Lubrication, Warning – Twin City Centrifugal Fans - ES-52 User Manual

Page 6

6

Twin City Engineering Supplement ES-52

. Bearing. failure. can. occur. from. many. causes.. See.

Troubleshooting.section.for.details.

Note:.All.speeds.shown.do.not.apply.to.all.shaft.sizes.

in.that.group..Consult.the.factory.if.in.doubt.of.maxi-

mum.speed.for.a.particular.bearing.

Lubrication

Proper. lubrication. of. bearings. helps. assure. maximum.

bearing.life..All.fans.are.equipped.with.decals.indicating.

relubrication. intervals. for. normal. operating. conditions..

However,.every.installation.is.different.and.the.frequency.

of.lubrication.should.be.established.accordingly.

. Experience. has. shown. that. airborne. moisture. and.

heavy.dust.will.dramatically.reduce.the.life.of.the.bearing.

lubricant..If.any.of.these.adverse.conditions.exist,.it.is.

recommended. that. bearings. be. regreased. after. several.

days. of. operation.. Lubrication. intervals. can. then. be.

adjusted.based.on.the.condition.of.the.purged.grease.

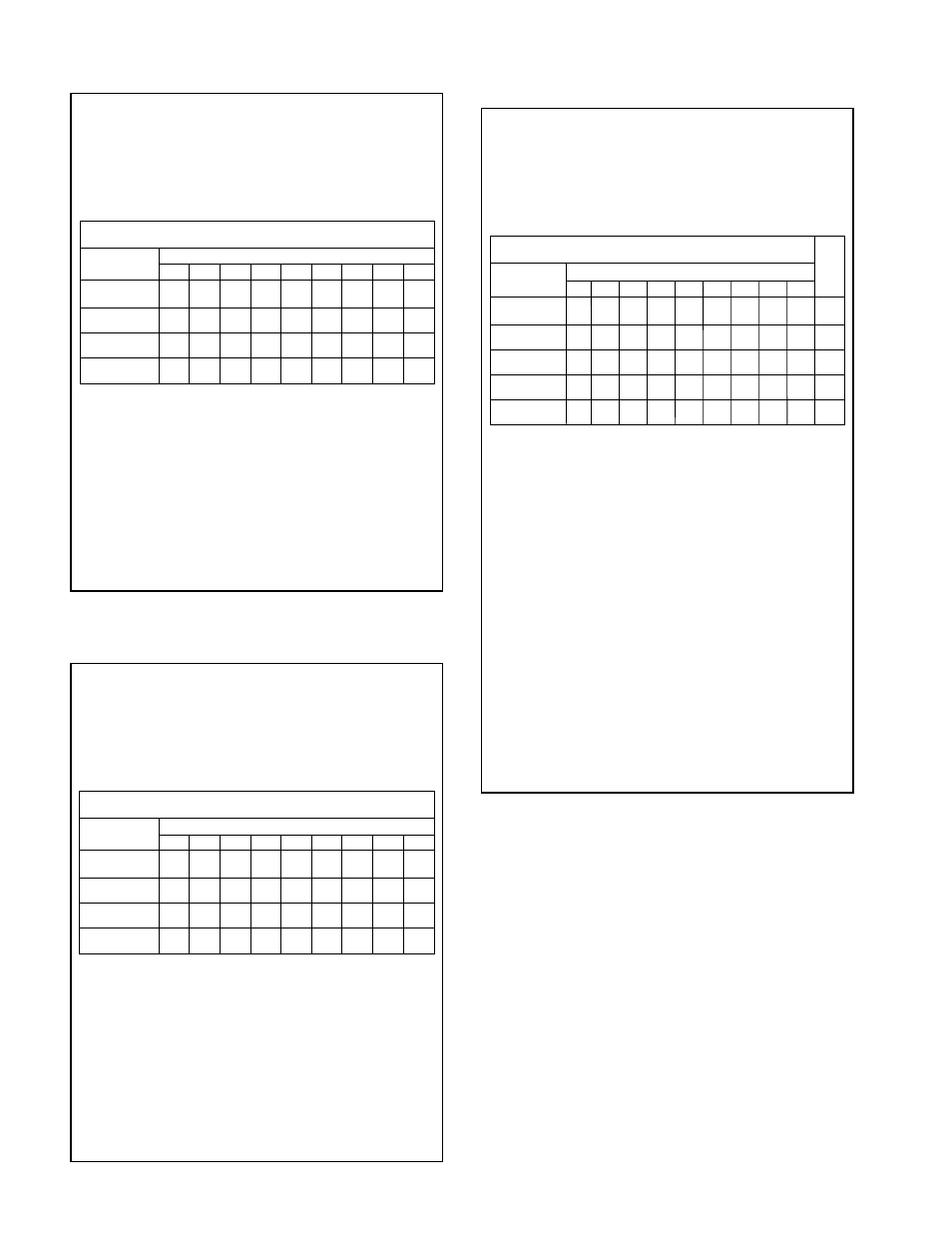

. Figure.9.illustrates.the.decal.for.ball.bearings,.Figure.

