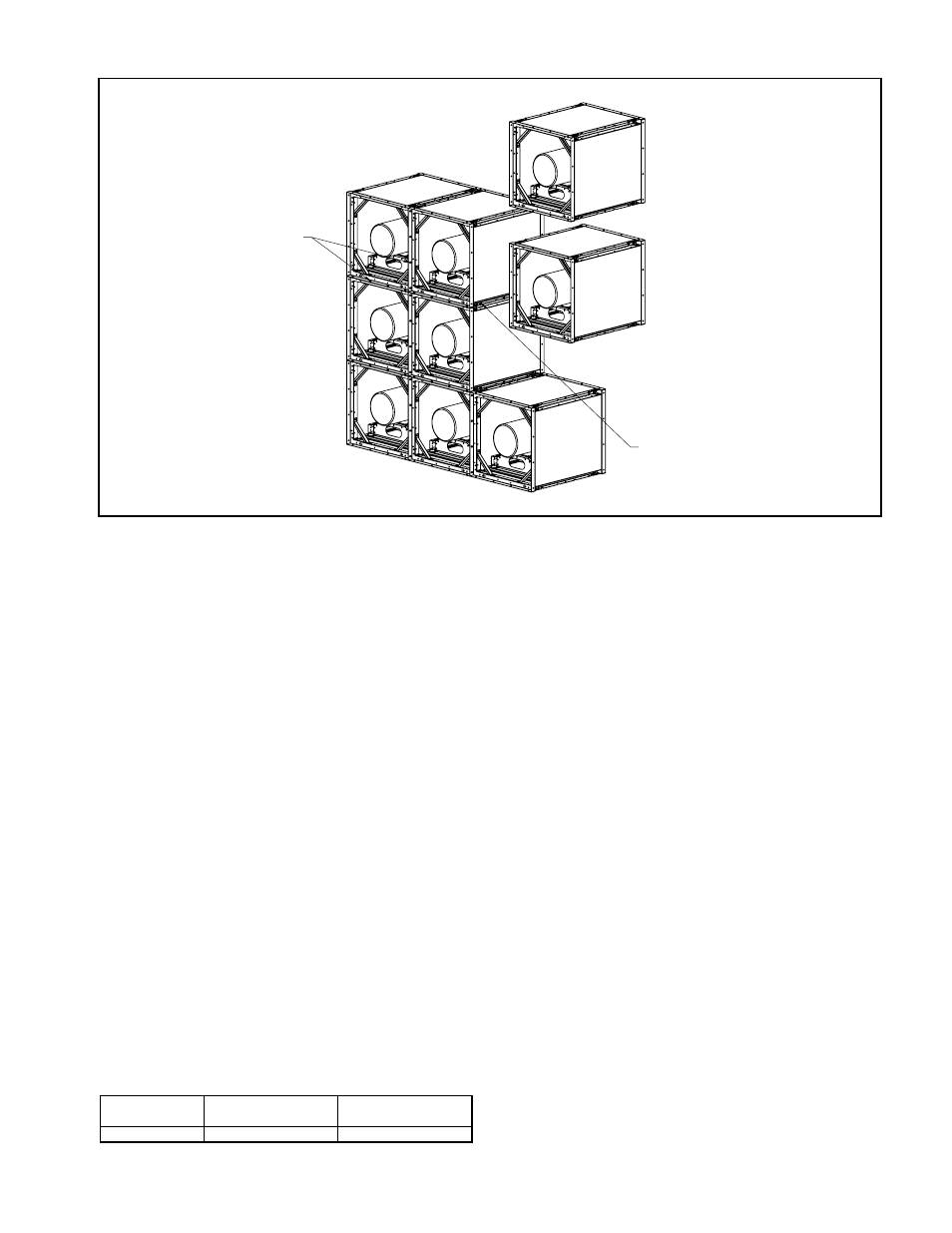

Assembly of Fans

1..Fans.must.be.securely.bolted.to.a.base.either.directly.

through.the.factory.mounting.holes.or.with.a.properly.

designed.clip..Final.bolting.of.each.individual.row.of.

fans.to.the.support.structure.or.base.should.be.done.

after.the.individual.fans.are.bolted.together.as.a.row.

.

NOTE: A.thin.gasket.or.caulk.may.be.used.to.prevent.

undesired.air.leakage.and.noise.

2..The.bolts.to.be.snugged.up.on.vertical.sections.for.the.

first.row..Once.all.fasteners.are.in.place,.the.bolts.shall.

be.tightened.to.torque.values.in.table..See.Table.1.

3..The.bolts.holding.the.fan.to.the.supporting.structure.

can.now.be.torqued.

4..The.second.row.and.succeeding.rows.can.be.installed.

using.the.same.assembly.steps.as.the.first.row.

5..Sealing.around.the.perimeter.should.be.accomplished.

using.a.flexible.material.

Electrical Wiring of Fans

The. customer. is. required. to. investigate. and. install.

equipment. in. compliance. with. all. local. electrical. and.

safety.codes.for.the.equipment.location..Twin.City.Fan.&.

Blower.requires.all.power.cabling.be.located.away.from.

the. rotating. impeller. and. fastened. to. the. inside. of. the.

fan.housing..Wiring.must.be.routed.away.from.the.motor.

to.reduce.potential.contact.with.hot.or.greasy.surfaces.

When. a. fan. is. supplied. with. an. outlet. damper,. wiring.

the. electrical. supply. to. the. motor. requires. routing. the.

supply.through.the.damper.housing.frame..Knockouts.of.

various.sizes.are.provided.in.the.damper.housing.frame.to.

accommodate.cable.connectors.or.raceway.(see.figure.3).

Fan Operation - Safety

For. general. safety. practices. for. air. moving. equipment,.

see.AMCA.Catalog.410.

.

Twin. City. Fan. &. Blower. has. many. safety. accessories.

available.. These. safety. devices. include. (but. are. not.

limited.to).inlet.and.discharge.screens..The.use,.abuse,.

or.non-use.of.safety.devices.is.the.responsibility.of.the.

purchaser.

.

Facility-related. safety. conditions. include. fan. accessibil-

ity.and.location..How.easily.can.non-service.personnel.

access. the. unit?. Is. the. fan. in. a. hazardous. duty. envi-

ronment?. Was. the. unit. ordered. for. this. duty?. Other.

concerns. must. also. be. addressed.. All. fans. should. be.

powered. through. switches. which. are. easily. accessible.

to.service.personnel.from.the.fan..Every.switch.should.

have.the.ability.to.be.“locked-off”.by.the.service.person.

and. the. key. to. be. retained. by. this. person. to. prevent.

accidental.power.of.the.fan.while.service.is.in.process.

Figure 2.

Table 1. Torque Values MPLFN/MPLFS/MPLQN/MPLQS

Fasteners

Size

Net Type

Torque Values

(ft lbs)

3/8.–.16.UNC

Nylock

16.–.17

3/8-16 x 0.75 Screws & Nuts

front and back flanges

3/8-16 x 0.75 Screws & Nuts

axial flanges where accessable