Fan installation – factory assembled units, Assembly of fans and sealing/isolation strips, Fan operation - safety – Twin City MPQN/MPQS Modular Plenum Fans - ES-110 User Manual

Page 3

3

Twin City Engineering Supplement ES-110

Fan Installation – Factory Assembled Units

Follow.proper.handling.instructions.given.earlier.

1..Move.the.fan.to.the.final.mounting.position.

2..Remove.skid,.crates,.and.packing.materials.carefully.

3..If.supplied,.place.vibration.pads.or.isolation.base.on.

mounting.bolts..Line.up.holes.in.fan.base.with.bolts.

4..Place.fan.on.mounting.structure..Carefully.level.unit.

using. shims. as. required. at. all. mounting. hole. loca-

tions..Bolt.down.the.unit.

Assembly of Fans and Sealing/Isolation

Strips

1..Fans.must.be.securely.bolted.to.a.base.either.directly.

through.the.factory.mounting.holes.or.with.a.properly.

designed. clip.. Final. bolting. of. layer. of. fans. to. the.

support. structure. or. base. should. be. done. after. the.

individual.fans.are.bolted.together.as.a.row.

2..During. installation. rubber. strips. need. to. be. installed.

between. each. fan.. Use. double-sided. foam. tape. to.

hold. strips. in. place. during. installation.. Two. (2). to.

three.(3).pieces.of.tape.can.be.used.as.needed.for.

this. purpose. (each. end. and. middle. of. rubber. strip)..