10.the.decal.for.solid.pillow.block.spherical.roller.bear-

ings,.and.Figure.11.shows.the.decal.for.spherical.roller.

Figure 11. Safety & Lubrication Instructions for Fans

with Spherical Roller Bearings with Split Pillow

Block Housings

WARNING

1.. This.equipment.must.not.be.operated.without.proper.guarding.of.

all. moving. parts.. While. performing. maintenance. be. sure. remote.

power.switches.are.locked.off..See.installation.manual.for.recom-

mended.safety.practices.

2.. Before.starting:.Check.all.setscrews.for.tightness,.and.rotate.wheel.

by.hand.to.make.sure.it.has.not.moved.in.transit.

*Suggested.lubrication.interval.under.ideal.continuous.operating.condi-

tions..Remove.bearing.cap.and.observe.condition.of.used.grease.after.

lubricating.. Adjust. lubrication. frequency. as. needed.. Use. one-half. of.

listed.interval.for.vertical.shaft.applications.or.for.24.hour.operation...

Hours.of.operation,.temperature,.and.surrounding.conditions.will.affect.

the.relubrication.frequency.required..Clean.and.repack.bearings.annu-

ally..Remove.old.grease,.pack.bearing.full.and.fill.housing.reservoir.

on.both.sides.of.bearings.to.bottom.of.shaft........................................................

1.. Lubricate.with.a.high.quality.NLGI.No..2.lithium-base.grease.hav-

ing. rust. inhibitors. and. antioxidant. additives,. and. a. minimum. oil.

viscosity.of.500.SUS.at.100°F.(38°C)..Some.greases.having.these.

properties.are:

.

Shell.-.Gadus.S2.V100.2.

Exxon.-.Ronex.MP.

Mobil.-.Mobilith.SHC100.

Mobil.-.Mobilith.SHC220

2.. Lubricate. bearings. prior. to. extended. shutdown. or. storage. and.

rotate.shaft.monthly.to.aid.corrosion.protection.

3.. Purge.or.remove.old.grease.when.changing.lubrication.brands.or.

types.

Static Oil Lubrication

1.. Use.only.high.quality.mineral.oil.with.a.VG.grade.indicated.on.the.

customer.submittal.drawing..

2.. Static. oil. level. should. be. at. the. center. of. the. lower-most. roller.

(Do.not.overfill.)

3.. Complete.lubrication.change.should.be.made.annually.

Relubrication Schedule (Months)*

Spherical Roller Bearing - Split Pillow Blocks

Speed (RPM)

Shaft DIA

500

750 1000 1500 2000 2500 3000 3500 4000

1

7

⁄

16

" thru 1

15

⁄

16

".

6.

4

1

⁄

2

.

4.

4.

3

1

⁄

2

. 2

1

⁄

2

. 2

1

⁄

2

.

1.

1. 0.50.oz.

...

(35 – 50)

2

3

⁄

16

" thru 2

13

⁄

16

".

5.

4

1

⁄

2

.

4.

2

1

⁄

2

. 2

1

⁄

2

. 1

1

⁄

2

.

1

⁄

2

.

1

⁄

4

.

1

⁄

4

. 0.75.oz.

...

(55 – 70)

2

15

⁄

16

" thru 3

15

⁄

16

".

4

1

⁄

2

.

4.

3

1

⁄

2

. 2

1

⁄

2

. 1

1

⁄

2

.

1.

1

⁄

2

.

.

. 2.00.oz.

...

(75 – 100)

4

7

⁄

16

" thru 4

15

⁄

16

".

4.

4.

2

1

⁄

2

.

1.

..

1

⁄

2

.

.

.

.

. 4.00.oz.

..

(110 – 135)

5

7

⁄

16

" thru 6

15

⁄

16

".

4.

2

1

⁄

2

. 1

1

⁄

2

.

.

.

.

.

.

. 7.00.oz.

..

(140 – 180)

Grease

to be

added

at each

interval

WARNING

1.. This.equipment.must.not.be.operated.without.proper.guarding.of.

all. moving. parts.. While. performing. maintenance. be. sure. remote.

power.switches.are.locked.off..See.installation.manual.for.recom-

mended.safety.practices.

