Great Planes HyperFlow Ducted Fan System - GPMG3910/3911 User Manual

Page 5

5

❏

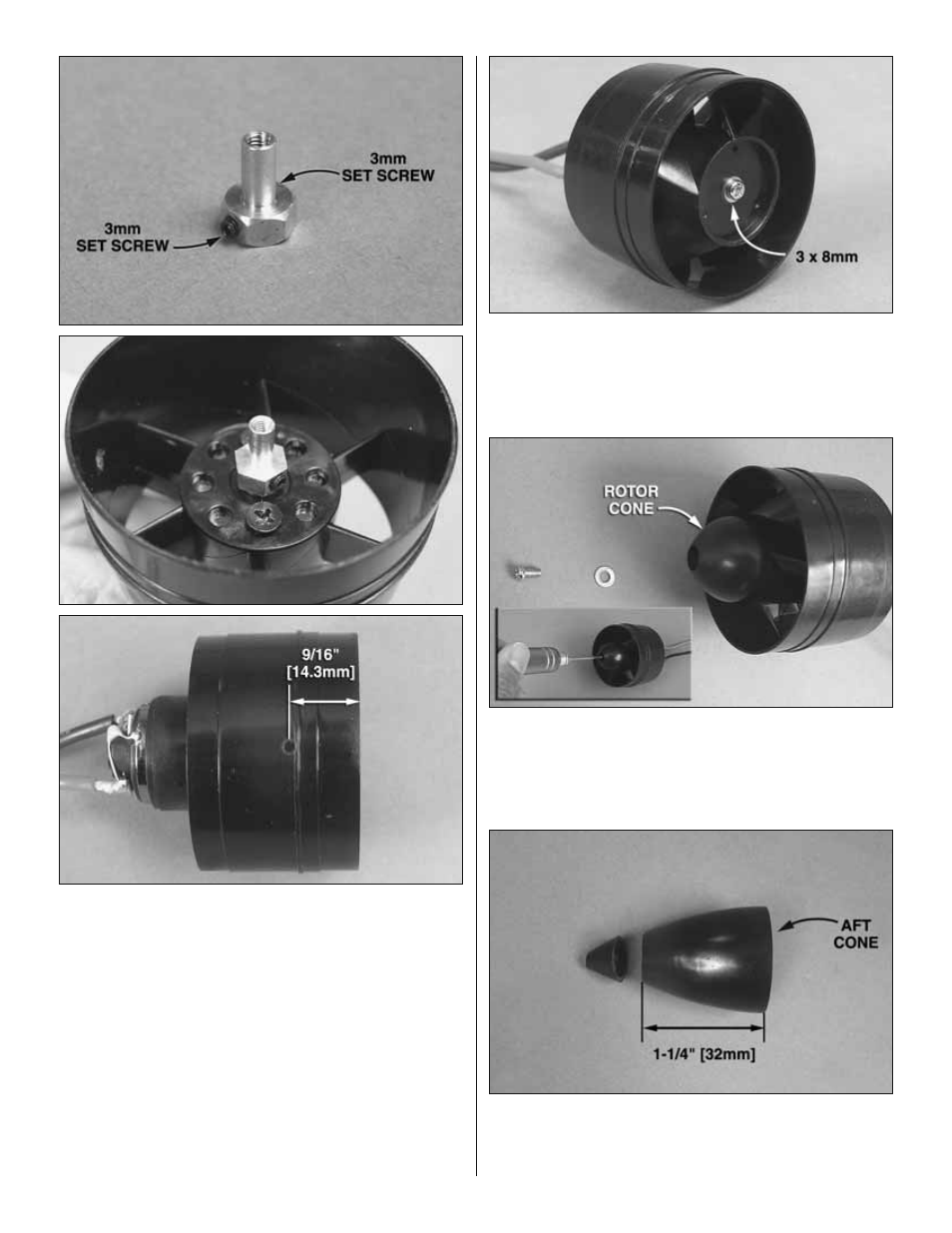

3. Press the 2mm fan rotor adapter onto the motor. Using

threadlocking compound, tighten the set screws against the

motor shaft. Allow a small amount of clearance (1/8" [3mm])

between the base of the adapter and the motor to prevent

binding. A 3/32" [2.4mm] hole can be drilled into the side of

the fan housing 9/16" [14.3mm] from the front edge to insert

an allen wrench for the fan adapter set screws.

❏

4A. Fit the fan rotor over the brass fan adapter and push

it down so it is fully seated. If you will not be installing the

optional rotor cone, thread a 3 x 8mm Phillips screw with

a 3mm washer through the fan adapter. Be sure to use

threadlocking compound.

❏

4B. If you are installing the optional rotor cone, press it

onto the fan rotor as shown. Insert a 3 x 8mm Phillips screw

and 3mm washer (with threadlocking compound) into the

hole in the rotor cone and tighten the screw into the brass

fan adapter.

❏

5. Cut a portion of the aft cone away for motor cooling and

to allow the motor leads to pass through. For most motor

applications, the aft cone should be approximately 1-1/4"

[32mm] long after cutting it.