Slant/Fin Gas Steam User Manual

Page 3

3

BOILER PLANT SIZING

Older buildings may have a heat loss significantly less than that

of the original building. To size a replacement steam boiler plant,

consider the following: Replacement steam boiler plants must be

sized to match the connected radiation load. Under-sizing will

prevent steam from reaching distant radiation quickly.

BOILER ROOM DESIGN

Caravan modular boiler systems allow better utilization of floor

space and permit future expansion with minimum cost. The mod-

ules are hand truckable, fit through doorways and often may be

installed around an existing inoperative boiler. They can be

grouped in single or multiple banks. Systems consisting of five or

more modules should be piped in two or more banks.

BOILER ROOM AIR SUPPLY

To ensure safe, efficient operation, the modular boiler system

must be supplied with sufficient air to support complete combus-

tion, replacing air entering draft dampers or draft hoods and ven-

tilating the boiler room or areas.

For additional information, not listed below, see ANSI. Z223.1,

section 5.3.3.

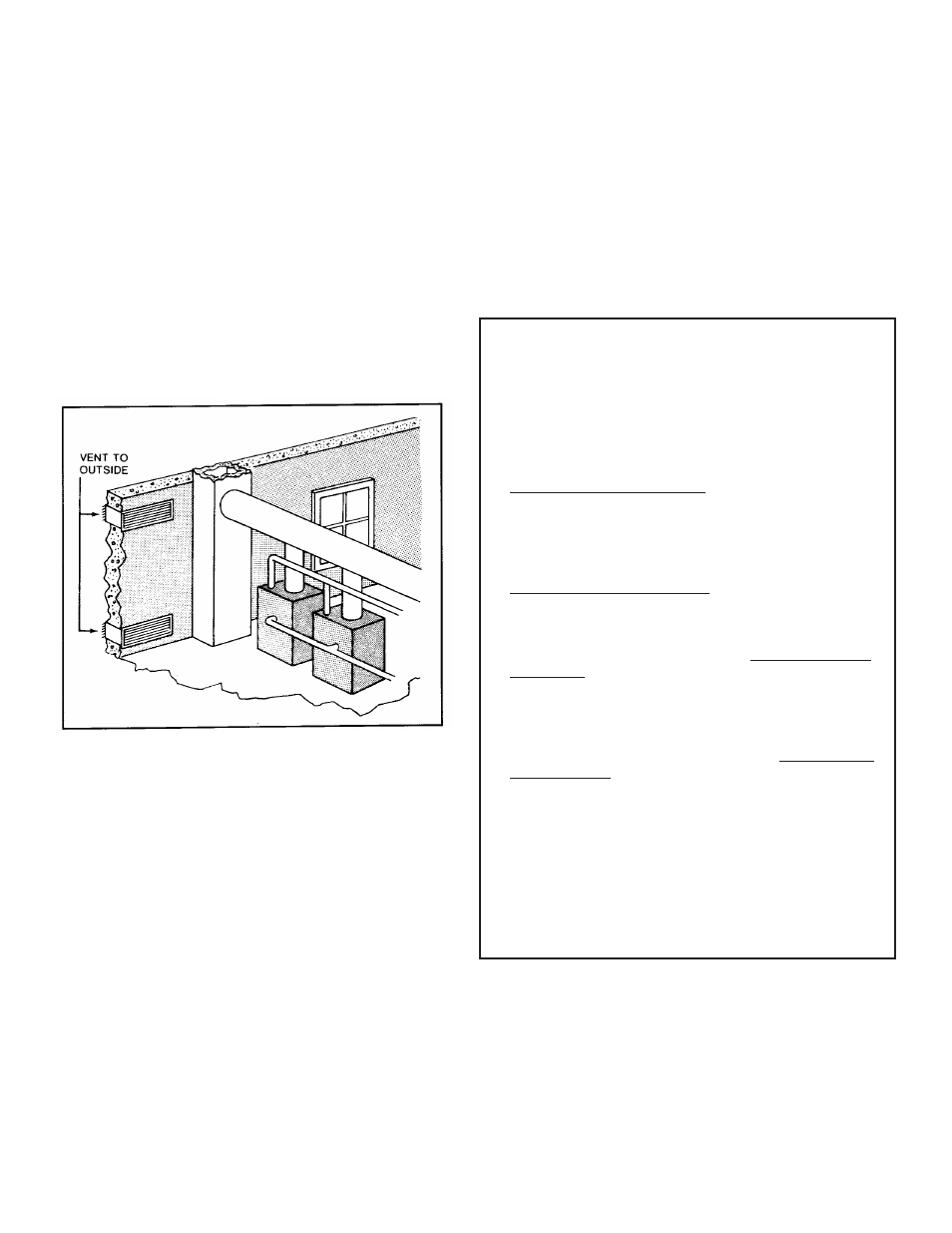

Figure 2: Correct location of combustion-air supply ducts.

INSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

TWO UNOBSTRUCTED OPENINGS FOR PASSAGE OF AIR

INTO THE BOILER ROOM:

1. Air drawn horizontally from outdoors DIRECTLY

through an outside wall; one louvered opening near the

floor (below burner air inlet) and one louvered opening

near the ceiling (above the highest draft regulator), each

opening with a minimum FREE air passage area of

1 square inch per 4000 BTUH of total system input.

2. Air drawn horizontally through HORIZONTAL DUCTS;

one opening near the floor (below burner inlet) and one

opening near the ceiling (above the highest draft regulator),

each opening with a minimum FREE air passage area of

1 square inch per 2000 BTUH.

3. Air drawn VERTICALLY from outdoors; one opening at

the floor and one opening at the ceiling, each opening with

a minimum FREE air passage area of 1 square inch per

4000 BTUH of total system input.

4. Air drawn from inside the building; one opening near

the floor (below burner inlet) and one opening near the

ceiling (above the highest draft regulator), each opening

with a minimum FREE air passage area of 1 square inch

per 1000 BTUH of total system input.

IF BOILERS ARE INSTALLED ADJACENT TO OTHER FUEL

BURNING EQUIPMENT, THE AREA OF FREE OPENINGS

MUST BE APPROPRIATELY INCREASSED TO ACCOMMO-

DATE THE ADDITIONAL LOAD.

UNLESS PROPERLY CONTROLLED, AVOID THE USE OF

FORCED VENTILATION, SINCE IT CAN CREATE AN

UNDESIRABLE PRESSURE DIFFERENTIAL BETWEEN

BOILER ROOM AND AIR SOURCE.