Slant/Fin Gas Steam User Manual

Page 7

7

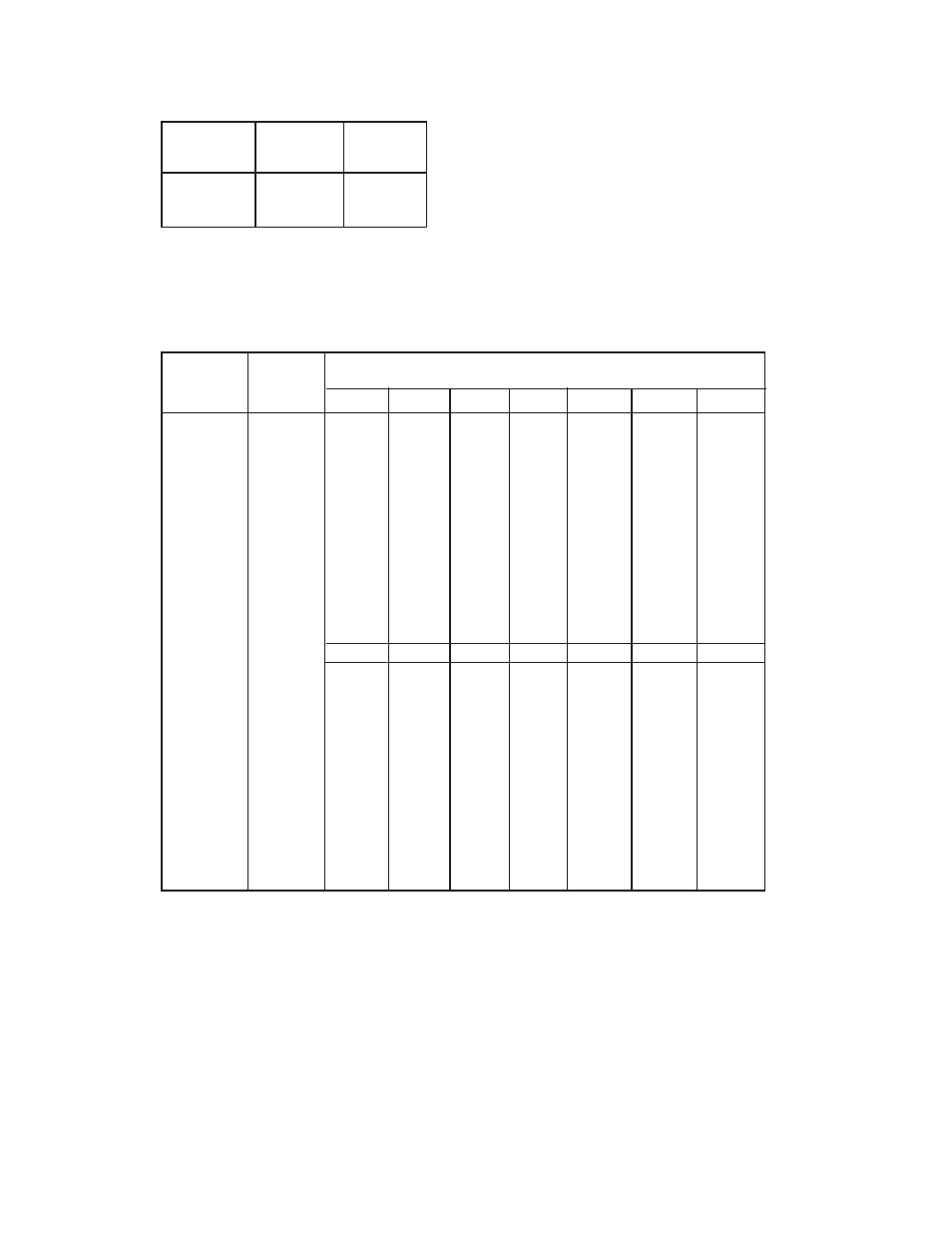

Table 6: Characteristics of various fuel gases

Natural

1000 Btu

1.00

Propane

2500 Btu

1.10

Type

of Gas

Heating

Valve †

Flow

Correction

Factor

1

⁄

4

.364

32

22

18

15

14

12

11

3

⁄

8

.493

72

49

40

34

30

27

25

1

⁄

2

.622

132

92

73

63

56

50

46

3

⁄

4

.824

278

190

152

130

115

105

96

1

1.049

520

350

285

245

215

195

180

1

1

⁄

4

1.380

1050

730

590

500

440

400

370

1

1

⁄

2

1.610

1600

1100

890

760

670

610

560

2

2.067

3050

2100

1650

1450

1270

1150

1050

2

1

⁄

2

2.469

4800

3300

2700

2300

2000

1850

1700

3

3.068

8500

5900

4700

4100

3600

3250

3000

4

4.026

17,500

12,000

9700

8300

7400

6800

6200

1

⁄

4

.364

11

10

9

8

8

7

6

3

⁄

8

.493

23

22

21

18

17

15

14

1

⁄

2

.622

43

40

38

34

31

28

26

3

⁄

4

.824

90

84

79

72

64

59

55

1

1.049

170

160

150

130

120

110

100

1

1

⁄

4

1.380

350

320

305

275

250

225

210

1

1

⁄

2

1.610

530

490

460

410

380

350

320

2

2.067

990

930

870

780

710

650

610

2

1

⁄

2

2.469

1600

1500

1400

1250

1130

1050

980

3

3.068

2800

2600

2500

2200

2000

1850

1700

4

4.026

5800

5400

5100

4500

4100

3800

3500

Nominal

Iron Pipe

Size Inches

Internal

Diameter

Inches

Table 7: Gas main sizing guide

10

20

30

40

50

60

70

80

90

100

125

150

175

200

Equivalent

Length of Pipe, Feet

Maximum capacity of pipe in cubic feet of gas per hour for gas pressures of 0.5 psig or less and a pressure drop of 0.3 inch

water column (based on a 0.60 specific gravity gas).

* per cubic foot

† Consult fuel supplier for actual BTU value.