Electrical pin-out – TruTrak EFIS AP (8300-057C) User Manual

Page 22

TruTrak Flight Systems

20

EFIS Autopilot Installation Manual

April 2009

8300-057 Rev D

Electrical Pin-out

EFIS with Yaw Damper will be covered in this manual.

The table below provides a brief explanation of each pin function on the main 37-pin connector P101.

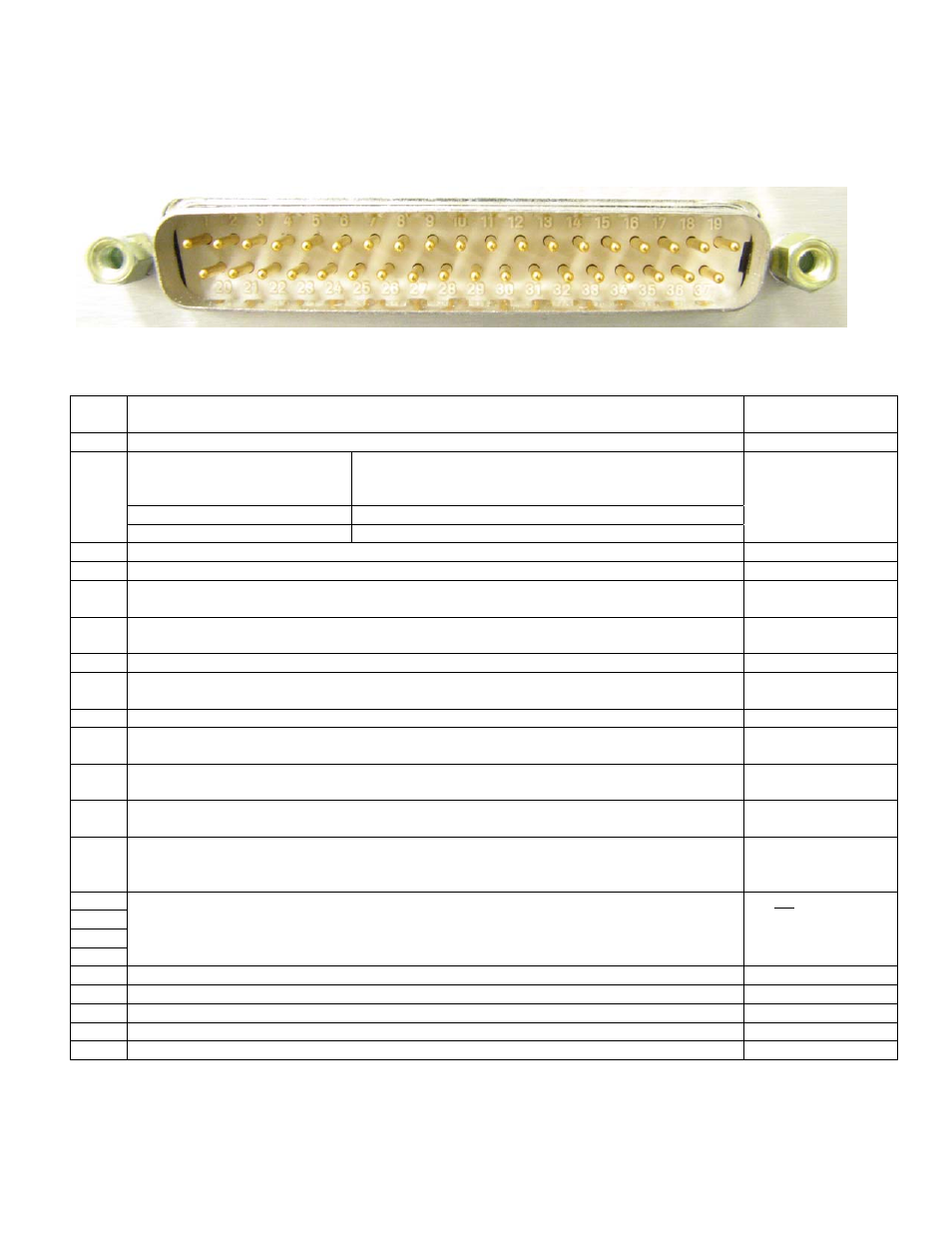

P101 Autopilot Rear Connector (Viewed from rear of autopilot) or wire side of connector.

P101

Pin

Function

Notes

1 Dedicated ground connection for Pitch Reverse Jumper.

Pitch Reverse Jumper,

present or absent, as follows:

Direction of servo arm / capstan rotation

(as viewed from face of the servo body)

for UP elevator

Pin 2 open (no connect):

Servo CCW (counter-clockwise) Î UP

2

Pin 2 Jumper to pin 1:

Servo CW (clockwise) Î UP

3 NAV / TT Converter box RS-232 Output.

SL-30 NAV pin 4 RX

4 Dimmer

connection

5 Yaw Damper Activity. A signal from the autopilot which sets the amount of response the yaw

damper exhibits to azimuth disturbances and “ball” deflection.

EFIS with Yaw

Damper only

6 Yaw Damper Centering. A signal from the autopilot which is used for fine adjustment of the

“ball” in a yaw damper.

EFIS with Yaw

Damper only

7 AP illumination, To AP LEVEL Button lamp

8 Yaw Damper Activate. A signal from the autopilot which turns on the yaw damper function.

EFIS with Yaw

Damper only

9 No

Connection

10 Pitch Servo Torque Control. A signal from the autopilot to the pitch servo which sets the

amount of torque to be delivered by the servo.

11 Pitch Servo Trim Sensor. A signal from the pitch servo to the autopilot which indicates an

out-of-trim condition and its direction.

12 Autopilot Master (+12 to +28 V DC). The autopilot itself draws less than 3 ampere. Most of

the current required by the autopilot system is used by the servos (up to 1.5A per servo).

13 Audio signal Out. This pin may be wired to an unswitched input of an audio panel. The

autopilot uses various voice or tones to denote specific events (loss of GPSS, capture

Glideslope, etc). Volume is adjustable within a setup screen of the autopilot.

14

15

16

17

Pitch Servo control lines. These lines cause the stepping motor in the pitch servo to run in the

appropriate direction at the desired velocity. They are small-signal lines and do not have any

substantial current-carrying capability or require any special shielding. Connect to pitch servo

as shown on wiring diagram.

Do not attempt to

reverse servo

direction by

swapping wires

18 Future

Use

Unavailable at this time

19 Power Ground Connection. Provide #20 AWG to common grounding point.

20 CWS / AP LEVEL Button.

21 EMS

switch

Switch to ground

22 NO

CONNECTION