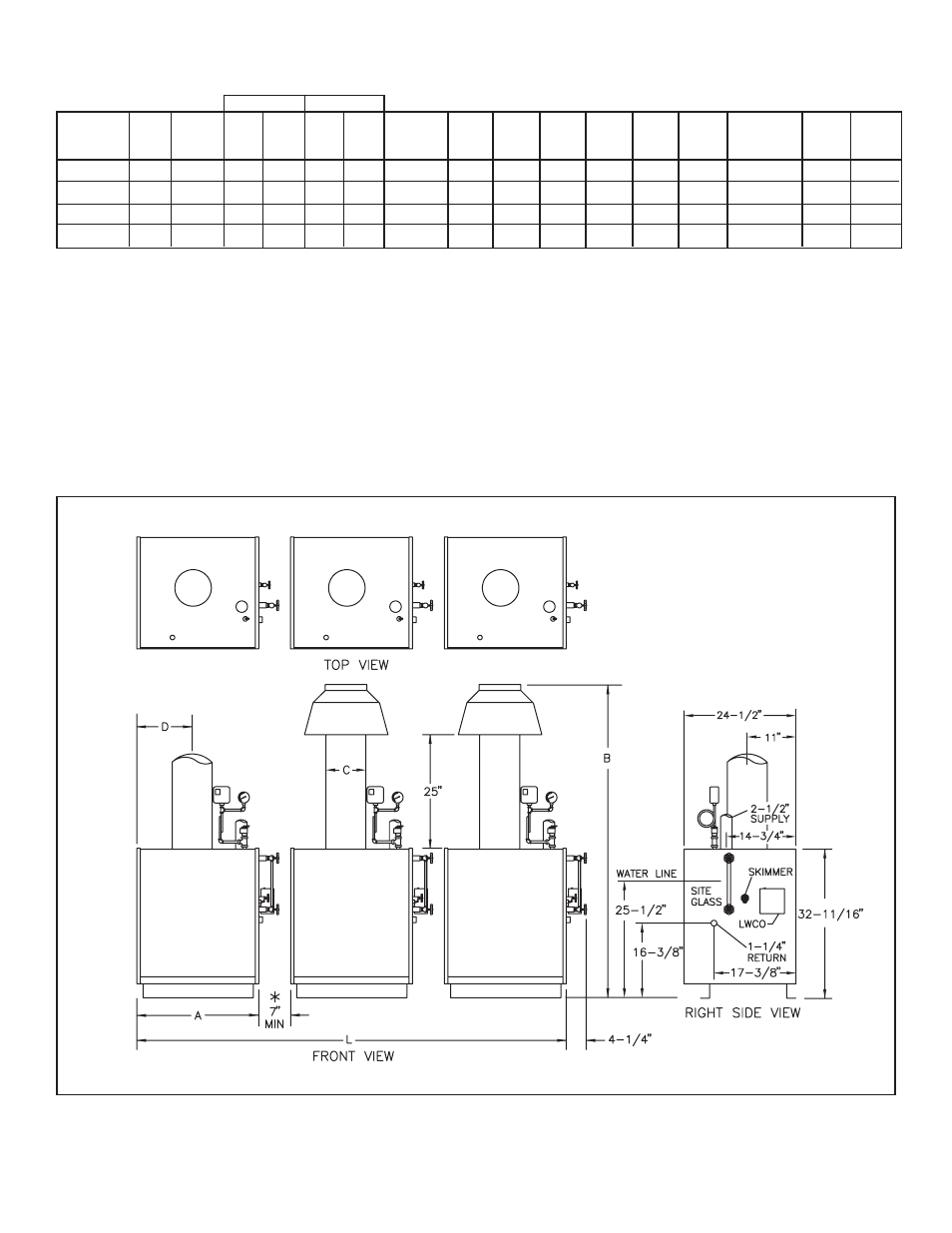

Table 1: ratings and dimensions – Slant/Fin Gas Steam User Manual

Page 2

2

GXHT-600 Z

2

GXH-300

600

478

358

1492

14.78

16.8

1075

26

1

⁄

16

”

59

1

⁄

8

”

9”

7”

3”

11

17

⁄

32

”

4’ 11

1

⁄

8

”

GXHT-900 Z

3

GXH-300

900

717

537

2238

21.42

25.2

1595

26

1

⁄

16

”

59

1

⁄

8

”

9”

7”

4”

11

17

⁄

32

”

7’ 8

3

⁄

16

”

GXHT-1200 Z

4

GXH-300

1200

956

716

2983

28.56

33.6

2115

26

1

⁄

16

”

59

1

⁄

8

”

9”

7”

5”

11

17

⁄

32

”

10’ 5

1

⁄

4

”

GXHT-1500 Z

5

GXH-300

1500

1195

895

3729

35.70

42

2635

26

1

⁄

16

”

59

1

⁄

8

”

9”

7”

6”

11

17

⁄

32

”

13’ 2

5

⁄

16

”

Model No.

Number

of

Modules

Module

Model

Number

Input

M.B.H

Gross

Output

M.B.H

Net

Output

M.B.H

Net

Sq. Ft.

Steam

Horsepower

Boiler

Water

Content

(Gals)

Shipping

Weight

Lbs.

“A”

Dim

Minimum

Space

Between

Modules

Recommended

Header

Size

“B”

Dim

“C”

Dim

“D”

Dim

“L”

Dim

CSA

AHRI

Table 1: Ratings and dimensions

For larger sizes, use multiple of the above

Specify gas by name, “natural” or “propane”.

Net ratings are based on piping and pick-up

allowance of 1.33. Slant/Fin should be con-

sulted before selecting a boiler for installation

having unusual piping and/or pick-up require-

ments.

Ratings must be reduced by 4% at 2000 ft.

elevation and an additional 4% for every

additional 1000 ft. elevation over 2000 ft.

Modules in excess of 5, should be piped

in banks of 5, parallel with each other.

Figure 1: For McDonnel & Miller PS 801-24 L.W.C.O Min. clearance 9"