Slant/Fin Gas Steam User Manual

Page 6

6

GAS PIPING

This section contains sizing and construction recommendations

for fuel supply piping to Caravan gas-fired modular boiler sys-

tems. Gas-fired equipment must conform not only to codes of the

local regulatory agencies, but also to additional specifications

that may be imposed by the utility or gas supplier. Therefore, the

following information should be considered only as a guideline.

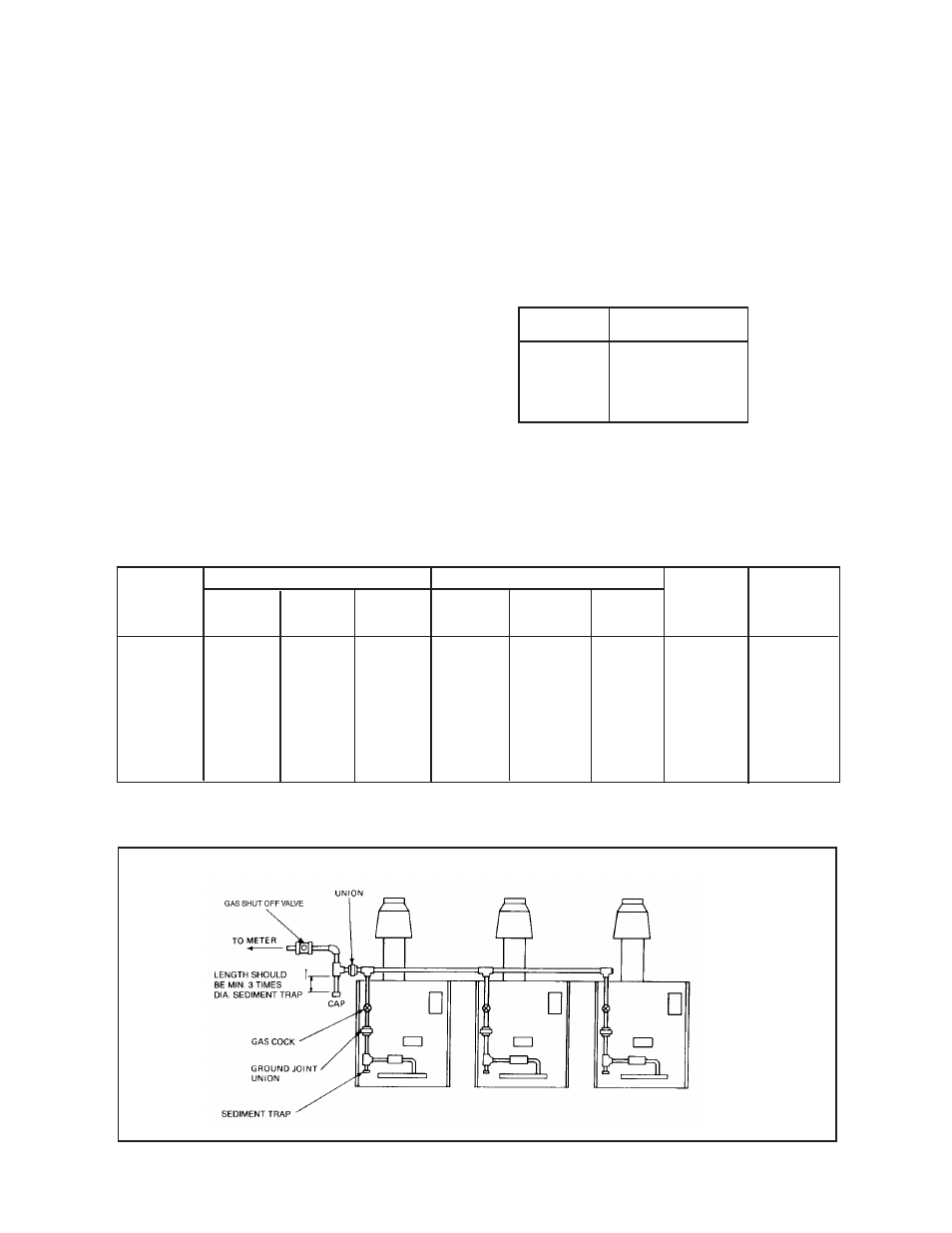

Figure 5 illustrates a typical gas supply line installation. It con-

sists of a main between the utility’s meter box and the boiler sys-

tem, a main shut-off valve, sediment trap, gas header pipe and

drip legs on individual boilers.

Individual gas lines to individual boiler modules should be

3

⁄

4

-inch

diameter. Size of gas main header pipes depends on volume of

gas required and acceptable pressure drop between meter and

modules’ gas regulator valves. Minimum pressure required at

each valve is 5-inches of water column for natural gas and 11-

inches for propane gas, measured while all boilers and other gas-

fired equipment on the same meter are firing. Small variations in

gas flow can be compensated for by adjusting gas regulator

valves. However, final pressure of gas header must vary no more

than + 0.3-inches of water column.

GAS MAIN SIZING

To determine the correct pipe diameter for the gas main serving a

specific Caravan system, proceed as follows:

a. Follow the building plans, find total length of straight pipe

between supply from gas meter and boiler gas header.

b. Using data in Table 5, calculate equivalent linear length of

screw pipe fittings used in fabrications of main. Add this to

figure from step (a) to obtain equivalent total length.

c. Find Caravan gas consumption in cubic feet per hour from

Table 4.

d. Multiply the system total hourly gas consumption by flow

correction value from Table 6, page 7.

e. Locate system’s total equivalent pipe length in right column of

Table 7.

f. Move vertically to the system’s corrected flow rate calculated in

step (c). If this value falls between two of those listed, select

larger value.

g. From this point, move horizontally to the left column and read

suggested pipe diameter for gas main.

Table 4: Gas Consumption Rate

GXHT600Z

600

GXHT900Z

900

GXHT1200Z

1200

GXHT1500Z

1500

Model No.

Gas

Consumption in CFH

1

⁄

2

0.84

0.52

0.41

0.031

2.50

1.12

1.25

1.66

3

⁄

4

1.17

0.73

0.57

0.044

3.50

1.84

1.75

2.33

1

1.57

0.98

0.77

0.057

4.68

2.11

2.34

3.11

1

1

⁄

4

2.19

1.37

1.07

0.082

6.54

2.94

3.27

4.35

1

1

⁄

2

2.63

1.64

1.29

0.098

7.84

3.52

3.92

5.21

2

3.55

2.23

1.74

1.320

10.60

4.77

5.30

7.05

3

5.72

3.59

2.81

2.130

17.08

7.69

8.84

11.40

Pipe

Size

Inches

Standard

Table 5: Equivalent linear length in feet of standard iron pipe fittings for natural gas

Medium

Sweep

Long

Sweep

Gate

Globe

Angle

Return

Bend

Side

Outlet

Tee

Elbow

Valve

Figure 5: Typical gas supply line installation