Top Flite TOPA0310 User Manual

Page 43

❏ ❏

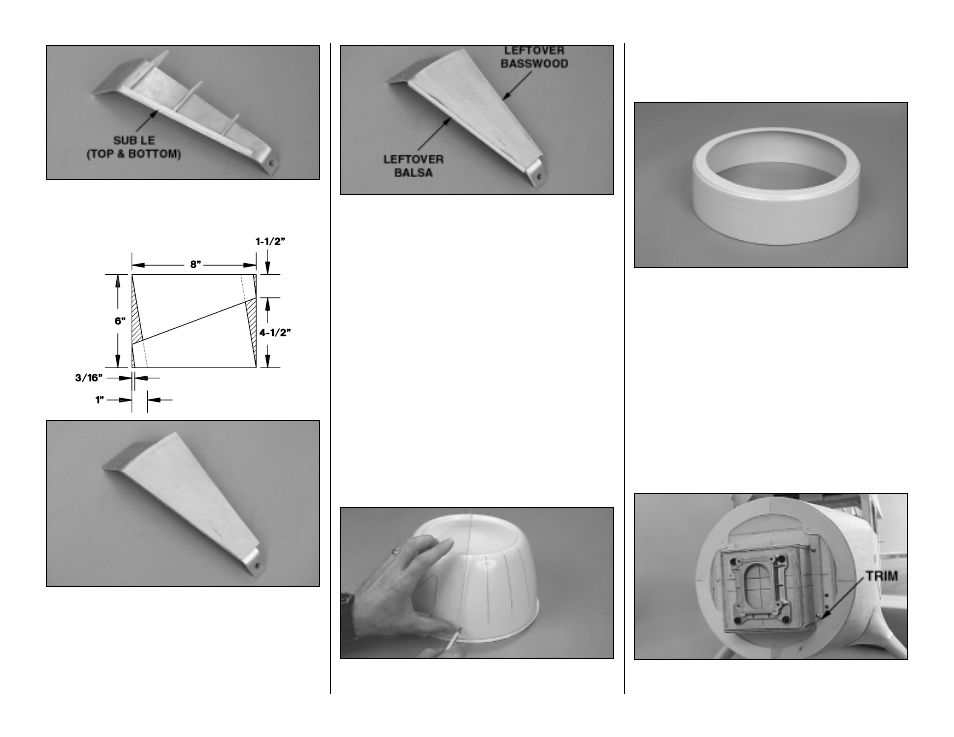

4. Shape the sub LE’s to match the downward

curving angle of the ribs.

❏ ❏

5. Cut two

landing gear skins

from the 1/32"

x 6" x 8" plywood sheet using the dimensions shown

in the sketch. Glue one of the skins to the top of the

landing gear and the other to the bottom.

❏ ❏

6. Sand the sheeting even with the front of the

aluminum gear and the end of the ribs.

❏ ❏

7.

Glue leftover 1/8" balsa to the LE and

leftover 1/8" x 1/4" basswood to the TE of the gear.

Blend the LE and TE to the sheeting. The landing

gear may now be covered with iron-on covering, but

for the best durability and appearance, it is

recommended that the landing gear be covered with

glass cloth and resin, then primed and painted.

❏

8. Build the other landing gear the same way. Be

certain to make a right and a left, as both aluminum

landing gears are the same.

Mount the Cowl

❏

1. Trim the bottom flange around the molded ABS

forward cowl

so that approximately only 1/8” remains.

Use 250-grit sandpaper to thoroughly scuff the outside

of the cowl so you can make marks with a pencil. Place

the forward cowl and a pencil on a flat surface. Hold the

pencil to the base of the cowl and turn the cowl around

the pencil marking a trim line all the way around.

❏

2. Use a builder’s square as a guide to mark lines

extending from the molded-in “dots” near the bottom

of the cowl to the front of the cowl. These will be used

later for aligning the cowl blisters. Trim the forward

cowl along the line you marked around the base.

❏

3. Mark and trim the bottom of the molded ABS

aft cowl

the same way. Cut a hole in the middle of

the aft cowl leaving a 1/2" ring all the way around.

Save the leftover circular sheet of plastic for the

pushrod exit covers to be made later.

❏

4.

Thoroughly

sand the inside of the forward and

aft cowl, and the groove where the forward cowl will

join the aft cowl with coarse sandpaper so glue and

glass cloth will adhere.

❏

5. Center the forward cowl on the aft cowl and

glue them together with CA. Refrain from using CA

accelerator because it may soften the plastic.

❏

6. Determine where to fit the four die-cut 1/8"

plywood

aft cowl ring sections

on the firewall. The

- 43 -