Tie Down G5 User Manual

Page 4

3

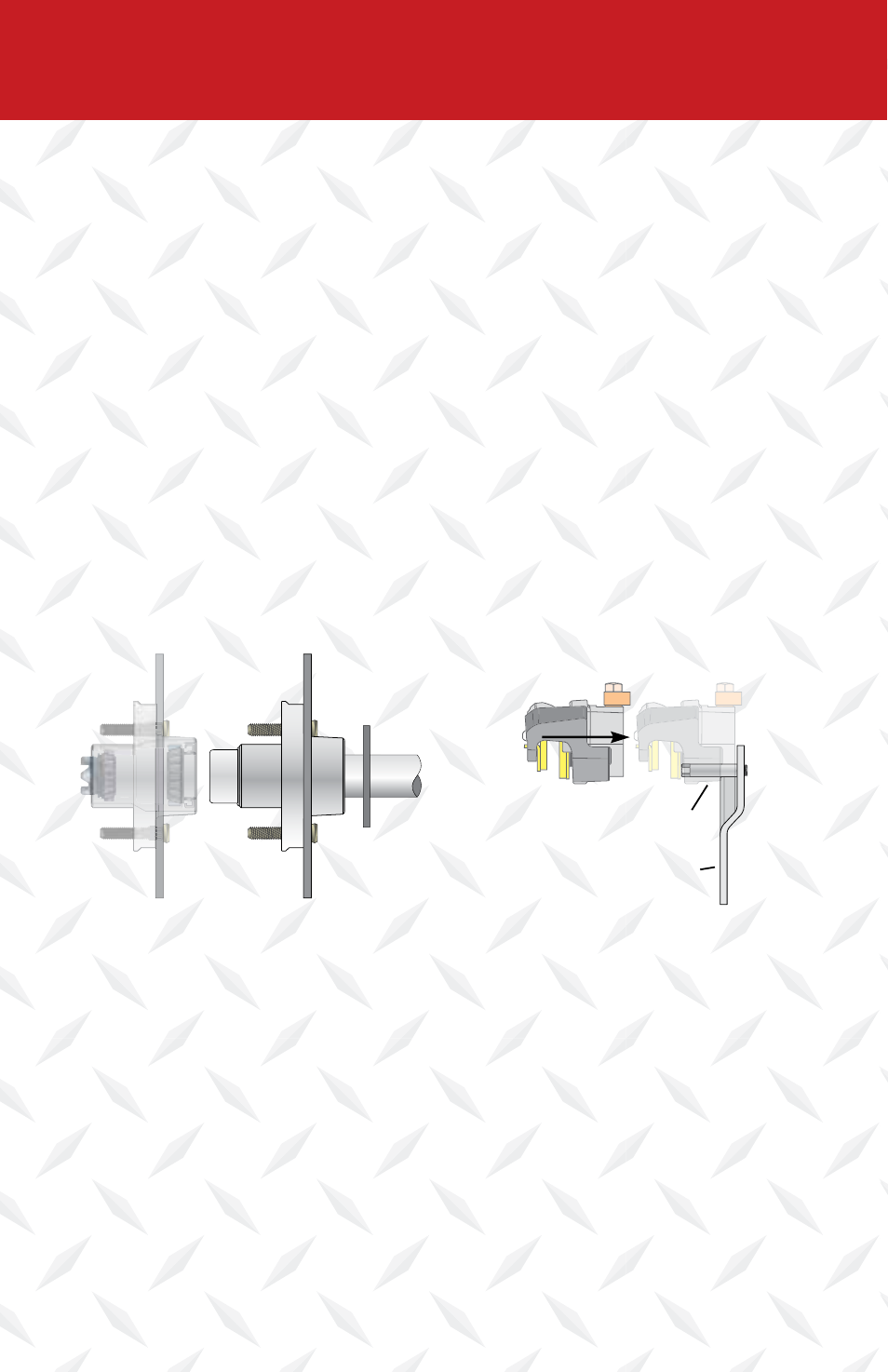

Bolt & Nyloc Nut

Bolt &

Nyloc Nut

Brake

Flange

Rotor/Hub

Caliper

Brake

Flange

Caliper

Mounting

Bracket

Mounting

Bracket

Slider Pin

Brake Line

Bolt & Nyloc Nut

Bolt &

Nyloc Nut

Brake

Flange

Rotor/Hub

Caliper

Brake

Flange

Caliper

Mounting

Bracket

Mounting

Bracket

Slider Pin

Brake Line

Install rotor/hub on spindle

Slide caliper onto the slider pins

6. Loosen the spindle nut to remove the torque, do not rotate hub.

7. Tighten the spindle nut until snug, backing out only to line up the locking tang

washer or cotter pin to the first available position.

8. Bend the locking tang tab or cotter pin in place.

9. Your G5 brakes come with pre-assembled mounting brackets and stainless steel

slider pins. DO NOT REMOVE SLIDER PINS. If the slider pins are removed for any

reason the threads must be cleaned and a new coat of “permanent” Loctite®

must be applied. Clean and apply Loctite® to threads on the mounting plate. Be

careful not to get Loctite® on slider pins or bushings. Torque slider pins

to 40 ft. lbs

1. Elevate the trailer on a level surface using the trailer manufacturer’s instructions.

Always use jack stands for support. Do not depend on a jack to support the trailer.

Block wheels to keep trailer from rolling.

2. If installation is on a completed trailer, remove tire/wheel.

3. Disc Brakes require the use of flexible brake lines attached to the caliper. The

calipers “float” and should not be used with metal brake lines that will restrict

movement and cause overheating or brake failure. If you are replacing existing

brakes and have metal brake lines, either replace the metal brake lines with a Tie

Down Engineering flexible brake line kit or add flexible extensions to the metal lines

to connect to the disc brake calipers.

4. Remove existing brakes or hubs. Clean spindles with a soft cloth to remove old

grease and containments. Coat the spindle with a light coat of clean oil or grease to

allow a smooth installation of the hub/rotor.

5. Place the G5 hub/rotor on the spindle. Install the washer and castle nut supplied

with your axle, Rotate the hub while tightening the spindle nut to approximately

50 ft lbs. This translates into full hand pressure with a 12” long set of pliers or

12” long wrench.

“G5” Installation/Replacement Instructions for

9.6” 5-Lug Stainless Steel Disc Brakes