Tie Down 80 Weld-On Actuators User Manual

Welding instructions, Model 66 & model 80 weld-on actuators

TIE DOWN ENGINEERING • 255 Villanova Drive SW • Atlanta, GA 30336

www.tiedown.com (404) 344-0000 Fax (404) 349-0401

MMDD

YY

,AXXX

Welding Instructions

Model 66 & Model 80

Weld-On Actuators

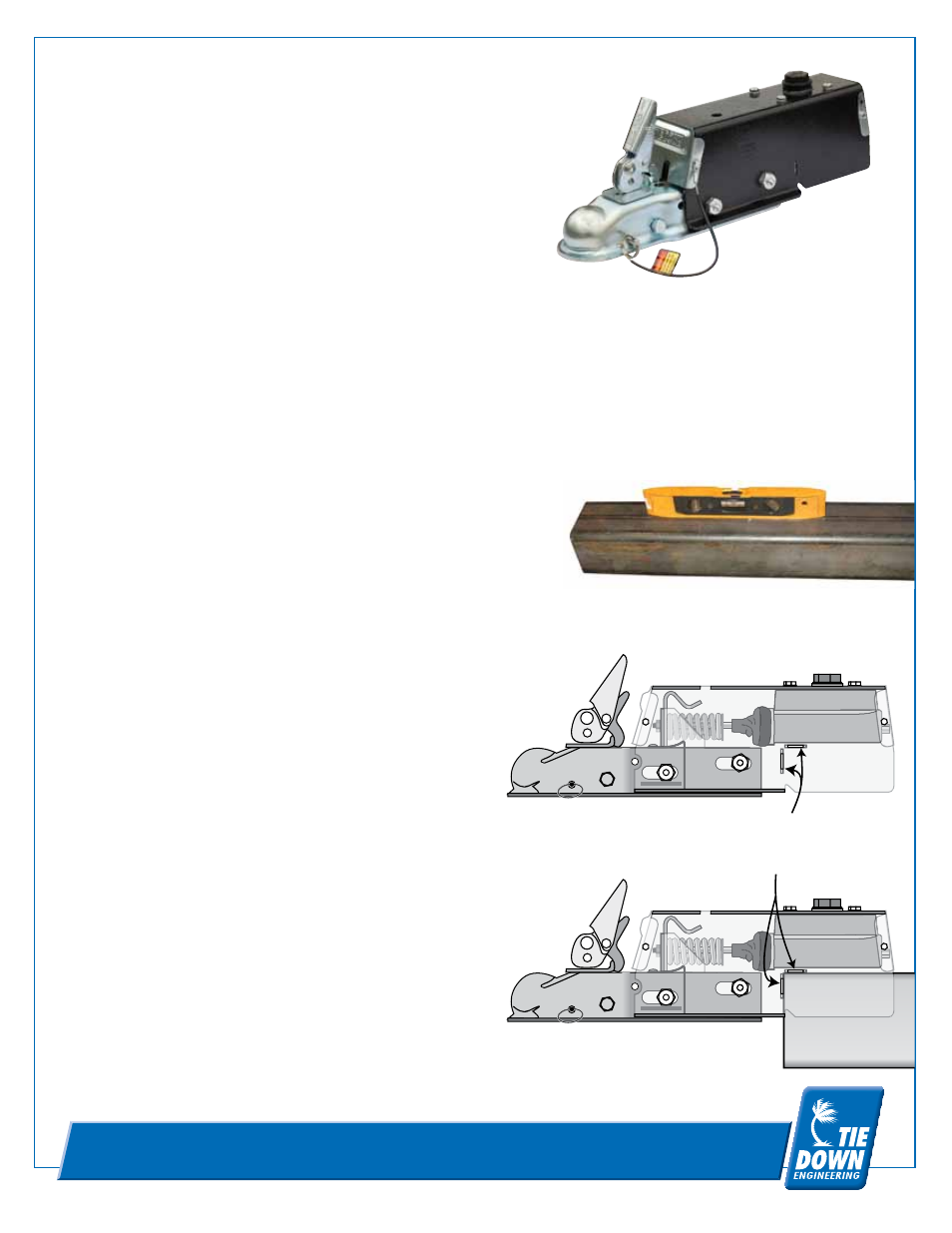

Actuator is shipped with the rear cover attached to the

actuator housing. Leave the rear cover on for positioning

and the first “Tack” welds to hold the actuator in position.

The rear cover will be removed during the remainder of the

welding operation.

1. Trailer tongue should be level with the trailer secured

so that it will not roll or move during welding. (picture #1)

Remove coupler or original actuator from the

trailer tongue.

Thouroughly clean surface of the tongue where the

new actuator will be welded to the tongue.

2. Place new Tie Down Engineering actuator on tongue

as shown on right. Actuator must be placed on the

trailer tongue so that the end of the tongue is

touching the angle plate on the underside of the

actuator as shown right (picture #2. Tongue and

actuator must be level (pictures 1 & 2).

WARNING- must be knowledgeable in welding. If you are not comfortable with welding the actuator

to your trailer tongue, have a professional do this for you. Warranty does not cover damage caused

by faulty welding.

Washer

Two angle plates set at 90˚ on the

underside of the master cylinder

“Tack” weld

(one on each side)

“Full” weld

(on both sides)

Trailer

Tongue

Picture #1

Picture #2

Instruction Sheet #08112

052808,A1025