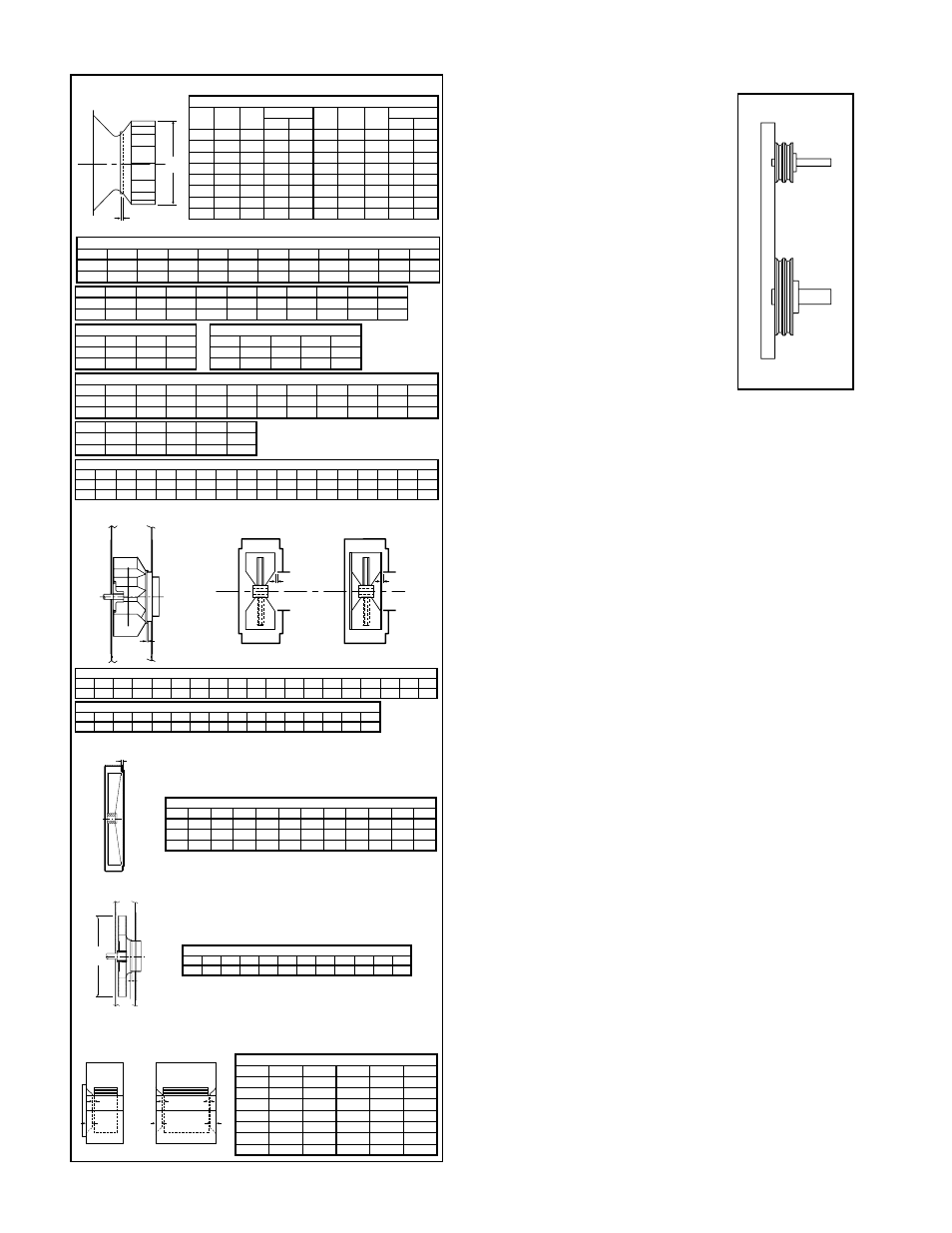

Fan operation - safety, 4twin city engineering supplement es-52, Figure 7. wheel-funnel overlap – Twin City Centrifugal Fans - ES-52 User Manual

Page 4: Figure 6. sheave alignment

4

Twin City Engineering Supplement ES-52

.

