Top Flite TOPA0906 User Manual

Page 19

19

lock pushrod connector and position it so that the

forward end protrudes approximately 3/8" [9.5mm]

beyond the connector. Align the nose gear so that

the wheel is pointing straight ahead. With the rudder

in the neutral position, mark where the pushrod

crosses the second inner hole in the remaining

rudder servo arm. Remove the pushrod from the

tube, make a 90° bend at the mark on the pushrod

and cut off the excess pushrod 1/4" [6mm] beyond

the bend. Reinstall the pushrod into the tube and

fit the forward end through the screw-lock pushrod

connector. Attach the pushrod to the servo arm

using a nylon FasLink. Make any fine adjustments

necessary. Then, tighten the SHCS in the screw-lock

pushrod connector against the pushrod.

o

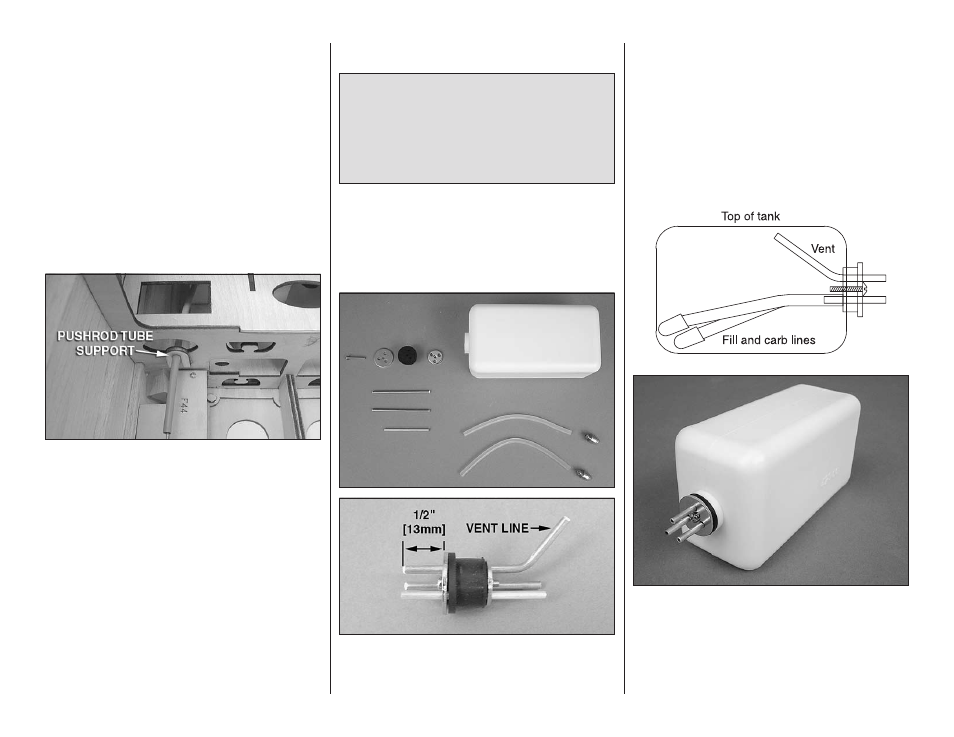

11. Use a plywood

pushrod tube support to

secure the steering pushrod tube to the third former.

Glue the outer pushrod tube to the support and glue

the support to the third former as shown.

INSTALL THE POWER SYSTEM

The following sections contain detailed instructions

for mounting an O.S. .61 FX two-stroke glow engine

and the Great Planes RimFire 1.20 (50-65-450kV)

out-runner brushless motor. Each specific installation

only contains information relevant to that particular

power system so you can skip directly to the section

that matches your choice of power systems.

GLOW ENGINE INSTALLATION

The installation of a brand of glow engine other

than the O.S. .61 FX should be similar to the

procedure listed below for the O.S. model.

o

1. The fuel tank can be assembled as a two line

system consisting of a vent (pressure) line to the

muffler and a carb line. Filling and emptying of the

tank would need to be done through the carb line, or

an optional fuel fill valve (not included). The tank can

also be assembled as a three line system having a

vent line, carb line, and fill line. If installing a fill line,

puncture the top of the stopper above the sealed off

fuel tube hole. The fill and carb lines should extend

out 1/2" [13mm] beyond the stopper and the vent line

should be bent upwards and left uncut. With the tubes

installed in the stopper, fit the stopper plates loosely

in place with the 3 x 25mm Phillips screw to hold the

assembly together.

o

2. Fit the stopper assembly into the tank with the

vent line pointing toward the top of the tank, but not

touching. The fuel tubing and clunks (fuel pickup) on

the carb and fill lines should almost reach the back

of the tank but not touch. The clunks must be able

to move freely inside the tank when assembled.