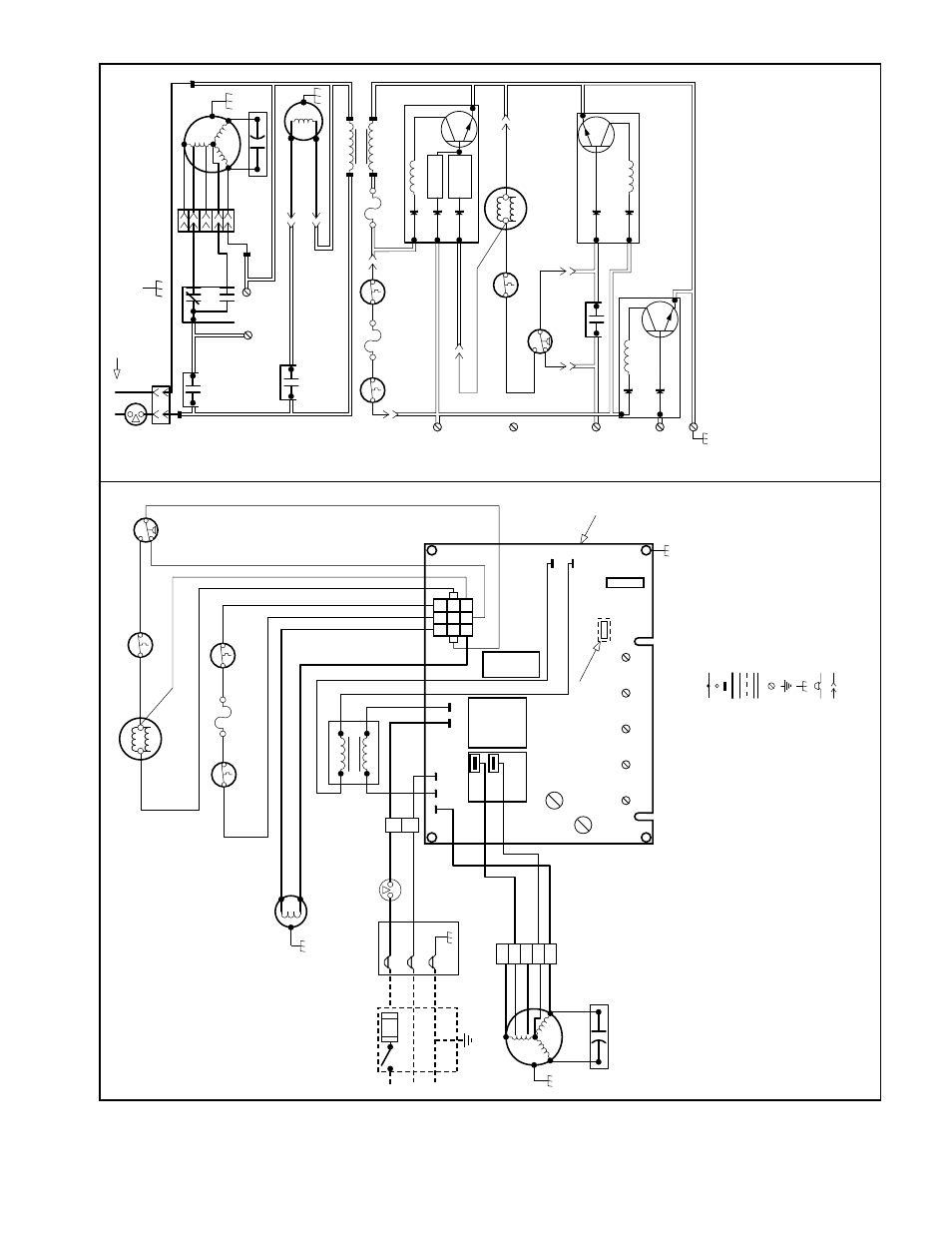

Fig. 9—unit wiring diagram – Carrier 58GFA User Manual

Page 7

Fig.

9—Unit

Wiring

Diagram

A92176

FU1

IDR

PL1-3

PR-1

PR-2

SEC-1

SEC-2

TRAN

24VAC

115VAC

BLWM

LO

MED LO

MED HI

HI

COM

CAP

L2

COM

4

3

2

1

C

CFR

HFR

PL4

NOTE#4

NOTE#8

EAC-1

EAC-2

L1

ILK

EQUIPMENT GROUND

TO 115V AC FIELD DISCONNECTIONS

NOTE #5

NOTE#10

PL2

L1

L2

PL1-1

IDR

PL1-4

ALS

FL

LS

PL1-7

R

Y

W

G

C

NOTE #1

CFR

NOTE #10

PL1-2

PL1-6

NC

NO

PRS

C

DSS

TH

TR

PILOT

MGV

GV

PL1-8

TIME

DELAY

LOGIC

HFR

3A

FUSE

PL1-9

(WHEN USED)