RBO, RBR Wheel Placement

Size 913 915 917 919 921 923 926 929 933 937 941 945 949 954 960

B

0.53 0.53 0.59 0.69 0.78 0.88 0.97 1.03 1.22 1.38 1.56 1.69 1.81 1.88 2.16

the. key. should. be. placed. in.

the.keyway.pushed.toward.the.

bearing. as. far. as. the. runout.

will. allow. without. rubbing.. The.

back. of. the. sheave. should. be.

lined. up. with. the. end. of. the.

key. (see. Figure. 5. on. page. 3)..

For.sheaves.without.a.key,.the.

sheave. should. be. placed. as.

close. to. motor. and/or. bearing.

as. possible. without. rubbing..

Typically. the. sheave. should.

be. at. least. ¼". away. from. the.

motor,. bearing,. guard,. struc-

tures,.etc.

c..Align. sheaves. with. a. straight-

edge.extended.along.the.perim-

eters. of. both. sheaves,. just.

making. contact. in. two. places.

on. outside. perimeters. of. both.

sheaves.(see.Figure.6).

d..Tighten.down.sheave.bolts.

e..Install.a.matched.set.of.belts..Slide.the.motor.to.

obtain. slack. and. tighten. belts.. Using. a. pry. will.

damage.belts.

f... Tighten.belts.to.proper.belt.tension..Ideal.tension.

is. just. enough. tension. so. that. belts. do. not. slip.

under.peak.load..Recheck.sheave.alignment.

g..After.initial.installation.of.belts,.recheck.belt.tension.

again.after.a.few.days.to.adjust.belt.tension..(New.

belts.require.a.break-in.period.of.operation.)

10..Install. any. safety. devices. or. accessories. supplied..

(Accessories. commonly. used. are. inlet. vanes,. shaft.

seals.and.shaft.coolers,.plugs,.dampers,.and.inlet.or.

discharge.screens..Refer.to.appropriate.documents.

in.appendix.)

11..Grout. may. now. be. applied.. Grout. is. used. to. dis-

tribute.loads.and.should..not.be.used.as.the.sole.

support.of.any.rotating.equipment.

12..When.connecting.the.fan.to.the.system,.it.is.recom-

mended.that.the.inlet.and.discharge.be.isolated.from.

the.system.with.flex.connections.(where.practical).to.

block. transmitted. vibration.. All. duct. connections. to.

the.fan.should.be.independently.supported..Do.not.

use.fan.to.support.duct.

Fan Operation - Safety

For. general. safety. practices. for. air. moving. equipment,.

see.AMCA.Bulletin.410.

. Twin. City. Fan. &. Blower. has. many. safety. accesso-

ries.available..These.safety.devices.include.(but.are.not.

limited.to).belt.guards,.shaft.guards,.inlet.and.discharge.

screens..The.use,.abuse,.or.non-use.of.safety.devices.

is.the.responsibility.of.the.purchaser.

. Facility-related. safety. conditions. include. fan. acces-

sibility.and.location..How.easily.can.non-service.person-

nel. access. the. unit?. Is. the. fan. in. a. hazardous. duty.

environment?.Was.the.unit.ordered.for.this.duty?.Other.

concerns. must. also. be. addressed.. All. fans. should. be.

powered. through. switches. which. are. easily. accessible.

to.service.personnel.from.the.fan..Every.switch.should.

have.the.ability.to.be.“locked-off”.by.the.service.person.

and. the. key. to. be. retained. by. this. person. to. prevent.

accidental.power.of.the.fan.while.service.is.in.process.