2.. Before.starting:.Check.all.setscrews.for.tightness.and.rotate.wheel.

by.hand.to.make.sure.it.has.not.moved.in.transit.

*Suggested.lubrication.interval.under.ideal.continuous.operating.condi-

tions..Relubricate.while.running,.if.safety.permits,.until.some.purging.

occurs.at.seals..Adjust.lubrication.frequency.depending.on.conditions.

of.purged.grease..Use.one-half.of.listed.interval.for.vertical.shaft.appli-

cations.or.for.24.hour.operation..Hours.of.operation,.temperature,.and.

surrounding.conditions.will.affect.the.relubrication.frequency.required...

1.. Lubricate.with.a.high.quality.NLGI.No..2.lithium-base.grease.hav-

ing. rust. inhibitors. and. antioxidant. additives,. and. a. minimum. oil.

viscosity.of.500.SUS.at.100°F.(38°C)..Some.greases.having.these.

properties.are:

.

Shell.-.Gadus.S2.V100.2.

Exxon.-.Ronex.MP.

Mobil.-.Mobilith.SHC100.

Mobil.-.Mobilith.SHC220

2.. Lubricate. bearings. prior. to. extended. shutdown. or. storage. and.

rotate.shaft.monthly.to.aid.corrosion.protection.

Relubrication Schedule (Months)*

Spherical Roller Bearing - Solid Pillow Blocks

Speed (RPM)

Shaft DIA

500 1000 1500 2000 2500 3000 3500 4000 4500

1" thru 1

7

⁄

16

"

6

4

4

2

1

1

1

1

1

⁄

2

...

(25 – 35)

1

11

⁄

16

" thru 2

3

⁄

16

"

4

2

1

1

⁄

2

1

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

...

(40 – 55)

2

7

⁄

16

" thru 3

7

⁄

16

"

3

1

1

⁄

2

1

1

⁄

2

1

⁄

2

1

⁄

4

1

⁄

4

...

(60 – 85)

3

15

⁄

16

" thru 4

15

⁄

16

"

2

1

⁄

2

1

1

⁄

2

1

⁄

4

...

(90 – 125)

Figure 10. Safety & Lubrication Instructions for Fans

with Unit Roller Bearings

WARNING

1.. This.equipment.must.not.be.operated.without.proper.guarding.of.

all. moving. parts.. While. performing. maintenance. be. sure. remote.

power.switches.are.locked.off..See.installation.manual.for.recom-

mended.safety.practices.

2.. Before.starting:.Check.all.setscrews.for.tightness.and.rotate.wheel.

by.hand.to.make.sure.it.has.not.moved.in.transit.

*.Suggested.lubrication.interval.under.ideal.continuous.operating.con-

ditions..Relubricate.while.running,.if.safety.permits,.until.some.purging.

occurs.at.seals..Adjust.lubrication.frequency.depending.on.conditions.

of.purged.grease..Use.one-half.of.listed.interval.for.vertical.shaft.appli-

cations.or.for.24.hour.operation..Hours.of.operation,.temperature,.and.

surrounding.conditions.will.affect.the.relubrication.frequency.required.

1.. Lubricate.with.a.high.quality.NLGI.No..2.lithium-base.grease.hav-

ing. rust. inhibitors. and. antioxidant. additives,. and. a. minimum. oil.

viscosity.of.500.SUS.at.100°F.(38°C)..Some.greases.having.these.

properties.are:

.

Shell.-.Gadus.S2.V100.2.

Exxon.-.Ronex.MP.

Mobil.-.Mobilith.SHC100.

Mobil.-.Mobilith.SHC220

2.. Lubricate. bearings. prior. to. extended. shutdown. or. storage. and.

rotate.shaft.monthly.to.aid.corrosion.protection.

Figure 9. Safety & Lubrication Instructions for Fans

with Ball Bearings

Relubrication Schedule (Months)*

Ball Bearing Pillow Blocks

Speed (RPM)

Shaft DIA

500 1000 1500 2000 2500 3000 3500 4000 4500

1

⁄

2

" thru 1

11

⁄

16

".

6.

6.

5.

3.

3.

2.

2.

2.

1

....

(13 – 45)

1

15

⁄

16

" thru 2

7

⁄

16

".

6.

5.

4.

2.

2.

1.

1.

1.

1

....

(50 – 60)

2

11

⁄

16

" thru 2

15

⁄

16

".

5.

4.

3.

2.

1.

1.

1.

....

(65 – 75)

3

7

⁄

16

" thru 3

15

⁄

16

".

4.

3.

2.

1.

1

...

(80 – 100)