Installation instructions (cont’d), Table 1 - pipe diameters and vent length, Table 2 - horizontal vent terminal clearances – Reznor UDBS Sizes 30, 45, 60, and 75 Option - Installation - Aesthetic Concentric Adapter User Manual

Page 2

Form I-UDAS/UDBS-ASC, PN209344R6, Page 2

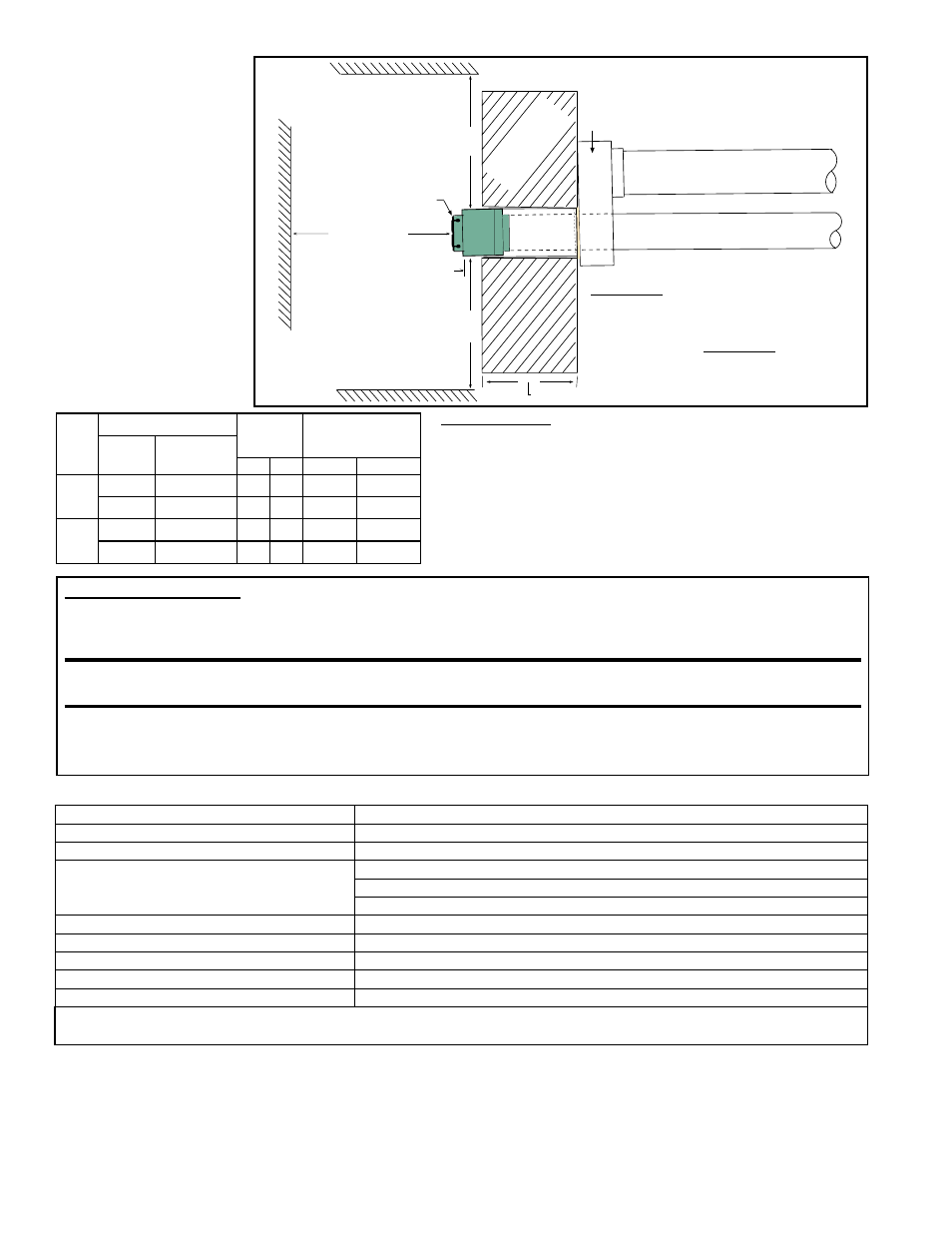

FIGURE 1 - Side

View of Horizontal

Vent using Option

CC14 Concentric

Vent/Combustion

Air Terminal

Building Overhang

Building Projection

Adjoining Building

Option CC14

Vent/Combustion

Air Terminal

4 Combustion Air

Pipe to the Heater

**3 or 4 Vent Pipe from the Heater -

See TABLE 1 for maximum length.

