9 - checking and adjusting co2 levels, 12 - start-up, Warning – Slant/Fin VSL-160C Part B User Manual

Page 31

67

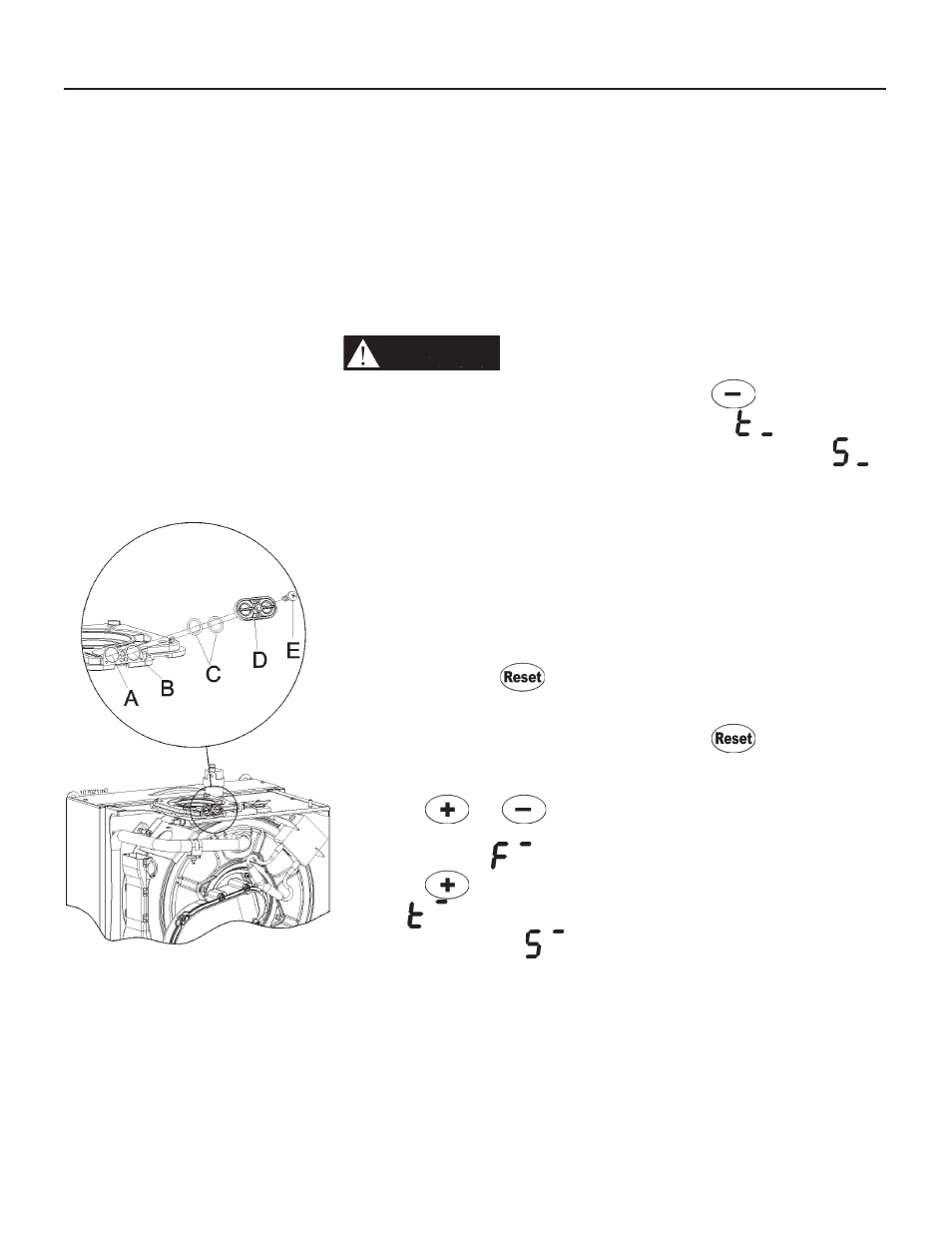

A = air probe

B = fl ue exhaust probe

C = O-ring gaskets

D = cap

E = fi xing screw

Figure 12-6

Combustion

analysis probes

12.9 - Checking and

adjusting CO2 levels

Table 11-3 lists the correct CO2 ranges

for a boiler running at normal operating

conditions at an altitude below 2000

ft (600m). CO2 values outside of the

ranges given in Table 11-3 may lead to

malfunctioning of the boiler and cause

it to prematurely fail. To check the CO2

value, carry out a combustion analysis

as follows while referencing Figure 12-6:

WARNING!!!

During this

procedure compare also CO

(carbon monoxide) reading, with

the value given in Table 11-3. If

this is higher, STOP the boiler

and call the Factory service

department (see phone number

on the last cover page). Failure

to comply with this requirement

could result in severe personal

injury, death or substantial

property damage.

NOTE: During the 10 minutes

override mode, if the demand on

the boiler is low causing the fl ue

gas temperature to increase rapidly,

boiler will go into lock out code L06.

To reactivate it, press

button.

1. carefully remove items “E”, “D” and

“C” from the combustion air/ vent

fi tting:

2. generate a call for heat; and wait up

the boiler is light-on;

4. press the

and

keys for

more than 10 seconds, the display

will show a blinking

;

5. press the

key until the display

shows

if a call for heat has

been generated or until

is

displayed if a domestic hot water

demand has been generated. The

boiler will now run for 10 minutes at

high fi re input;

6. wait 2 to 3 minutes for the CO2 to

stabilize;

7. insert the probe of a calibrated

combustion analyzer into port “B” and

take a fl ue gas sample;

8. compare the CO2 reading with the

high fi re range given in Table 11-3,

making sure to use the range for the

gas type in use. If the CO2 reading

is outside the specifi ed range, it

must be adjusted operating on the

“E” screw of Figure 12-3. Use a

2.5mm Allen Wrench to turn the

screw (clockwise to reduce the CO2

level, counter-clockwise to increase

the CO2 level) in small increments

and wait for the CO2 to stabilize to

prevent overshooting the desired

value;

9. When CO2 level match the value of

Table 11-3, seal screw “E” with red

paint or nail polish to discourage

tampering.

10. press the

key until the

display shows

if a call for heat

has been generated or until

is displayed if a domestic hot water

demand has been generated. The

boiler will now run for 10 minutes at

low fi re input;

11. wait 2 to 3 minutes for the CO2 to

stabilize;

12. compare the CO2 reading with the

low fi re range given in Table 11-3,

making sure to use the range for the

gas type in use. The CO2 reading

must be inside the specifi ed range;

If not, STOP the boiler and call the

Factory service department (see

phone number on the last cover

page).

13. press the

button to return the

boiler to its normal operating mode.

14. close fl ue and air probe “A” and “B”

of Figure 12-6.

15. turn knob “7” and “11” of Figure

13-1 to the OFF position.

12 - START-UP