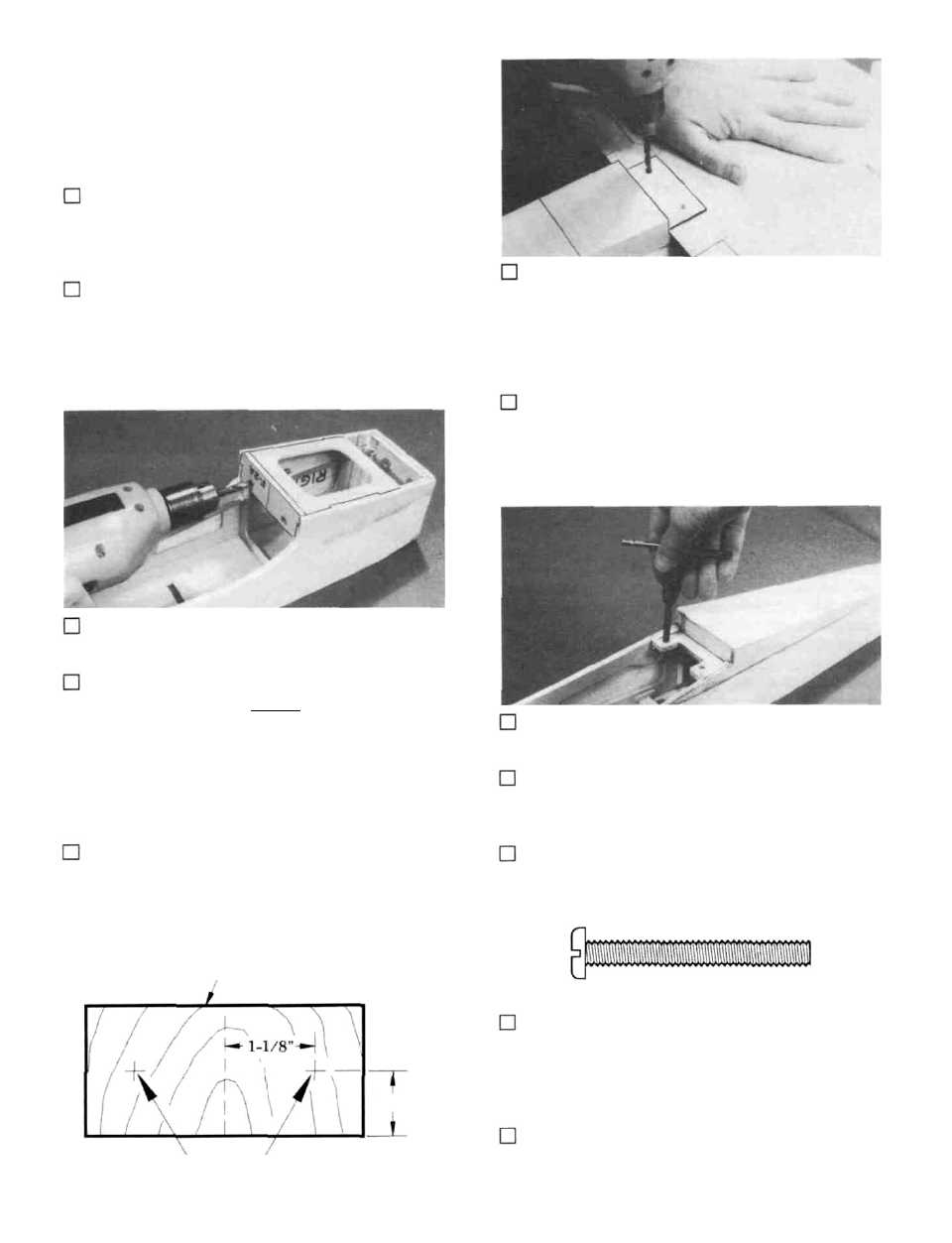

1/16" wing bolt plate drilling locations – Great Planes Ultra Sport 60 Kit - GPMA0420 Pages 1-27 User Manual

Page 24

meter" or by measuring down to the flat surface from the

center of the leading and trailing edges. The measurements

should be the same (zero degrees incidence). CAUTION: If

your flat surface is not level, you will get erroneous incidence

readings! If you are working on a flat surface that is not level,

you must set the wing incidence the same as your flat surface.

7. After making the necessary corrections to align the

wing, tack glue F-2A to F-2 with a couple drops of CA. Also

make alignment marks on the wing TE and the front ofF-4

so you may easily re-align the wing later.

8. Remove the wing and securely glue F-2A in place by

flowing thin CA into the wing dowel holes and around the

edges. Follow up with thick CA in any gaps around the edges.

12. Holding the wing firmly in place, drill 13/64" holes

at the locations you marked in step 11, drilling down through

the 1/16" ply wing bolt plate and through the 1/4" ply hold-

down block in the fuselage. Try to drill straight in, perpen-

dicular to the 1/16" ply bolt plate. IMPORTANT!: Do not

allow the wing to move while drilling!

9. Drill 1/4" holes through F-2 using the holes in F-2A as

a guide.

10. Use a pliers to grasp the ends of the wing dowels and

pull them out. Now you may slightly round (or chamfer) the

ends of the dowels for easier insertion into F-2A. Mix up a

batch of 30-minute epoxy, use a long stick to work some

epoxy into the dowel holes, smear epoxy on the dowels, then

re-insert the dowels into the wing, leaving them protrude

3/8". Wipe away all excess epoxy, then allow the epoxy to

fully harden.

only to 1/4".

14. Use a 1/4-20 tap and a tap wrench to cut threads in

the ply hold-down block in the fuselage.

15. Harden the threads in the hold-down block with thin

CA glue, then re-tap the threads after the glue is completely

dry.

13. Remove the wing and re-drill the holes in the wing

11. Study the wing plan to determine where the wing

16. Trial fit the wing to the fuse using the two 1/4-20

bolt holes are to be drilled. By measuring, transfer the loca-

tions to the wing bolt plate on the bottom of the wing. After

marking the bolt locations, replace the wing in the saddle and

re-align it accurately, as in step 6.

1/16" WING BOLT PLATE

Drilling locations

nylon bolts provided. You may cut the bolts off to their proper

length, so they protrude about 1/4" below the hold-down

block in the fuselage.

1/4 - 20 Nylon Wing Bolt

17. Later you will apply foam wing seating tape or

silicone sealer to the wing saddle. To allow space for this

wing cushion material, you may sand the saddle slightly in

the areas where the wing touches the saddle, to provide a

small gap.

18. Sand off the bottom edge of F-2 and F-2A flush with

the bottom of the chin block base. And, while you're at it,

13/16"

24