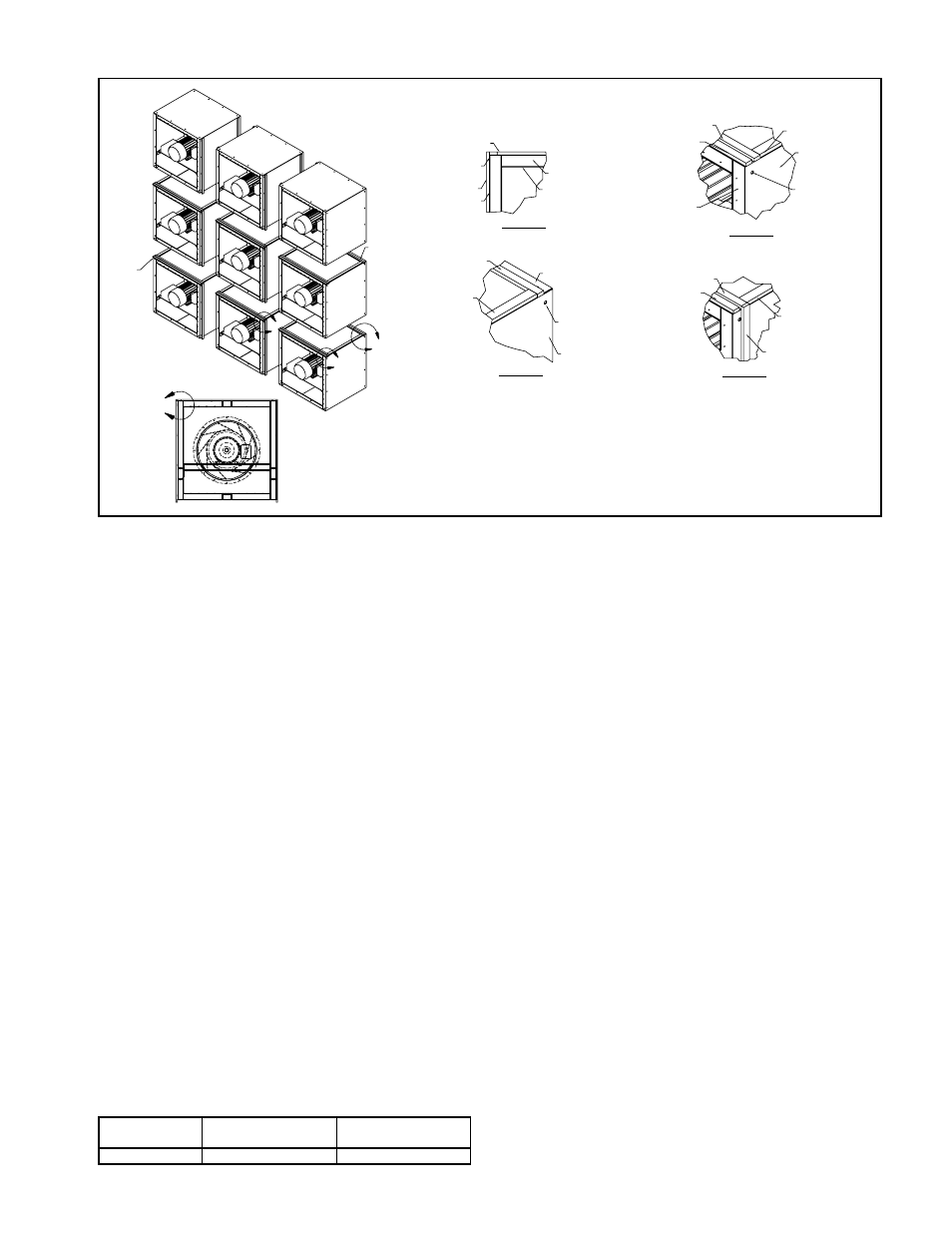

Location.of.these.strips.is.documented.in.Figure.2.

3..The.first.fan.on.the.bottom.row.will.have.the.2.verti-

cal. strips. placed. next. to. the. mounting. holes.. Note:.

Strips.should.be.cut.to.ensure.an.airtight.seal.between.

fans.

4..The.bolts.to.be.snugged.up.on.vertical.sections.for.the.

first.row..Once.all.strips.are.in.place,.the.bolts.shall.

be.tightened.to.torque.values.in.table..See.Table.1.

5..The.bolts.holding.the.fan.to.the.supporting.structure.

can.now.be.torqued.

6..Rubber.strips.are.then.placed.on.the.top.of.the.fan.

to.support.the.fan.above.it.according.to.the.pattern.

shown.. Note:. On. larger. fan. assemblies. 2. strips. are.

used.in.the.back.to.support.the.weight.of.the.motor.

7..The.second.row.and.succeeding.rows.can.be.installed.

using.the.same.assembly.steps.as.the.first.row.

8..Rubber.strips.are.not.normally.needed.on.the.outside.

or.top.of.the.parralel.fan.system.

9..Sealing.around.the.perimeter.should.be.accomplished.

using.a.flexible.material.

Fan Operation - Safety

For. general. safety. practices. for. air. moving. equipment,.

see.AMCA.Bulletin.410.

. Twin. City. Fan. &. Blower. has. many. safety. accesso-

ries.available..These.safety.devices.include.(but.are.not.

limited.to).inlet.and.discharge.screens..The.use,.abuse,.

or.non-use.of.safety.devices.is.the.responsibility.of.the.

purchaser.

. Facility-related. safety. conditions. include. fan. acces-

sibility.and.location..How.easily.can.non-service.person-

nel. access. the. unit?. Is. the. fan. in. a. hazardous. duty.

environment?.Was.the.unit.ordered.for.this.duty?.Other.

concerns. must. also. be. addressed.. All. fans. should. be.

powered.through.switches.which.are.easily.accessible.to.

service.personnel.from.the.fan..Every.switch.should.have.

the.ability.to.be.“locked-off”.by.the.service.person.and.

the.key.to.be.retained.by.this.person.to.prevent.acci-

dental.power.of.the.fan.while.service.is.in.process.

Figure 2.

MOUNTING HOLE

OUTER SHELL

RUBBER GASKET

RUBBER GASKET

OUTLET ONLY

222 & ABOVE

FRAME

FRAME

PERF. PLATE

RUBBER GASKET

RUBBER GASKET

RUBBER GASKET

RUBBER GASKET

RUBBER GASKET

RUBBER GASKET

NOTE 5

OUTER SHELL

RUBBER GASKET

RUBBER GASKET

OUTER SHELL

OUTER SHELL

MOUNTING HOLE

DETAIL C

DETAIL A

DETAIL D

DETAIL B

A

NOTES

RUBBER GASKET

D

B

C

NOTES:

1. On the horizontal between fans, one strip of gasket material is needed on inlet side & two

on drive end on 222 & above, 200 and below get one strip on each end.

2. Gaskets need to connect in all corners to ensure proper sealing.

3. Rubber gasket is to be placed directly next to the mounting holes on the inlet and drive side.

4. Rubber gasket is 1/2 in. x 2 in. x cut-to-fit.

5. Rubber gasket is to be held in place be double-stick foam tape during assembly.

RUBBER GASKET

Table 1. Torque Values MPQN/MPQS Fasteners

Size

Net Type

Torque Values

(ft lbs)

3/8.–.16.UNC

Nylock

16.–.17