Chapter 2 - installation, Mounting bracket, Pressure gauge – TeeJet 744E SPRAYER CONTROL User Manual

Page 12: Mounting bracket pressure gauge, 744e sprayer control

8

www.teejet.com

744E Sprayer Control

CHAPTER 2 - INSTALLATION

Mounting Bracket

1. Make sure all switches on the 744E Sprayer

Control are turned to the “Off” position.

2. Determine the best location for the 744E Sprayer

Control in the vehicle cab according to the following

guidelines:

• pressure gauge should be readily visible

• switches should be within easy reach

• controller bracket should rest on a flat surface

• 12 volt DC power source must be accessible

(maximum draw 10 amps)

3. Determine the proper routing for power cables and

pressure tube:

• away from operators’ movement area

• away from moving parts

• away from sharp objects

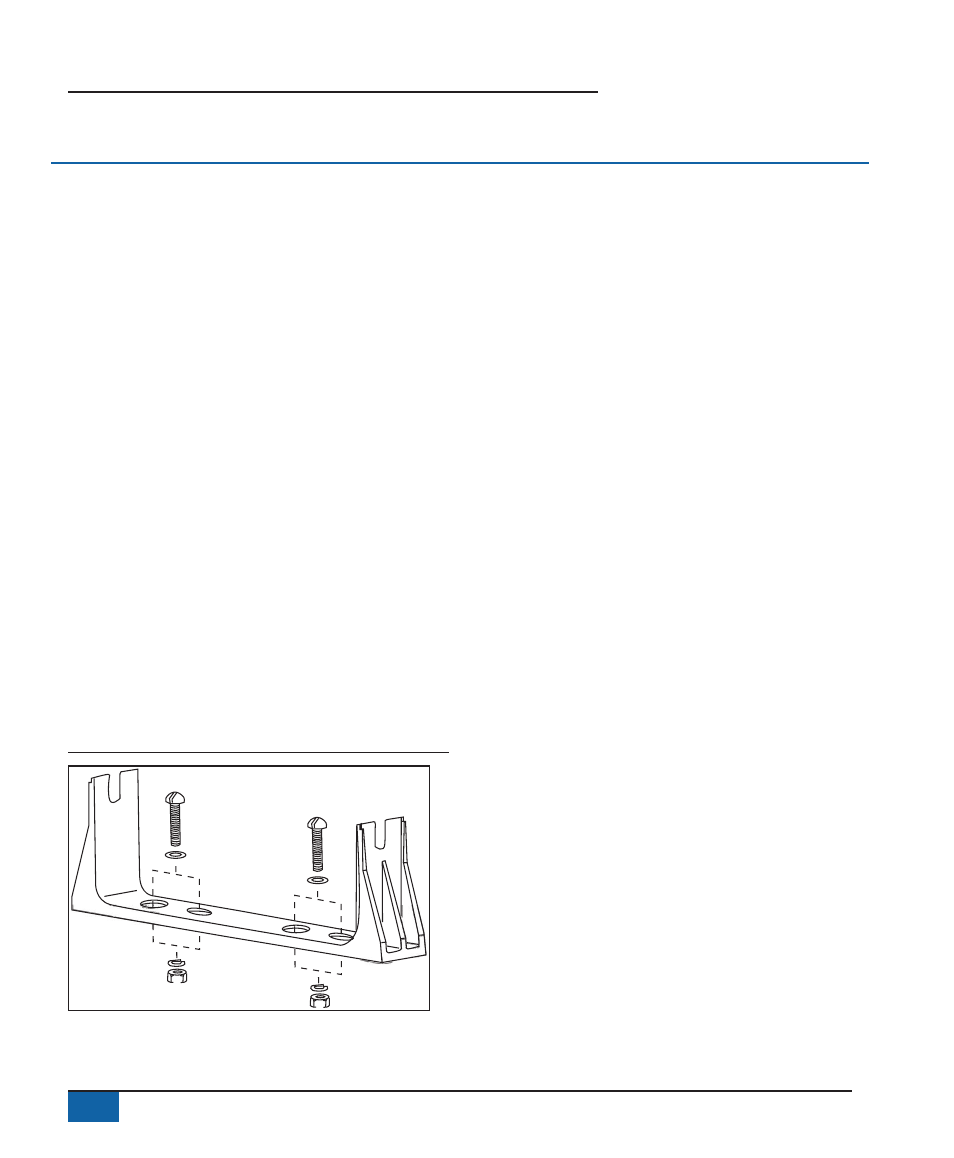

4. Install the mounting bracket using ¼″ (6.4 mm) drill,

machine screws, nut, washers and lock washers

as illustrated below. Attach the control housing

assembly to the mounting bracket using the

console adjusting knobs and washers.

Figure 2-1: Mounting bracket

Pressure Gauge

The tubing for the pressure gauge is supplied as part of

the wiring harness. To avoid chemical leakage into the

vehicle cab, the tube coupler must be installed outside

of the vehicle cab. If a gauge isolator is used with the

system, it should be installed in place of the coupler,

also outside of the vehicle cab.

The pressure gauge should be checked for accuracy

each season. If the unit is equipped with a liquid-filled

gauge and it does not read accurately, the gauge may

need to be vented. To vent the gauge, remove the four

screws in the back of the sprayer control housing and

lift off the back. The rear of the gauge will be exposed.

To vent the gauge, clip off the nib of the rubber plug

in the back of the gauge or puncture it with a needle.

Once the gauge has been vented, do not store the

sprayer control on its back as this may cause a loss

of fluid from within the gauge. If further inaccuracy

is suspected at 0 PSI (0 bar) and a gauge isolator

is being used, the isolator line may need to be bled

according to the instructions furnished with the gauge

isolator.