A

DIA

B

RBO

RBR

B

B

B

A

B

A

B

A

SWSI

DWDI

Figure 7. Wheel-Funnel Overlap

HIB, RTF, HRT* Wheel Placement

Size

A

B

B*

Size

A

B

B*

19

23

19

23

180 20.50 0.31

—

.—

400 45.25 0.69 1.03 0.97

200 22.50 0.34

—

—

450 50.00 0.75 1.13 1.06

220 25.00 0.38

—

—

490 55.13 0.81 1.25 1.13

240 27.50 0.44

—

—

540 61.00 0.91 1.38 1.25

270 30.38 0.47 0.50 0.50 600 67.50 1.00 1.31 1.31

300 33.50 0.50 0.69 0.69 660 74.25 1.13 1.56 1.44

330 37.00 0.56 0.69 0.69 730 82.00 1.22 1.75 1.63

360 41.00 0.63 0.81 0.81 800 90.75 1.34 1.06 1.31

HIB, RTF, HRT, BC, BCS, TSL, BAF, BAE, EPF & EPQ

BC-SW, BC-DW, BCS, TSL, BAF SWSI & DWDI Wheel Placement

Size

122

135

150

165

182

200

222

245

270

300

330

A

12.25 13.50 15.00 16.50 18.25 20.00 22.25 24.50 27.00 30.00 33.00

B

0.32

0.34

0.38

0.44

0.56

0.63

0.69

0.75

0.88

0.97

1.06

RBA, RBO & RBR

FC

Size

365

402

445

490

542

600

660

730

807

890

A

36.50 40.25 44.50 49.00 54.25 60.00 66.00 73.00 80.75 89.00

B

0.94

1.03

1.13

1.25

1.38

1.56

1.69

1.88

2.09

2.28

EPF, EPQ, BAE SWSI & DWDI Wheel Placement

Size

182

200

222

245

270

300

330

365

402

445

490

A

19.00 20.82 23.16 25.51 28.11 31.23 34.36 38.00 41.90 46.33 51.01

B

0.38

0.41

0.46

0.50

0.55

0.62

0.68

0.75

0.83

0.91

1.01

Size

542

600

660

730

807

A

56.48 62.47 68.71 76.00 84.07

B

1.11

1.23

1.36

1.50

1.66

EPF, EPQ Wheel Placement

Size

122

150

165

A

13.00 14.13 16.16

B

0.25

0.25

0.25

BAE SWSI & DWDI Wheel Placement

Size

122

135

150

165

A

12.25 13.50 15.00 16.50

B

0.31

0.34

0.38

0.44

A

RBA

RBA Wheel Placement

Size 907 909 911 913 915 917 919 921 923 926 929 933 937 941 945 949 954 960

A

0.25 0.38 0.47 0.53 0.59 0.69 0.69 0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

MBW, MBO & MBR

MBW, MBO, MBR Wheel Placement

Size 196

224

252

280

308

336

365

421

477

533

589

MBW 0.50 0.44 0.38 0.25 0.38 0.44 0.56 0.63 0.75 0.75 0.88

MBO 0.50 0.44 0.38 0.25 0.38 0.44 0.56 0.63 0.75 0.75 0.88

MBR 0.25 0.25 0.25 0.25 0.25 0.38 0.50 0.69 0.81 0.94 1.00

GAP

FC Wheel Placement

Size

A

B

Size

A

B

10.5

0.47

0.69

30

0.75

4.38

12

0.25

1.88

33

0.81

5.00

15

0.44

2.19

36

0.75

5.00

18

0.50

2.25

39

1.06

6.38

21

0.69

2.88

42

1.69

7.50

24

0.81

3.00

48

1.50

7.13

27

0.69

3.13

54

1.00

10.50

B

A

Dia.

BCN Wheel Placement

Size 270 300 330 365 402 445 490 542 600 660 730

B

0.09 0.09 0.13 0.13 0.13 0.16 0.16 0.19 0.22 0.22 0.25

BCN

APF & APQ Wheel Placement

Size 121

141

161

181

201

221

251

281

321

351

391

441

491

551

631

711

791

A

13.00 14.13 16.16 18.44 19.94 22.78 25.06 28.25 31.81 35.81 39.81 44.56 50.06 55.75 63.69 71.69 79.63

B

0.25 0.25 0.25 0.31 0.31 0.31 0.50 0.50 0.56 0.63 0.63 0.75 0.78 0.81 1.03 1.28 1.38

Note:.On.sizes.905-911.wheel.is.to.be.centered.in.housing.

*Use.second.'B'.columns.for.HRT-19.and.HRT-23.dimensions

Note:.On.sizes.421-589.wheel.is.to.be.centered.in.housing.

Figure 6.

Sheave Alignment