Carrier 58GFA User Manual

Page 2

The ability to properly perform maintenance on this equip-

ment requires certain expertise, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt to

perform any maintenance on this equipment other than those

procedures recommended in the User’s Manual. FAILURE

TO FOLLOW THIS WARNING COULD RESULT IN

POSSIBLE DAMAGE TO THIS EQUIPMENT, SERIOUS

PERSONAL INJURY, OR DEATH.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equip-

ment failure, it is essential that periodic maintenance be performed

on this equipment. Consult your local dealer as to the proper

frequency of maintenance and the availability of a maintenance

contract.

Turn off the gas and electrical supplies to the unit before

performing any maintenance or service. Follow the operating

instructions on the label attached to the furnace. A failure to

follow this warning could result in personal injury.

Never store anything on, near, or in contact with the furnace,

such as:

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum

cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning com-

pounds, plastic or plastic containers, gasoline, kerosene,

cigarette lighter fluid, dry cleaning fluids, or other volatile

fluids.

3. Paint thinners and other painting compounds, paper bags

or other paper products.

A failure to follow this warning could result in corrosion of

the heat exchanger, fire, personal injury, or death.

The minimum maintenance that should be performed on this

equipment is as follows:

1. Check and clean air filter each month or more frequently if

required. Replace if torn.

2. Check blower motor and wheel for cleanliness and lubrication

each heating and cooling season. Clean and lubricate as

necessary.

3. Check electrical connections for tightness and controls for

proper operation each heating season. Service as necessary.

As with any mechanical equipment, personal injury can result

from sharp metal edges, etc., therefore, be careful when

removing parts.

AIR FILTER ARRANGEMENT — The air filter arrangement

may vary depending on the application. Refer to Table 1 or 2 for

filter size information.

Table 1—Filter Size Information for Downflow

Furnace (In.)

FURNACE

CASING WIDTH

FILTER QUANTITY

AND SIZE

FILTER

TYPE

14-3/16

(2) 16 X 20 X 1

Cleanable

17-1/2

(2) 16 X 20 X 1

Cleanable

21

(2) 16 X 20 X 1

Cleanable

24-1/2

(2) 16 X 20 X 1

Cleanable

Table 2—Filter Size Information for Upflow

Furnace (In.)

FURNACE

CASING WIDTH

FILTER QUANTITY AND SIZE

FILTER

TYPE

Side Return

Bottom Return

14-3/16

(1) 16 X 25 X 1*

(1) 14 X 25 X 1

Cleanable

17-1/2

(1) 16 X 25 X 1*

(1) 16 X 25 X 1

Cleanable

21

(1) 16 X 25 X 1

(1) 20 X 25 X 1* Cleanable

24-1/2

(2) 16 X 25 X 1*

(1) 24 X 25 X 1

Cleanable

* Factory provided with the furnace. Filters may be field modified by cutting as

required.

Never operate unit without a filter or with filter access door

removed. A failure to follow this warning could result in fire,

personal injury, or death.

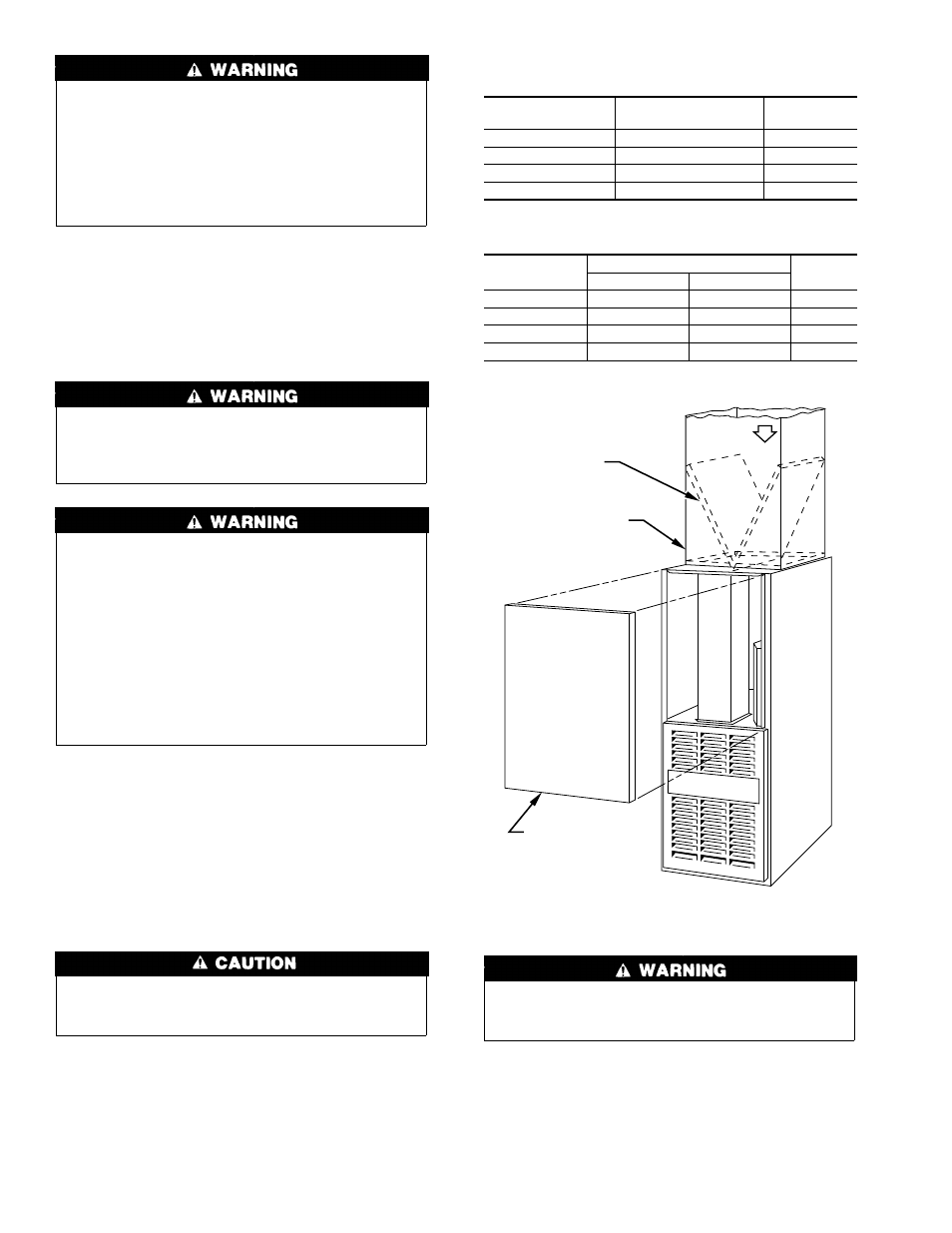

1. Downflow

Each furnace requires 2 filters which are installed in the

return-air duct. (See Fig. 3.)

To remove filters for cleaning or replacement, proceed as

follows:

a. Disconnect electrical power before removing blower access

door.

Fig. 3—Filter Positions

A88486

RETURN-AIR

PLENUM

AIRFLOW

ACCESS DOOR

INSTALLATION

POSITION

OF FILTERS

2