Top Flite TOPA0906 User Manual

Page 16

o

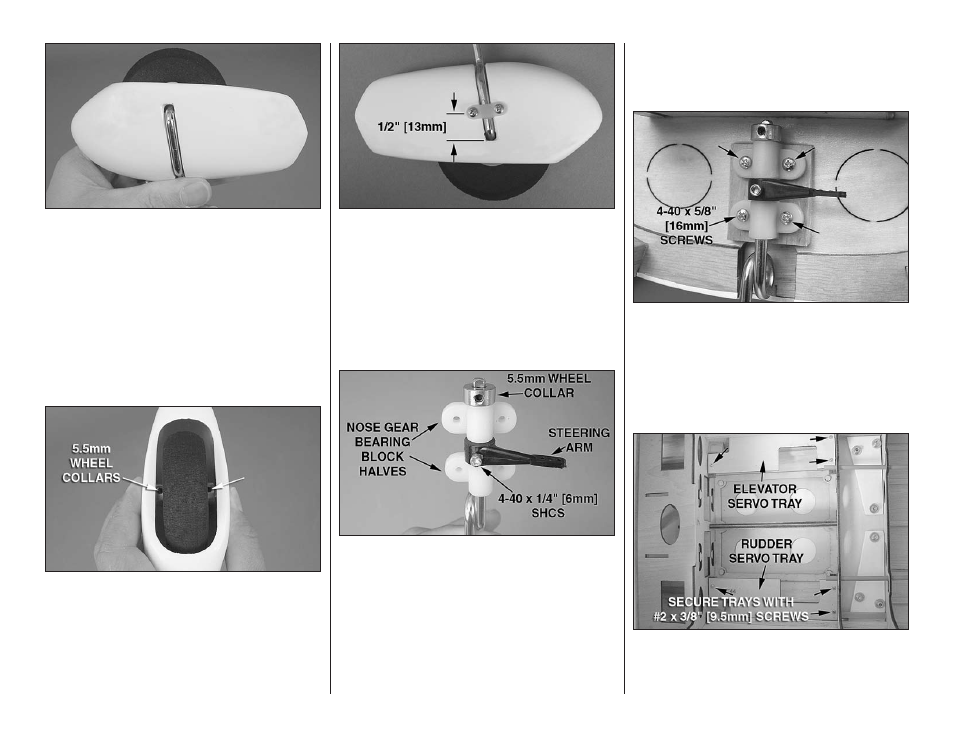

6. Insert the nose gear wire into the front wheel pant

as shown. Slide a 5.5mm wheel collar onto the nose

gear wire followed by the 2-3/4" [70mm] nose wheel,

and another 5.5mm wheel collar. Center the wheel in

the pant and mark the location of the wheel collars

onto the nose gear axle. As you did with the main

landing gear, file flat spots at the marks you made.

o

7. Loosely thread a 3 x 4mm machine screw with

threadlocking compound into each 5.5mm wheel

collar. Reinstall the wheel collars and nose wheel

onto the nose gear wire along with the wheel pant.

Tighten the screws in the wheel collars onto the flat

spots you made on the axle. Confirm that the wheel

spins freely on the axle. Add oil as necessary.

o

8. Center the nylon landing gear strap onto the

nose gear wire 1/2" [13mm] above the axle. Mark the

location for the mounting holes. Carefully drill 3/32"

[2.4mm] holes at your marks. Thread a #4 x 3/8"

[9.5mm] self-tapping screw into each hole and back

it out. Apply a drop of thin CA to each hole to harden

the wood. When the CA has hardened, attach the

strap to the wheel pant using two #4 x 3/8" [9.5mm]

self-tapping screws.

o

9. Cut the nylon nose gear bearing block into two

pieces as shown and flip them over. Sand the top

and bottoms of the pieces smooth. Loosely thread a

4-40 x 1/4" [6mm] SHCS with threadlocking compound

into the nylon steering arm. Loosely thread a 3 x 4mm

machine screw into the remaining 5.5mm wheel collar

with threadlocking compound. Slide one of the bearing

blocks onto the nose gear wire followed by the steering

arm, the other bearing block, and then the wheel collar.

Tighten the SHCS in the steering arm against the lower

flat spot on the nose gear wire and tighten the set screw

in the wheel collar against the upper flat spot. Be careful

when tightening the SHCS in the steering arm to prevent

stripping the brass insert in the arm.

o

10. Mount the nose gear bearing block pieces to

the firewall using four 4-40 x 5/8" [16mm] machine

screws and threadlocking compound. If necessary, oil

the nose gear wire to ensure that it rotates smoothly

within the bearing block.

INSTALL THE TAIL SERVOS & PUSHRODS

o

1. Position the

elevator and rudder servo trays onto

the hardwood rails glued inside the fuselage as shown.

Drill through the mounting holes in the trays into the

16