Mount the motor – Great Planes Spirit of St. Louis ARF - GPMA1151 User Manual

Page 14

❏

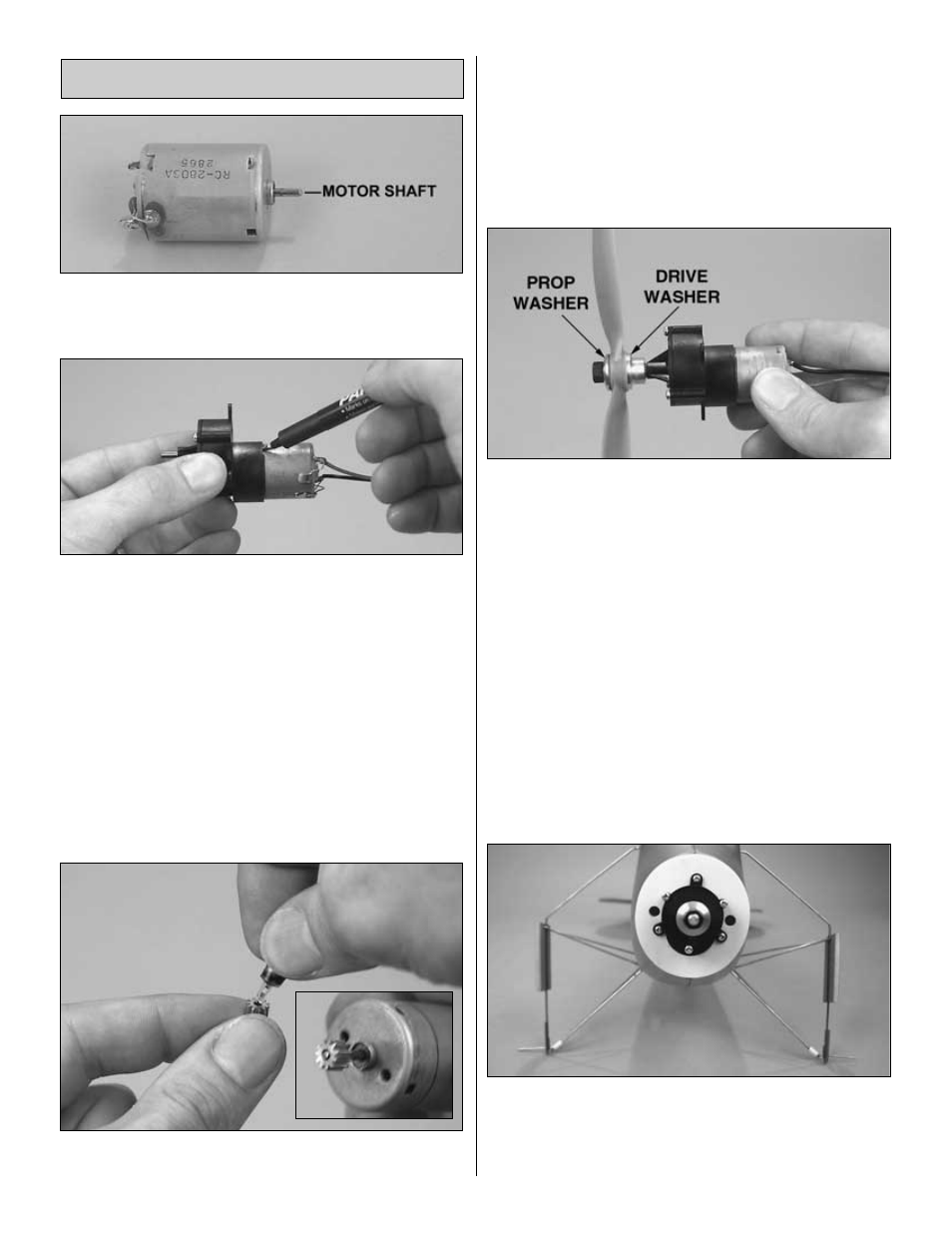

1. Use denatured alcohol or other solvent to clean the

motor shaft on the motor that you will use. Roughen the

shaft with 320-grit sandpaper so glue will adhere.

❏

2. Without using tools, use your fingers to press the motor

all the way into the gearbox. Spin the shaft on the gearbox.

If there is resistance and the shaft does not spin freely, back

the motor out of the gearbox just enough to allow the shaft

to spin freely. Use a fine-point felt-tip pen to mark the motor.

This is how far the motor is to be installed after the pinion

gear is mounted.

❏

3. Remove the motor from the gearbox.

❏

4. The pinion gear fits onto the motor shaft easier one

way than it does the other. Using only your fingers (no

tools), determine which way is the easiest by test-fitting the

gear onto the shaft. The “easy way” is the way the gear goes

on and is to be permanently installed.

❏

5. Remove the pinion gear from the motor. Add a small

drop of the cement included with this kit to the hole in the

end of the gear that fits onto the shaft. Install the gear onto

the shaft. The end of the gear should be even with the end

of the motor shaft.

❏

6. Use a toothpick to apply a small dab of lubricating oil

to both ends of the motor shaft where it exits the motor. Do

not apply oil directly from the container because you may

apply too much.

❏

7. Reinstall the motor into the gearbox up to the line you

marked. If the motor does not fit tightly in the gearbox, use

a drop of CA to hold it in position. Fit the prop adapter to the

gearbox. Insert the appropriate nylon spacer ring into the

prop, then test fit the prop to the gearbox (be certain to use

the prop washer). If necessary, use a hobby knife to enlarge

the hole in the nylon spacer ring so it will fit onto the prop

adapter.

❏

8. Tighten the prop nut with an 8mm wrench. If

necessary, use a pliers to hold the drive washer while

tightening the prop nut. Wrap the drive washer with a cloth

to keep the pliers from marring it.

❏

9. Spin the propeller by hand. It should spin somewhat

freely, but due to the resistance of the motor and gear drive,

the propeller should not “coast” or freewheel indefinitely. If

there is much resistance, back the motor out of the gearbox

until the propeller spins as it should.

❏

10. Remove the propeller from the gearbox. Position the

motor and gearbox on the firewall. Using the holes in the

mounting tabs on the gearbox as a guide, drill three 1/16”

holes through the firewall for the mounting screws. Mount

the gearbox to the firewall with three wood screws.

Mount the Motor

14