NOTE #7

SCHEMATIC

DIAGRAM

MGV

1

4

7

2

5

8

3

6

9

BLWM

MED LO

MED HI

HI

COM

LO

CAP

PRS

C

NO

NC

DSS

BRN

TH

PILOT

GV

TR

ALS

(WHEN USED)

NOTE #7

FL

LS

ORN

YEL

BRN

BLU

RED

BLK

RED

BLU

BLK

BLK

BLU

RED

WHT

TRAN

WHT

ILK

NOTE #5

WHT

BLK

IDM

GRN

JB

GRN

BLK

WHT

FU2

FUSED DISCONNECT

SWITCH (WHEN REQ'D)

BRN

BRN

WHT

BLK

RED

WHT

BLK

COM

PR2

L2

L1

PR1

HFR

CFR

LO

HI

NOTE #10

EAC-1

EAC-2

W

Y

R

C

G

NOTE #9

PCB

NOTE #1

GROUND

SCREW

REQ'D

FU1

3AMP

FUSE

NOTE #8

SEC-1

SEC-2

IDR

PL1

CONNECTION

DIAGRAM

JUNCTION

TERMINAL

PCB TERMINAL

FACTORY POWER WIRING (120VAC)

FACTORY CONTROL WIRING (120VAC)

FIELD POWER WIRING (120VAC)

CONDUCTOR ON PCB

FIELD WIRING SCREW TERMINAL

FIELD GROUND

EQUIPMENT GROUND

FIELD SPLICE

PLUG RECEPTACLE

AUX. LIMIT SWITCH (OVER TEMP), SPST-(N.C.),

MANUAL RESET

BLOWER MOTOR

CAPACITOR

COOLING FAN RELAY, SPDT

DRAFT SAFEGUARD SWITCH, SPST-(N.C.), MANUAL RESET

ELECTRONIC AIR CLEANER CONNECTION (115VAC)

ELECTRONIC AIR CLEANER CONNECTION (COMMON)

FUSE, 3 AMP, AUTOMOTIVE BLADE TYPE

FUSE, FIELD INSTALLED

FUSIBLE LINK

GAS VALVE, (REDUNDANT)

HEATING FAN RELAY, SPST (N.O.)

INDUCED DRAFT MOTOR

INDUCER DRAFT RELAY, DPST-(N.O.)

BLOWER DOOR INTERLOCK SWITCH, SPST-(N.O.)

JUNCTION BOX

LIMIT SWITCH (OVER TEMP), SPST-(N.C.), AUTO RESET

PRINTED CIRCUIT BOARD (FURNACE CONTROL)

9-CIRCUIT CONNECTOR (PCB1)

2-CIRCUIT CONNECTOR (L1, L2)

5-CIRCUIT PLUG CONNECTOR (BLWM)

PRESSURE SWITCH, SPDT

TRANSFORMER (115VAC/24VAC)

ALS

BLWM

CAP

CFR

DSS

EAC-1

EAC-2

FU1

FU2

FL

GV

HFR

IDM

IDR

ILK

JB

LS

PCB

PL1

PL2

PL4

PRS

TRAN

LEGEND

NOTES:

1. INTERNALLY CONNECTED TO EQUIPMENT GROUND THROUGH MOUNTING SCREW.

2. IF ANY OF THE ORIGINAL EQUIPMENT WIRE IS REPLACED, USE WIRE RATED FOR

105° C.

3. BLOWER MOTOR (BLWM) & INDUCER MOTOR (IDM) CONTAIN AUTO-RESET

THERMAL OVERLOAD SWITCH.

4. BLOWER MOTOR FACTORY SPEED SELECTIONS (PL4) ARE FOR AVERAGE

CONDITIONS. SEE INSTALLATION INSTRUCTIONS FOR DETAILS ON OPTIMUM

SPEED SELECTIONS.

5. USE ONLY COPPER WIRE BETWEEN THE DISCONNECT SWITCH AND THE

FURNACE JUNCTION BOX (JB).

6. SYMBOLS ARE ELECTRICAL REPRESENTATIONS ONLY.

7. AUXILIARY LIMIT SWITCH (ALS) USED ON DOWNFLOW MODELS ONLY.

8. THE TRANSFORMER 24VAC WINDING IS PROTECTED BY A 3 AMP AUTOMOTIVE

BLADE TYPE FUSE ON THE CONTROL BOARD. A 24VAC SHORT TO GROUND

DURING INSTALLATION, CHECKOUT, OPERATION, SERVICE OR MAINTENANCE

COULD CAUSE THIS FUSE TO OPEN. DO NOT REPLACE THE 3 AMP FUSE

WITH ANY OTHER SIZE FUSE.

9. BLOWER MOTOR (BLWM) ADJUSTABLE OFF-DELAY. FACTORY SET: 120 SECS.

CUT RESISTOR: 180 SECS.

10. WHEN CFR RELAY IS ENERGIZED, HFR RELAY IS ALSO ENERGIZED.

319593-401 REV. C

RED

WHT

4

3

2

1

C

PL2

1

2

NOTE #4

PL4

IDM

IDR

7