Performance, Technical information – Great Planes HyperFlow Ducted Fan System - GPMG3910/3911 User Manual

Page 2

PERFORMANCE

The following measured performance data has been achieved using the stock intake lip and 90% FSA exhaust duct.

# LiPo Cells

Voltage

Current

Power

Static Thrust

RPM

Effl ux

Effl ux

Speed Speed

Motor: Brushed Speed 370BB (GPMG3910)

(meters/second)

(miles/hour)

3

11.1V

10.3A

114W

240g (8.5oz)

29,000

32 m/s

72 mph

Motor: Brushless 20-40-3500 (GPMG5140)

2

7.4V

8.7A

64W

215g (7.6oz)

27,000

28 m/s

63 mph

3

11.1V

15.7A

174W

400g (14.2oz)

35,800

46 m/s

103 mph

Motor: Brushless 24-33-4875 (GPMG5170)

2

7.4V

17.2A

127W

330g (11.6oz)

32,300

41 m/s

92 mph

Motor: Brushless 24-45-3790 (GPMG5185)

2

7.4V

9.7A

72W

230g (8.0oz)

27,120

28 m/s

63 mph

3

11.1V

19.9A

221W

485g (17.1oz)

38,600

53 m/s

118 mph

4

14.8V

32.6A

482W

820g (28.9oz)

48,000

74 m/s

165 mph

Effl ux Speed: Air Speed Exiting at the Exhaust

Please visit the Great Planes website (www.greatplanes.com) for performance

data on recently released motors or any other technical updates.

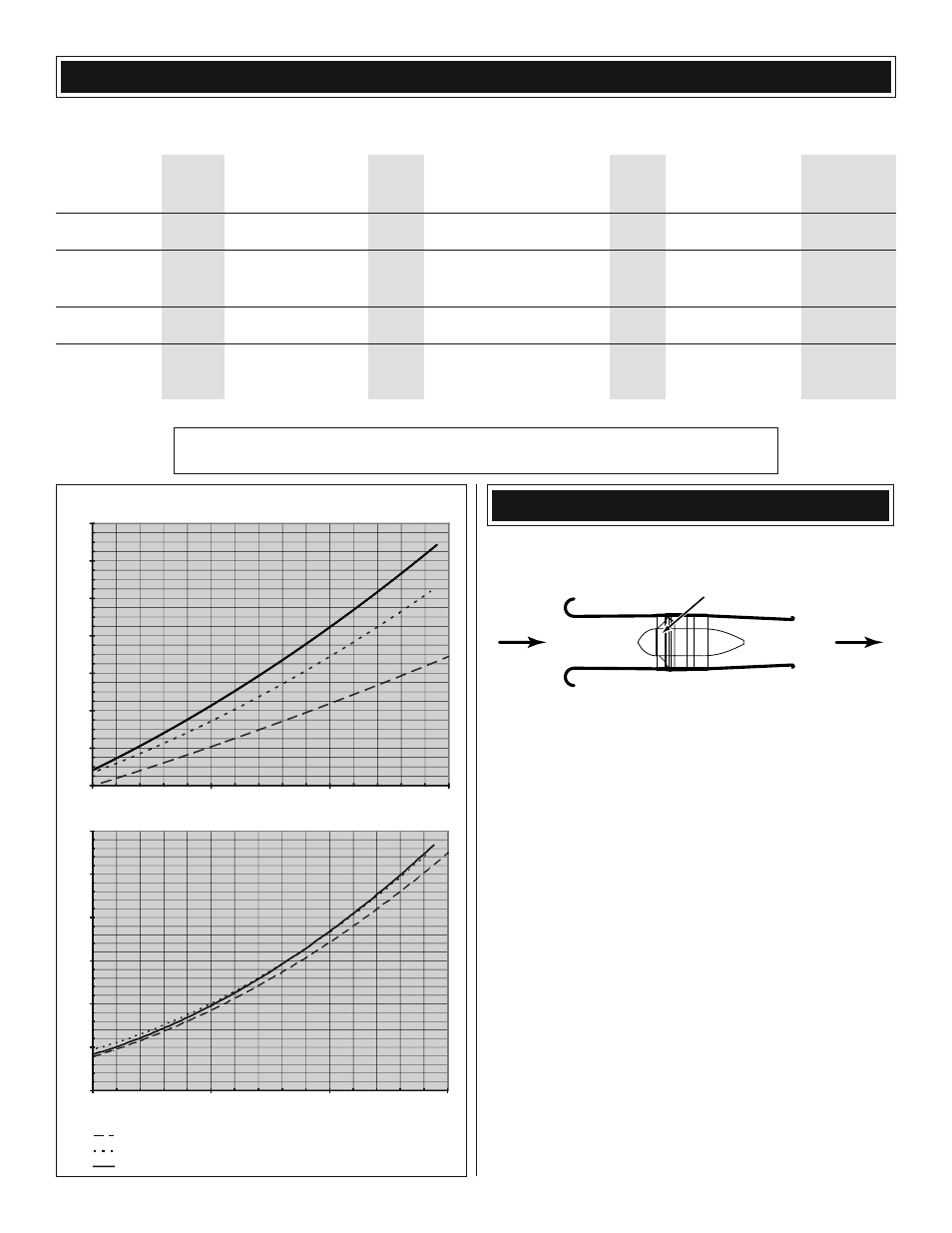

Hyperflow 56mm Measured Performance

134% FSA

99% FSA

90% FSA

Efflux Speed (mph)

Thrust (oz)

40

20000

30000

40000

50000

RPM

20000

30000

40000

50000

RPM

60

80

100

120

140

160

0

5

10

15

20

25

30

180

2

The data in these charts was obtained using

a stock intake lip. The motor was an Ammo

24-45-3790 and the ESC was an SS-35.

TECHNICAL INFORMATION

Duct Cross-Section

INTAKE

Fan Swept Area

EXHAUST

The way a ducted fan works is simple: As the fan rotates

and draws air, the surrounding duct causes the airfl ow to

accelerate through the fan and exit out of the exhaust tube.

With this in mind, fans are designed with a particular duct

profi le in mind and a particular fl ying speed. The HyperFlow

has been designed to be most effi cient while fl ying at 56 mph

[90 km/h]. This was done so that the fan would perform well

with an inexpensive brushed motor, but would still operate

at effi cient levels with a brushless motor. This is proven by

the maximum measured thrust of 28.9oz and 165mph effl ux

speed at 48,000rpm.

The duct profi le is extremely important for the fan to perform

well. The intake needs to be large enough to supply the

required air to the fan at both low and high speeds and

at different rpm, but if the duct profi le is too large, it may

increase the airplane's drag coeffi cient. Of course, the intake

and exhaust should be as short as possible to minimize

losses. The duct profi le must be smooth and absolutely free

of obstacles. It is also recommended that the intake has a

smooth, rounded lip which helps maximize static thrust and

smooth airfl ow into the intake.