Tie Down G5 User Manual

Page 5

4

Bolt & Nyloc Nut

Bolt &

Nyloc Nut

Brake

Flange

Rotor/Hub

Caliper

Brake

Flange

Caliper

Mounting

Bracket

Mounting

Bracket

Slider Pin

Brake Line

Bolt & Nyloc Nut

Bolt &

Nyloc Nut

Brake

Flange

Rotor/Hub

Caliper

Brake

Flange

Caliper

Mounting

Bracket

Mounting

Bracket

Slider Pin

Brake Line

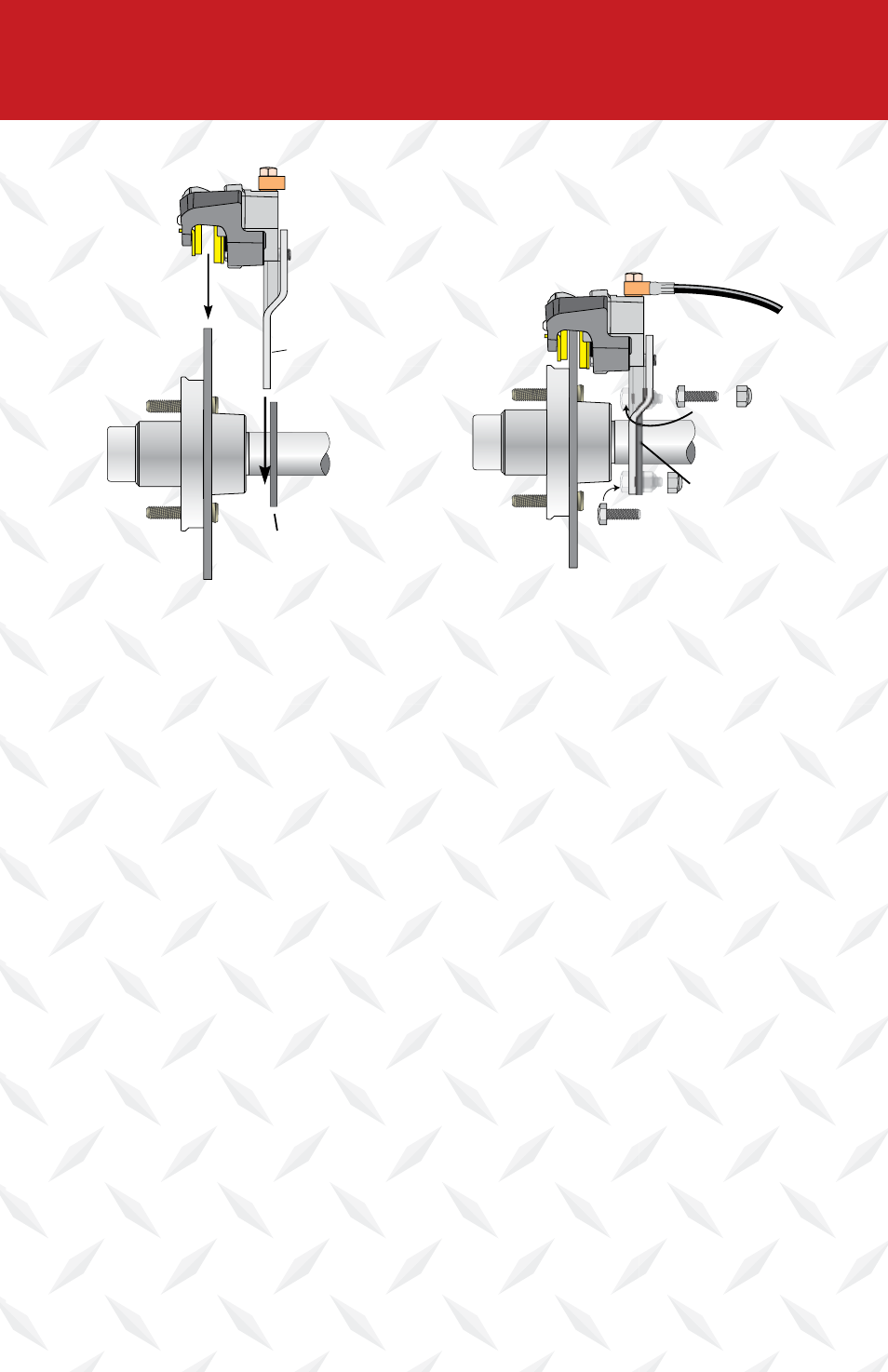

Slide caliper/mounting bracket

over rotor

Bolt mounting bracket to the

brake flange

10. Slide the assembled caliper onto the slider pins. Attach the assembled mounting

plate to the brake flanges on the axle, after sliding the caliper over the stainless

steel rotor. Preferred positions are 12:00, 9:00 and 3:00 “o-clock” or to the

backside. The brake flange will determine the exact positioning. Use 7/16”x 1-1/4”

zinc hex bolts, lock nuts/washers and torque to 40 ft. lbs.

11. Replace grease cap.

12. Caliper has a swivel inlet connector for the brake hose and a stainless steel bleeder

valve. The bleeder valve should have the top or highest position on the caliper.

Position the swivel brake connector so that the brake line easily connects to the

caliper. Tighten the bolt on the swivel connector to 20 ft. lbs.

13. Connect the flexible brake line to the swivel connector.

14. Repeat this assembly for the other wheels.

15. Install tire/wheel assembly(s), tighten wheel nuts to Trailer manufacturer or wheel

manufacture’s specifications. Test wheel for excessive tightness or excessive play.

Re-tension spindle nut if necessary.

16. Bleed brakes according to the trailer actuator’s instructions.

17. Road test vehicle in a safe place before traveling on main roads in traffic.

VERY IMPORTANT,

RE-CHECK LUG NUTS FOR PROPER TORQUE AFTER 25 MILES OF USE.