Painted Concentric Adapter

Box extends only 3 (76mm)

from the wall.

1(25mm) minimum; 48(1219mm) maximum

9 (229mm)

minimum

36 (914mm)

minimum

9 (229mm)

minimum

1-1/2 (38mm)

*3 vent pipe inside 4 combustion air pipe.

**4 vent pipe requires a tapered adapter to

join the vent pipe run from the heater to the

3 vent pipe extending through the concentric

adapter box. Adapter should be within 6

(152mm) of the box. 3 vent pipe run requires

a tapered adapter to connect the vent pipe

to the 4 collar on the heater.

Concentric

Pipes*

Combustible or

Non-combustible

W

all

Installation

Instructions

(cont’d)

TABLE 1 - Pipe

Diameters and Vent

Length

(All pipes

and adapters are field

supplied; see NOTES.)

TABLE 1 NOTES:

A

Category III vent pipe is required.

B

Single-wall pipe with all joints sealed or Category III pipe.

C

Requires a tapered adapter at the 4” heater outlet.

D

Requires a tapered adapter to connect the 4” vent pipe from

the heater to the 3” inner concentric vent pipe attached to the

terminal. Required length of the 3” vent pipe is the sum of the

width of the wall plus 5” (127mm).

TABLE 2 - Horizontal Vent Terminal Clearances

UDAS & UDBS

Pipe Diameter (inches) Maximum

Length

Equivalent Length

of 90° Elbow

Vent

Pipe

A

Combustion

Air Pipe

B

Ft

M

Ft

M

30 &

45

3

C

4

10

3

2

0.6

4

D

4

10

3

2

0.6

60 &

75

3

C

4

10

3

3

0.9

4

D

4

15 4.6

3

0.9

Structure

Minimum Clearances for Vent Terminal Location (all directions unless specified)

Forced air inlet within 10 ft (3.1M)*

3 ft (0.9M) above

Combustion air inlet of another appliance

6 ft (1.8M)

Door, window, or gravity air inlet (any building

opening)

4 ft (1.2M) horizontally

4 ft (1.2M) below

1 ft (305mm) above

Electric meter, gas meter ** and relief equipment

U.S. - 4 ft (1.2M) horizontally; Canada - 6 ft (1.8M)

Gas regulator **

U.S. - 3 ft (0.9M); Canada - 6 ft (1.8M) horizontally)

Adjoining building or parapet

***3 ft (.9M)

Adjacent public walkways

7 ft (2.1M) above

Grade (ground level)

3 ft (.9M) above****

*Does not apply to the inlet of a direct vent appliance. **Do not terminate the vent directly above a gas meter or service regulator. *** Clearance

based on certification testing. **** Consider local snow depth conditions. The vent must be at least 6” (152mm) higher than anticipated snow depth.

3. Assemble the field-supplied concentric pipes, the vent terminal, and the

concentric adapter box.

a) Cut to length the field-supplied, 3-inch diameter vent pipe that will be the inner

portion of the concentric pipes:

Length must be at least 5” (127mm) plus the thickness of the wall. The inner (vent)

pipe must be one piece of continuous pipe.

Vent Pipe Condensation: On units with long vent runs (over 50% of maximum vent length allowed) or installed

in low ambient conditions (below 50°F), it is recommended that the vent pipe be fitted with a tee, a drip

leg, and a cleanout cap to prevent moisture in the vent pipe from entering the unit. The drip leg should be

inspected and cleaned out periodically during the heating season.

CAUTION: Exceeding the specified vent pipe diameter and length may result in condensate

forming in the vent pipe.

The horizontal vent run

must be pitched down toward the terminal end 1/4” per foot for condensate drainage. The

slope applies to the entire length of the horizontal vent run. Failure to pitch the vent run properly may damage the

heater due to condensate running back into the unit.