Join the wing panels, Add wing sheeting – Great Planes Dazzler 40 Kit - GPMA0480 User Manual

Page 9

9

❏

10. Remove the wing panel from the plan and set it

aside. Follow steps 2 - 9 to build the left wing panel using

the extra pieces you cut previously.

Join the Wing Panels

❏

1. Pin both wing panels down onto the plan, checking the

alignment of each panel. Test fit the die-cut 1/8" ply leading

and trailing edge joiners and the four 1/16" x 1/4" x 6-1/2"

ply main spar joiners in the wing. Test fit the die-cut

plywood servo tray between the R1 ribs. Use a metal

straightedge to make sure the spars, leading edge and

trailing edge are aligned and straight. When everything fits

well, glue the servo tray to both R1 ribs, then remove the

joiner pieces in preparation for gluing.

❏

2. Be sure the wing is right-side up and flat on the

workbench. Use 30-minute epoxy to glue the leading and

trailing edge joiners in position. Next, install the top and

bottom main spar joiners, also using 30-minute epoxy.

Double check that there is no twisting or bowing and that

everything is straight before the epoxy cures.

Add Wing Sheeting

Be sure the wing is pinned flat on your work surface

from the spar to the trailing edge before you begin

sheeting.

❏

1. Glue a 1/16" x 1-1/8" x 24" trailing edge sheet to the

top of both wing panels.

❏

2. Trim the four 1/16" x 3" x 30" balsa leading edge

sheets to 24". Save the leftover 6" pieces for use later

during construction. Cut the 3" x 24" pieces down to 2-3/8" x

24". Save the 5/8" x 24" sticks to make the R1 cap strips.

❏

❏

3. Align a leading edge sheet with a wing tip, then

hold it tightly against the leading edge while using thin CA

to glue it to the sub-leading edge. (See photo at step 5.)

❏

❏

4. Carefully lift up the leading edge sheet, away from

the ribs. Working quickly, apply a bead of medium or thick

CA to each rib, then roll the sheet into contact. Hold the

sheet until the CA cures. Wick some thin CA between the

sheet and the spar to glue the aft edge of the sheet to

the spar.

❏

❏

5. Glue a scrap piece of 1/16" x 1/2" x 2" balsa to the

bottom edge of the leading edge sheet at the root end to

reinforce the joint between the leading edge sheets. Sheet

the other top leading edge by repeating steps 3 and 4.

❏

❏

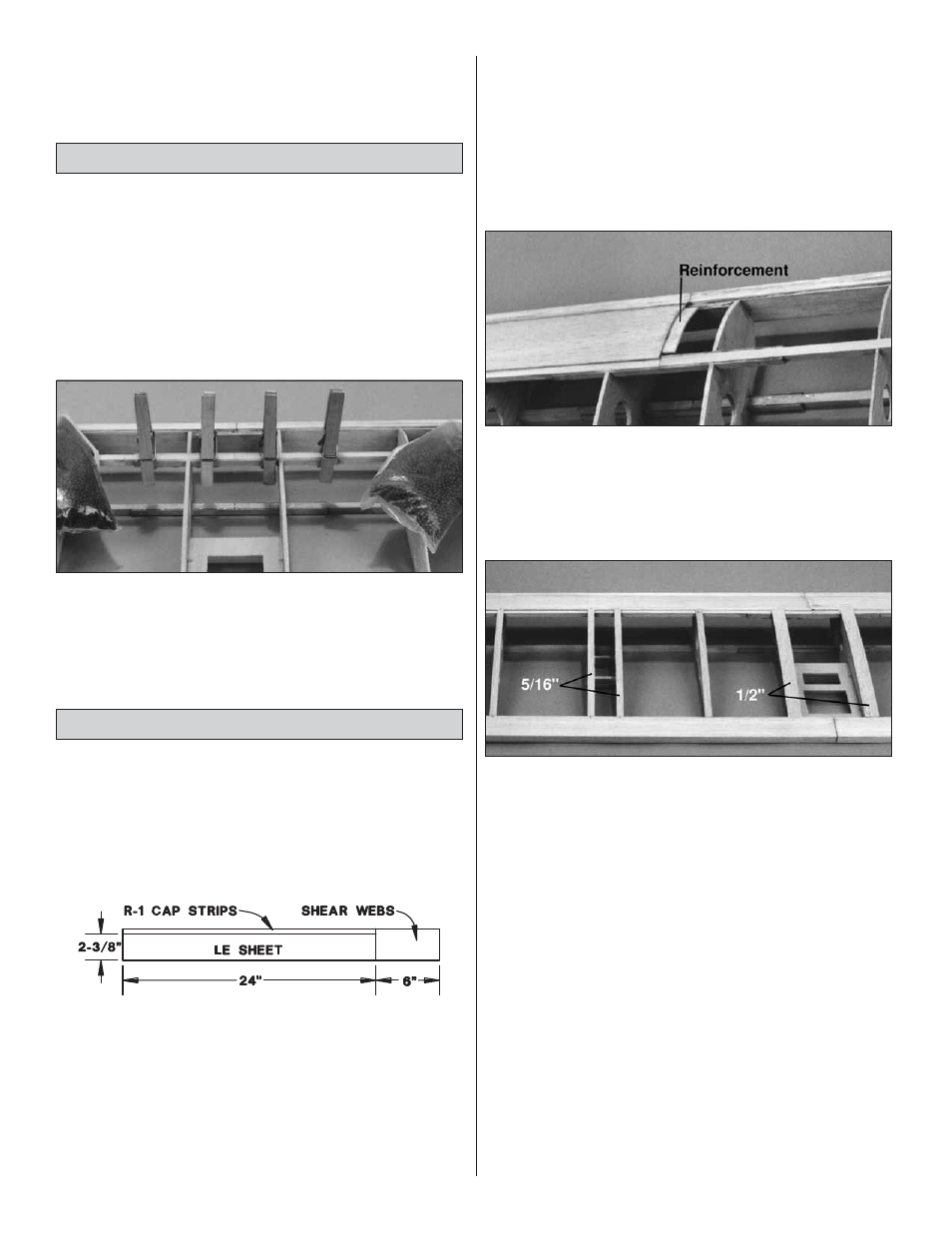

6. Cut and install cap strips for the top of each R2

and R3 rib from 1/16" x 5/16" x 30" balsa sticks. Use the

1/16" x 1/2" x 24" balsa left over from the leading edge

sheeting to make the R1 cap strips. Refer to the photo and

plan for the correct position of the root and tip cap strips.

❏

❏

7. Use the leftover 1/16" x 3" x 6" leading edge

sheeting to cut and install shear webs on the aft edge of the

spars as shown on the plan.

❏

❏

8. Remove the wing from your work surface. Pin it

back to your building board, upside-down, making sure it’s

straight without any twists.

❏

9. Repeat steps 3 - 8 to sheet the bottom of the wing.

❏

10. Use the leftover cap strip balsa to frame the servo

openings on the bottom of the wing as detailed on the plan.