Culligan Gold Series User Manual

Page 16

Plumbing Connections

Shipped with each softener is a Culligan

®

bypass valve, which is used to connect the softener to the

plumbing system. The bypass allows the softener to be isolated from the water service line if service

is necessary while still providing water to the home. The bypass valve can be directly plumbed into

the system, or can be connected with the following optional sweat connection kits;

P/N 01010783 1” Sweat Copper Adapter Kit

P/N 01016564 3/4” Sweat Copper Adapter Kit

P/N 01016565 3/4” Elbow Sweat Copper Adapter Kit

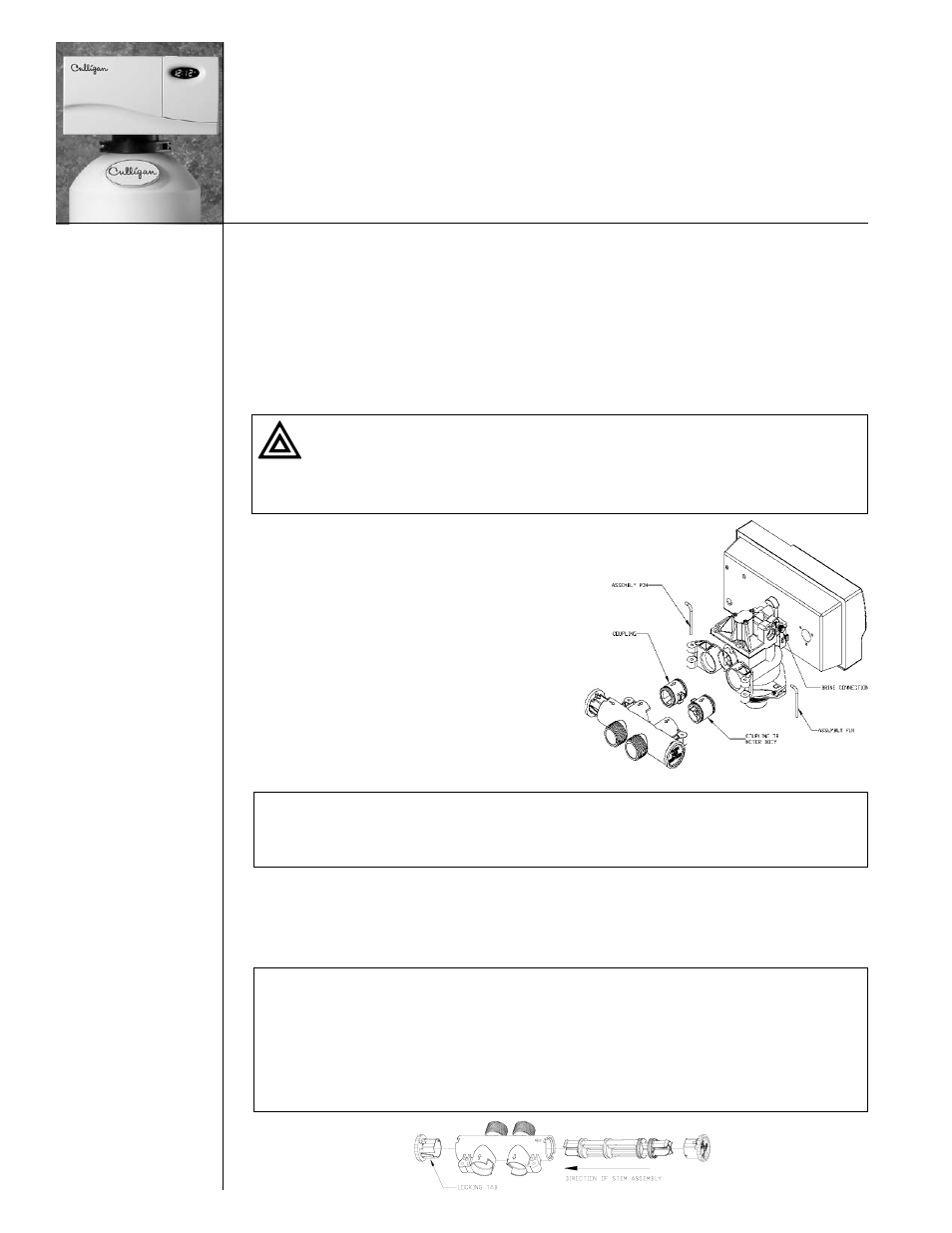

Bypass Valve Installation

The bypass valve connects directly to the

control valve with a pair of couplings and two

assembly pins (Figure 15). Lubricate all o-rings

on the couplings with silicone lubricant.

On Soft-Minder

®

meter controls, the meter

replaces the coupling on the outlet side of the

control. The meter body fits in the same space

as the coupling between the control valve and

the bypass. Make sure that the arrow on the

flow meter is pointing in the direction of flow

(Figure 7).

The bypass valve has knobs that easily snap on and off of the stem. A screwdriver can be used to

depress the snap lever on the stem for knob removal. The knobs have alignment tabs that mate into

the notches in the bypass body to ensure that the stem is properly aligned in the bypass body. The

service knob (blue) has a locking feature, which must be depressed in order to shift the stem out of

the bypass position (Figure 16).

16

Caution! Close the inlet supply line and relieve system pressure before cutting into the

plumbing! Flooding could result if not done!

Caution! When making sweat connections, use care to keep heat away from the plastic

nuts used to connect the plumbing to the bypass. Damage to these components may result

otherwise.

Note: If the ground from the electrical panel or breaker box to the water meter or underground

copper pipe is tied to the copper water lines and these lines are cut during installation of the

bypass valve, an approved grounding strap must be used between the two lines that have been

cut in order to maintain continuity. The length of the grounding strap will depend upon the number

of units being installed. In all cases where metal pipe was originally used and is later interrupted

by the bypass valve to maintain proper metallic pipe bonding, an approved ground clamp c/w

not less than #6 copper conductor must be used for continuity. Check your local electrical code for

the correct clamp and cable size.

Figure 8

Note: The bypass stem can only be removed from valve on the bypass side (red knob). The

bypass valve is designed so that it can be flipped over, with the bypass (red) knob on the left side

of the valve. This will need to be taken into consideration if the control is plumbed in close to a

wall which may prevent the stem from being easily removed.

Figure 7